swisswill

Well-Known Member

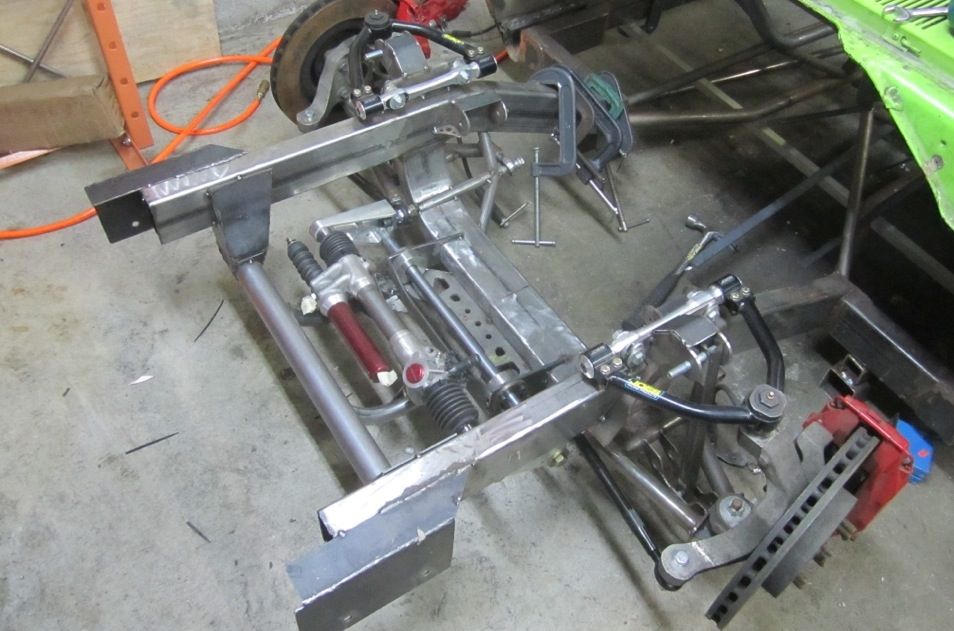

Thanks a bunch. I haven't even gotten to the real good stuff yet. So much more fab to do, then bodywork, then fun stuff...

While that's not the intent, I'd be lieing if I said that thought had not crossed my mind.

I think it would be great if the "average joe" garage builder was able to get a rag to follow his build with the occasional published update. Almost guaranteed to sell subscriptions AND inspire all the other average joe's out there. The high dollar, super money, fancy shop builds are awesome to look at and gawk over, but the inspiring stuff, for me, comes out of the random guys garage. Go market and sell that bad boy Denny... You got that!

Thanks John, and yes, long way but the only way, outside raising the body... By the way, what in the world is your ride height going to be to the rockers? I am at 5" and was thinking of you yesterday when I noticed there is only @ 3" from the top of my 275/35-18 tires to the lip of the fender mount. When my suspension is aired out, my tires will touch the fenders. I barely have enough room for the required suspension travel. Maybe with the HD k-member it's a different story but I can't imagine given that when the car is at such and such a height, there is only so much space from the ground to the fender, most of that being taken by the tire.

Hey Tin, shouldn't you be out driving somewhere???

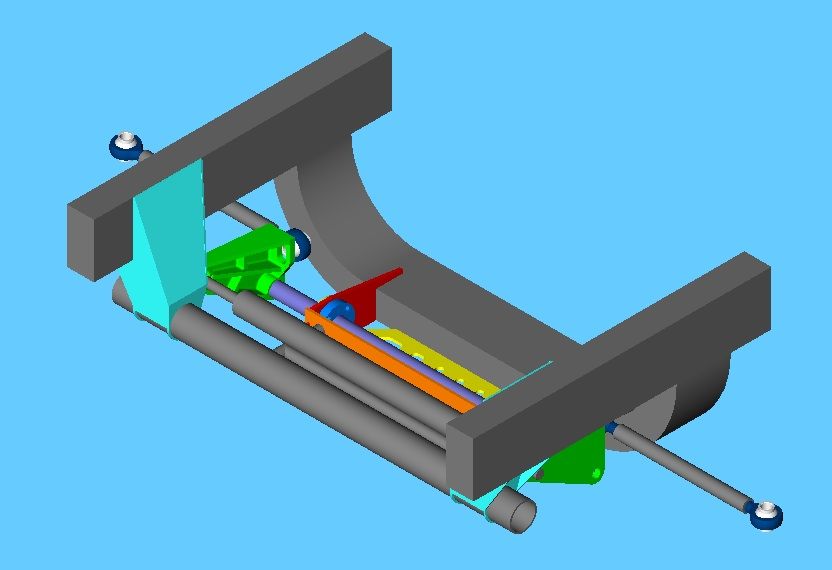

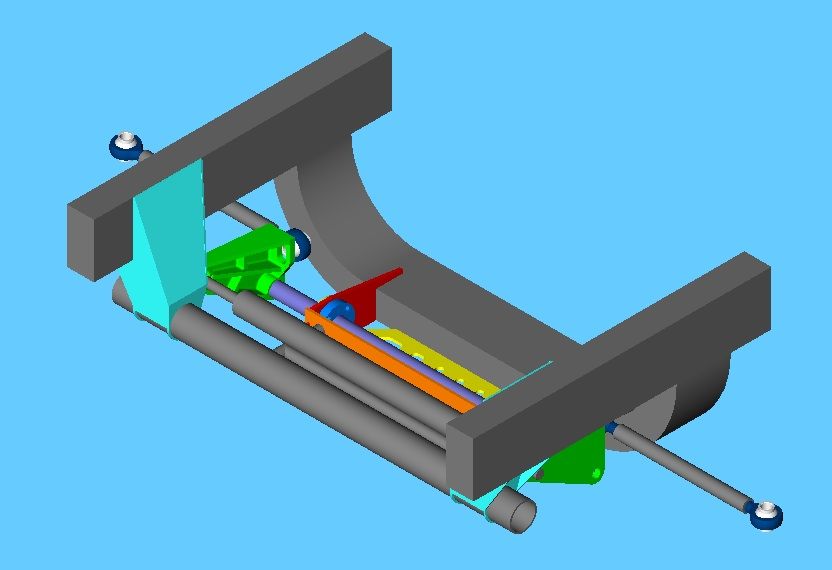

Hey Nate, good to hear from you! I did see these from TCP, Flaming River also has something similar for T-birds and Chevelles I think. I looked hard at going this route and almost copied the design but felt I needed something more stout since I had to raise the inner tie rods about 2" so I designed my own, with the input of a couple engineers.

You making any progress on your build? I'd like to see where your at.