Project Frog Princess

I've had a long hiatus from the Dart, but have finally got back to it. The other half wanted AC. Just got done putting a high velocity system in the attic. Contortionist maneuvers in a 110 degree attic is... well I'd rather work on the Dart.

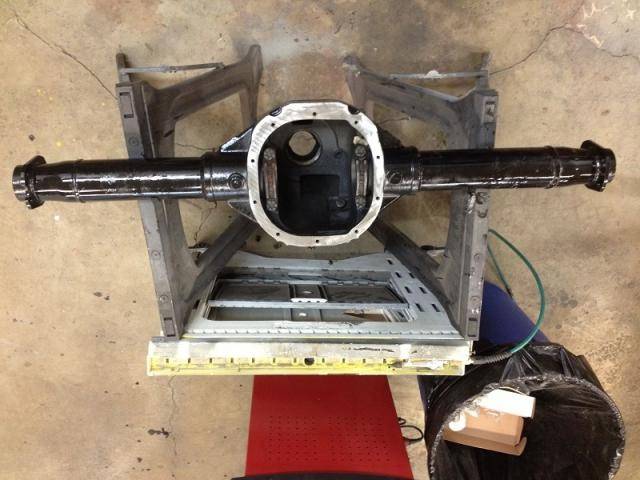

This was my first diff rebuild. I went rather well, not as hard as people make it sound. There's lots of tutorials online to help out. Here's a few pics with how I managed without a press.

The bearing remover is a must for the pinion bearings, at least if you want to use the old ones for test fitting as I did. I used a 2" flap wheel to enlarge the ID of the larger one to allow it on and off for testing purposes. For the smaller one, a woodworking sanding drum worked well. I did not measure pinion depth. The Ford 8.8 is made to have a standard depth referred to as the master housing depth. If using the same pinion, and the new rear bearing measures the same, you can use the shim that was in place and reproduce the old setting. At least that's the theory and it worked for me.

My inch pound torque wrench is a clicker, and made for higher measurements than the 15 - 30 needed to set pinion preload so I used a fishing scale (tested for accuracy first) to tug on a breaker bar at 10". 2 - 3 lb = 20 - 30 inch pounds. The advice to tighten 1/8 turn at a time is for real. I think I was under 1/8 and it jumped to 30, the upper limit. Going over would mean starting over with a new crush sleeve. To hold the pinion while applying well over 140 ft lbs I drilled a couple holes and cut a notch in a 3 foot length of angle iron.

I first set it in range with the used bearings, without the crush sleeve, then installed the carrier and adjusted the shims to get a .009 backlash. The gear pattern came out nice with no further adjustment required.

I did not have to remove carrier bearings since this was a new Yukon Duragrip. To install new bearings on it, I washed them in solvent, then Dawn dishwashing liquid, and heated them to 350 in my shop oven. They still required tapping into place with a punch. The rear pinion bearing slipped right into place with this method with no punch required.

For whatever reason, once I put new bearings on , and a crush sleeve, my backlash dropped to .005 which is too low. I moved a .005 shim from one side to the other and it was back in range at .009 with a good pattern.

To install the axles with the Yukon carrier, you just remove the side gear shaft. There's a large and small access window, the larger one provides room for C-clip installation.

I've just begun the spring relocation to frame rails so the shortened 8.8 will have a home.

I've had a long hiatus from the Dart, but have finally got back to it. The other half wanted AC. Just got done putting a high velocity system in the attic. Contortionist maneuvers in a 110 degree attic is... well I'd rather work on the Dart.

This was my first diff rebuild. I went rather well, not as hard as people make it sound. There's lots of tutorials online to help out. Here's a few pics with how I managed without a press.

The bearing remover is a must for the pinion bearings, at least if you want to use the old ones for test fitting as I did. I used a 2" flap wheel to enlarge the ID of the larger one to allow it on and off for testing purposes. For the smaller one, a woodworking sanding drum worked well. I did not measure pinion depth. The Ford 8.8 is made to have a standard depth referred to as the master housing depth. If using the same pinion, and the new rear bearing measures the same, you can use the shim that was in place and reproduce the old setting. At least that's the theory and it worked for me.

My inch pound torque wrench is a clicker, and made for higher measurements than the 15 - 30 needed to set pinion preload so I used a fishing scale (tested for accuracy first) to tug on a breaker bar at 10". 2 - 3 lb = 20 - 30 inch pounds. The advice to tighten 1/8 turn at a time is for real. I think I was under 1/8 and it jumped to 30, the upper limit. Going over would mean starting over with a new crush sleeve. To hold the pinion while applying well over 140 ft lbs I drilled a couple holes and cut a notch in a 3 foot length of angle iron.

I first set it in range with the used bearings, without the crush sleeve, then installed the carrier and adjusted the shims to get a .009 backlash. The gear pattern came out nice with no further adjustment required.

I did not have to remove carrier bearings since this was a new Yukon Duragrip. To install new bearings on it, I washed them in solvent, then Dawn dishwashing liquid, and heated them to 350 in my shop oven. They still required tapping into place with a punch. The rear pinion bearing slipped right into place with this method with no punch required.

For whatever reason, once I put new bearings on , and a crush sleeve, my backlash dropped to .005 which is too low. I moved a .005 shim from one side to the other and it was back in range at .009 with a good pattern.

To install the axles with the Yukon carrier, you just remove the side gear shaft. There's a large and small access window, the larger one provides room for C-clip installation.

I've just begun the spring relocation to frame rails so the shortened 8.8 will have a home.