m880cummins

Well-Known Member

Well I'm going to be 18 in a month and want to enjoy this car before I'm off to college next year. Started life built in LA Febuary 14, 1966 as almost fully optioned with the exception of a power rear window, rear window deflectors and a map light. Dad bought it in northern PA for $300 at auction in 1993 and it had 130,00 miles on it and no rust at all. Took 4 years rebuilding it with my help here and there whether it was handing him a tool or walking on the tinted quarter glass that was lying in the yard one day and almost giving him a heartattack lol. Had a 273 and that was rebuilt, spun a rod after 5,900 miles so a 360 crate motor went in front of a A500 lockup/overdrive and a 3:91 posi 8.75. Racked up 100,000 miles as any car should be driven. Looked great but the silent beast lurked until a the early 2000s. That silent beast was rust and the wagon is the worst for it. 75% of the body panels are inaccessible from the back side except through maybe a 1" body plug hole. Currently the car sits with quarters and tailgate rusted out and some rot along the roof and doors. Drive train is still great and interior pristene. Was a baby poop brown car with gold interior. Now red with a gold interior.

As it was in 1999:

In case you were wondering my dad's common username is pigdoc he is part of the Mopar Mailing List just like me.

From Dr Mopar's salvage, here's the new body:

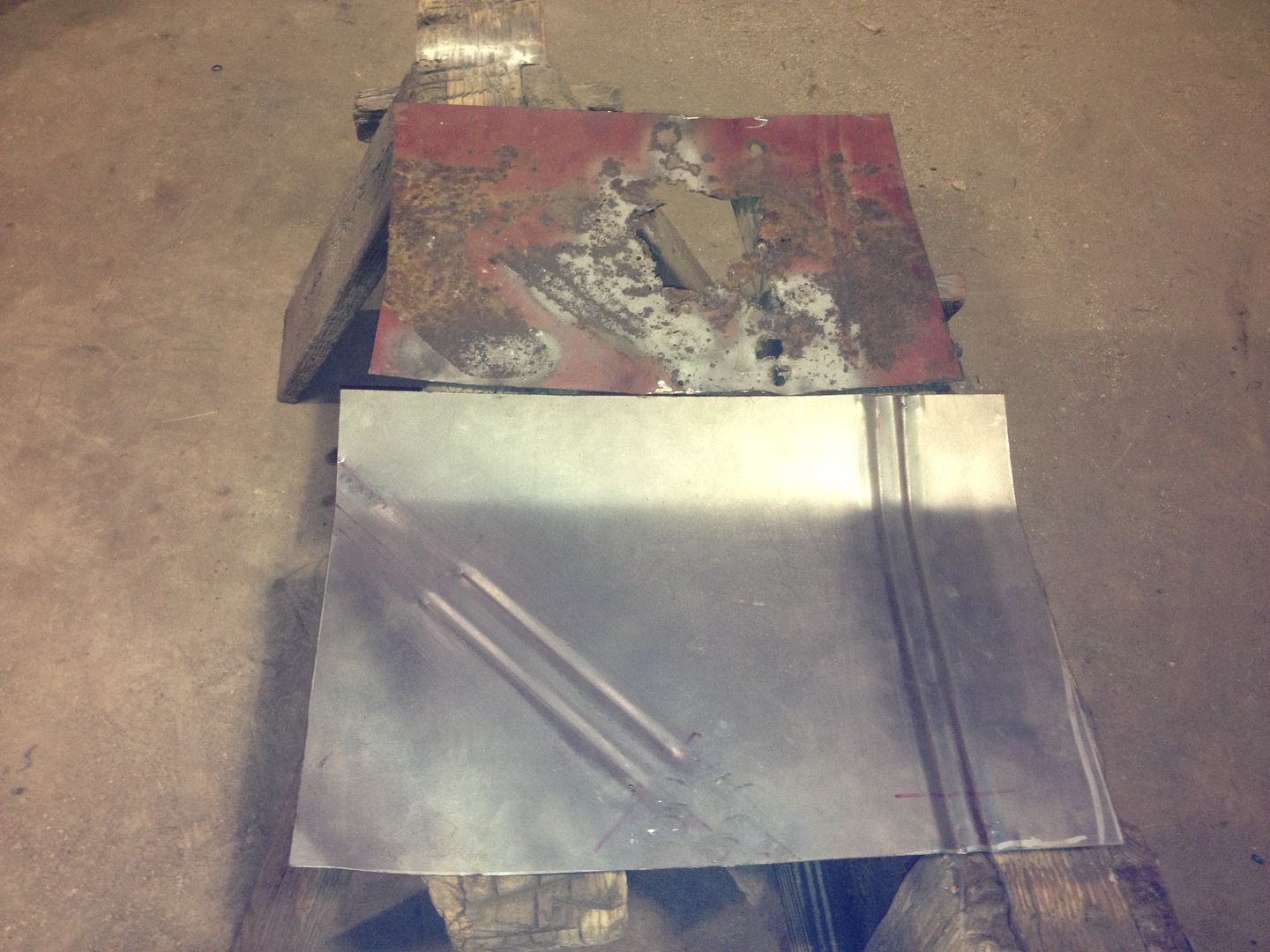

Has some quarter damage:

Since we got it in 2010, it sat on dollies as we dropped the /6 and took the suspension out. Yesterday, I completely gutted the interior, took windshield and dash out, cleaned up the inside a little and then took the junk hood off and put the good hood on and sandblasted the hinge spots and cold galvanized them and mounted it. Will be sending it to get soda blasted later this month. I'm taking the project on mostly by myself as I think I have enough experience now after doing 2 trucks:

My 1977 M880 with a cummins 5 speed D60/D70 swap. Did everything myself except a hand sandblasting here and there from Dad. Took 4 months total:

Before:

After:

This spring's (mostly completed) project. My buddy commissioned me to do for him. He helped to. 1989 Dodge W350 cummins. Was supposed to get just new body panels but we dived in all the way and took it completely apart.

After it 4 hours we had it to this. Before:

