70 duster: updating, and a no-dough pro-touring makeover

its been like an early christmas around here these past two weeks. a very expensive early christmas, but a good one.

first up, budget before was 7132.15

since i got the 442 done, i spent the payday. well qualify these two purchases under spending the good money.

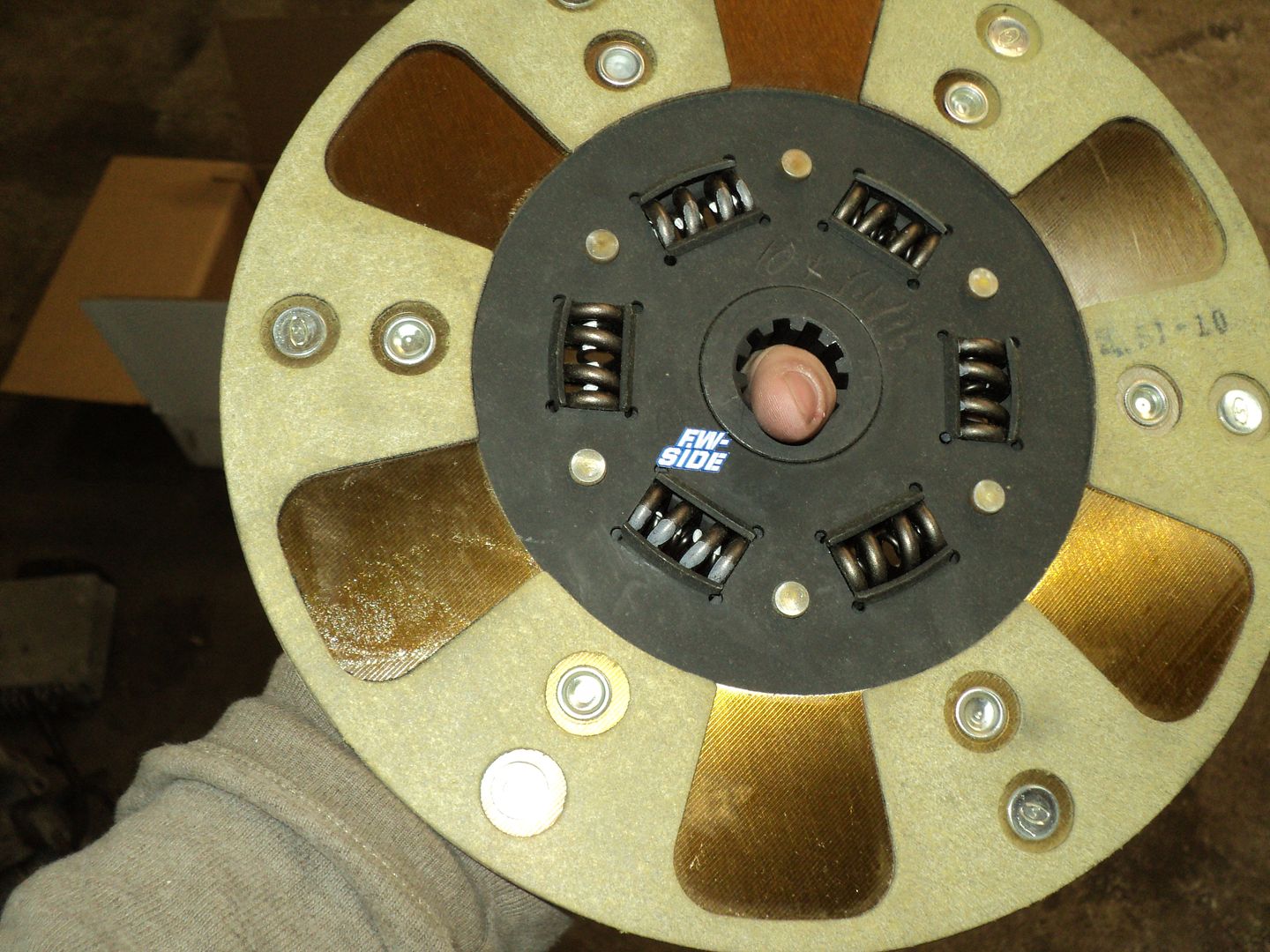

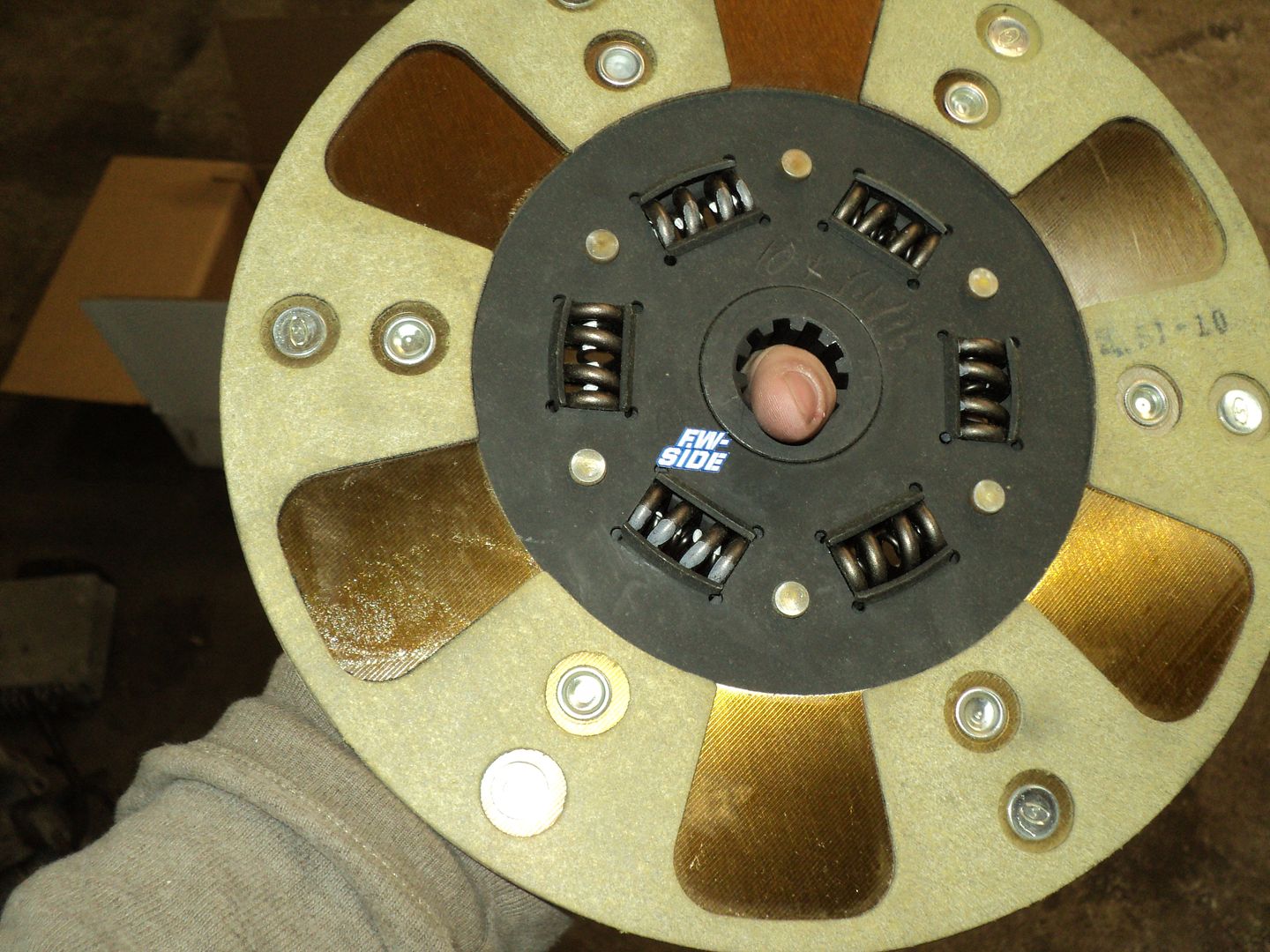

first, i ordered my new clutch kit. spec stage 2+. used a throwout bearing for a late 90's jeep 4.0 5 speed wrangler, as it fits the tremec and mopar fork together like it was made to. also had them build my disc with a 10 spline pattern, and the pressure playt for the mopar. 10.5 clutch, good to 600 horse on slicks. will give me room to grow for when i get the rest of the car sorted enough for a centrifugal supercharger. this set me back $440. ive used probably 10-12 spec clutches in various cars over the past decade since i opened my own buisness. great clutches for abuse. the stage 2 thats in the car now has had great pedal effort (very light), no chatter, and bever slipped. i could have gotten away with just a disc swap, but decided that this was a big enough job already, and id like to do it with all new parts. would NOT want to have to change clutches again. i delt with matt rocksvold down there for the whole order. great guy, and a mopar fanatic to boot. id recommend him to anyone calling spec.

