Roller Rocker geometry questions

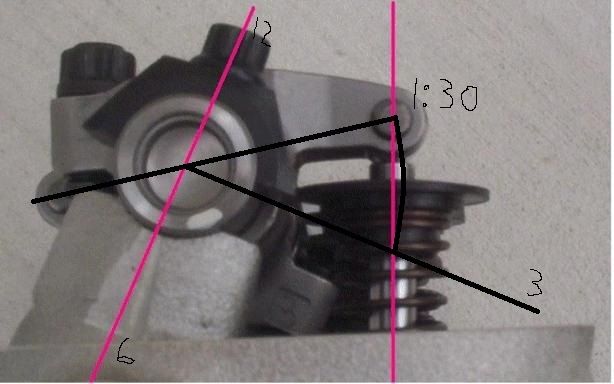

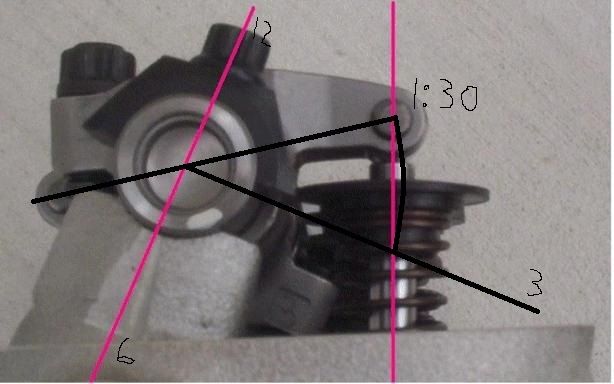

I never said anything about raising the shafts. I've been saying the opposite, that the valve tips need to be raised via longer valves or lash caps which in effect does the same thing. Look at the picture. You can see that as the rocker tip follows the trajectory of the arc, it moves toward the rocker shaft, thus moving the scrub pattern more on to the center of the valve tip.

These pics were grabbed from this thread http://www.forabodiesonly.com/mopar/showthread.php?t=41037 the heads are new OOTB. The real problem in both scenarios is that the rockers are to long for the shaft saddle to rocker tip distance. In both cases the best cheap fix is lash caps, which may not even be enough. Usually the ductile iron rockers don't have this issue. Score one for the old school.

I never said anything about raising the shafts. I've been saying the opposite, that the valve tips need to be raised via longer valves or lash caps which in effect does the same thing. Look at the picture. You can see that as the rocker tip follows the trajectory of the arc, it moves toward the rocker shaft, thus moving the scrub pattern more on to the center of the valve tip.

These pics were grabbed from this thread http://www.forabodiesonly.com/mopar/showthread.php?t=41037 the heads are new OOTB. The real problem in both scenarios is that the rockers are to long for the shaft saddle to rocker tip distance. In both cases the best cheap fix is lash caps, which may not even be enough. Usually the ductile iron rockers don't have this issue. Score one for the old school.