Charger

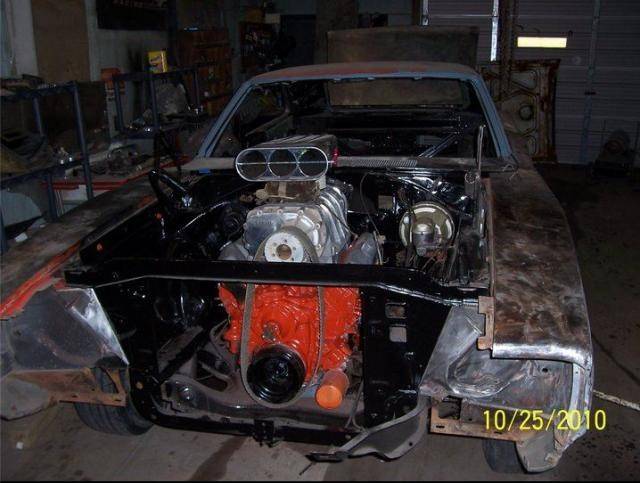

Experimenting with the orange on the engine, I haven't bothered to paint the valve covers in an effort to simulate aluminum covers later.

Another shot of the motor painted orange.

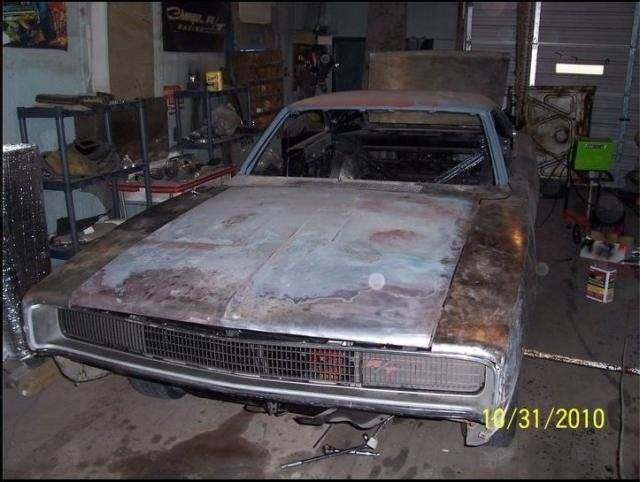

We did decide on a replacement hood. The $100 price tag was more than reasonable.

Another day, another color on the motor. Spence is leaning towards yellow as the color of choice now. SBC valve covers (although they obviously don't fit) are placed on the engine to help us decide whether or not we want to use chromed or polished aluminum later.

Another pic of the engine in yellow. The blower housing has been further polished, but still has a long way to go.

As nice as the replacement hood may have been, it needs to be "air-conditioned" for the supercharger clearance. Here Spence is drilling the first pilot hole to drop our reciprocating saw into.

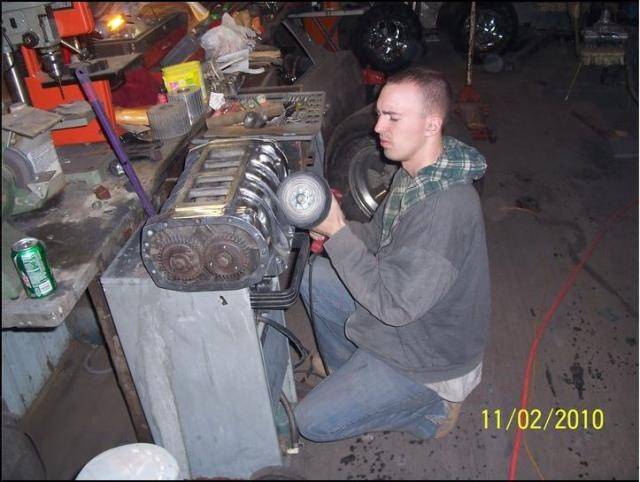

Polish, polish, polish. Dirty, time-consuming, boring, etc... etc... Probably not what most guys on military leave look forward to doing with their time off.

The expression on Spence's face says it all. - Nothing like having cotton fibers and buffing compound in your eyes, ears, nose and everywhere else.

It's not perfect, but it's looking better.

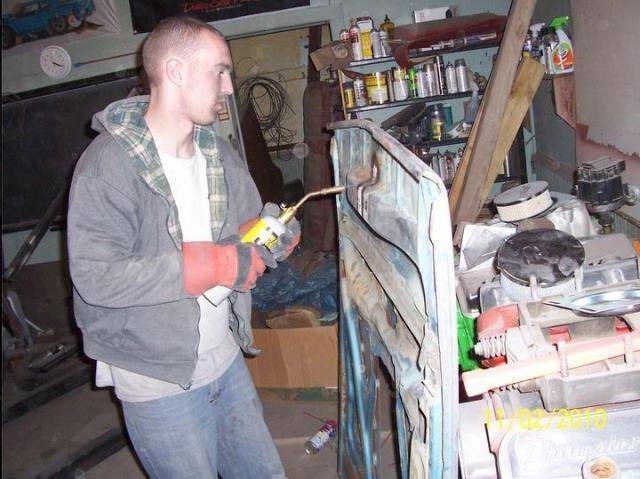

The hood was in good shape for the most part, but it had an arch in it that kept it from aligning with the grill. Here Spence is using a small propane torch to heat the center of the underside infrastructure. Once we had it hot enough we laid it down on the floor and put pressure on the topside. After repeating a few times, it fit perfect.

Experimenting with the orange on the engine, I haven't bothered to paint the valve covers in an effort to simulate aluminum covers later.

Another shot of the motor painted orange.

We did decide on a replacement hood. The $100 price tag was more than reasonable.

Another day, another color on the motor. Spence is leaning towards yellow as the color of choice now. SBC valve covers (although they obviously don't fit) are placed on the engine to help us decide whether or not we want to use chromed or polished aluminum later.

Another pic of the engine in yellow. The blower housing has been further polished, but still has a long way to go.

As nice as the replacement hood may have been, it needs to be "air-conditioned" for the supercharger clearance. Here Spence is drilling the first pilot hole to drop our reciprocating saw into.

Polish, polish, polish. Dirty, time-consuming, boring, etc... etc... Probably not what most guys on military leave look forward to doing with their time off.

The expression on Spence's face says it all. - Nothing like having cotton fibers and buffing compound in your eyes, ears, nose and everywhere else.

It's not perfect, but it's looking better.

The hood was in good shape for the most part, but it had an arch in it that kept it from aligning with the grill. Here Spence is using a small propane torch to heat the center of the underside infrastructure. Once we had it hot enough we laid it down on the floor and put pressure on the topside. After repeating a few times, it fit perfect.