i also dealt with tony edler, of www.globaloverdrive.com for my crossmember. i had origonally planned on making my own, but decided to spend the good money. this is the newest crossmsmber for the tremec swaps on the market, and is designed to retain the structural rigiodity of the t-bar crossmember. im probably still going to stitch weld the t-bar crossmember to the floor pan if i can get the undercoating off and get a good weld, just for anal-retentiveness sake. this set me back $241, and came with all the nuts and bolts, as well as the trans tunnel template for cutting. he has been very helpful, and a bery nice guy to talk to on the phone. the crossmember came well welded, with interlocking tabs, and powedercoated to boot. nice piece. looking forward to seeing how it works.

i also dropped the input bearing retainer off at the machine shop last night. hollis page at hp engines (of engine masters fame) is turning it down to fit in the stock hole on my lakewood bellhousing.

also, i got the steel for my trans tunnel patch. it was free. i dont have a picture, but go look at the top of your dryer, and youll get the idea of where it came from.

all thats left to secure is:

mustang pilot bearing for making the hybrid

trans rubber isolation mount

mustang electrical connectors for the tremec

gear oil

new budget total: 7813.15

im still debating yanking the motor to fix my leaking pan gasket and give everything a good cleaning while im at it. i just really, really dont want to pull the motor. ive got enough things to do and stress without adding that.

also, need advice:

i have never successfully dialed in a bellhousing. id like to get this one right. how in the heck do i do that?

and y'all make sure to enjoy those that you love during christmas. and every other day of the year too. theyre the best GIFTS you'll ever get. (a gift is freely given, with no expectations of return. those that love us dont have to, they choose to. same with those that we love. sermon done now...)

michael

its been like an early christmas around here these past two weeks. a very expensive early christmas, but a good one.

first up, budget before was 7132.15

since i got the 442 done, i spent the payday. well qualify these two purchases under spending the good money.

first, i ordered my new clutch kit. spec stage 2+. used a throwout bearing for a late 90's jeep 4.0 5 speed wrangler, as it fits the tremec and mopar fork together like it was made to. also had them build my disc with a 10 spline pattern, and the pressure playt for the mopar. 10.5 clutch, good to 600 horse on slicks. will give me room to grow for when i get the rest of the car sorted enough for a centrifugal supercharger. this set me back $440. ive used probably 10-12 spec clutches in various cars over the past decade since i opened my own buisness. great clutches for abuse. the stage 2 thats in the car now has had great pedal effort (very light), no chatter, and bever slipped. i could have gotten away with just a disc swap, but decided that this was a big enough job already, and id like to do it with all new parts. would NOT want to have to change clutches again. i delt with matt rocksvold down there for the whole order. great guy, and a mopar fanatic to boot. id recommend him to anyone calling spec.

i also dealt with tony edler, of www.globaloverdrive.com for my crossmember. i had origonally planned on making my own, but decided to spend the good money. this is the newest crossmsmber for the tremec swaps on the market, and is designed to retain the structural rigiodity of the t-bar crossmember. im probably still going to stitch weld the t-bar crossmember to the floor pan if i can get the undercoating off and get a good weld, just for anal-retentiveness sake. this set me back $241, and came with all the nuts and bolts, as well as the trans tunnel template for cutting. he has been very helpful, and a bery nice guy to talk to on the phone. the crossmember came well welded, with interlocking tabs, and powedercoated to boot. nice piece. looking forward to seeing how it works.

i also dropped the input bearing retainer off at the machine shop last night. hollis page at hp engines (of engine masters fame) is turning it down to fit in the stock hole on my lakewood bellhousing.

also, i got the steel for my trans tunnel patch. it was free. i dont have a picture, but go look at the top of your dryer, and youll get the idea of where it came from.

all thats left to secure is:

mustang pilot bearing for making the hybrid

trans rubber isolation mount

mustang electrical connectors for the tremec

gear oil

new budget total: 7813.15

im still debating yanking the motor to fix my leaking pan gasket and give everything a good cleaning while im at it. i just really, really dont want to pull the motor. ive got enough things to do and stress without adding that.

also, need advice:

i have never successfully dialed in a bellhousing. id like to get this one right. how in the heck do i do that?

and y'all make sure to enjoy those that you love during christmas. and every other day of the year too. theyre the best GIFTS you'll ever get. (a gift is freely given, with no expectations of return. those that love us dont have to, they choose to. same with those that we love. sermon done now...)

michael