Still needs lots of little stuff but is road legal. Bed needs painted. The blue is Ford Norsea Blue Metallic. I sprayed it and it still needs wet sanding and buffing. After:

So yeah, my goal is every spring to do one restoration of a vehicle until I feel satisfied with a collection lol. I also have a 1965 Coronet Sedan that is supposed to be an A990 clone that is completely stripped down and needs floors put in which were already bought. Have fiberglass front fenders already as well as a built D60 4:56 powerlok for it and a 4 speed hemi box ready for a stroker.....

So the Dart will be looked upon as a lesson for the dangers of rust. I plan to treat 100% of the panels no matter how hard it is and then once all treated with acid/epoxy primer/epoxy resin it will be painted and then all passages sprayed with cosmoline. I want to drive it but it will be stored indoors full time this time around and I only want to do it once. No undercoating but the wheel wells will be lined with Monstaliner bedliner. Also will build my own stainless 2.5" exhaust to make the 340HP manifolds work and flow a little better then they currently do with whatever exhaust is in it now. Will install the AC this time and really just do my best on it!

The good thing is at my age, I learned the risks of rust so when I did my truck and my buddies everything was treated well. Should last a long time with proper maintenance. I guess I'm so obsessive about rust it's the reason I washed my truck 3 times over winter and then sprayed the whole underside with WD40! I just like to preserve my efforts.

Charlie

As it was in 1999:

In case you were wondering my dad's common username is pigdoc he is part of the Mopar Mailing List just like me.

From Dr Mopar's salvage, here's the new body:

Has some quarter damage:

Since we got it in 2010, it sat on dollies as we dropped the /6 and took the suspension out. Yesterday, I completely gutted the interior, took windshield and dash out, cleaned up the inside a little and then took the junk hood off and put the good hood on and sandblasted the hinge spots and cold galvanized them and mounted it. Will be sending it to get soda blasted later this month. I'm taking the project on mostly by myself as I think I have enough experience now after doing 2 trucks:

My 1977 M880 with a cummins 5 speed D60/D70 swap. Did everything myself except a hand sandblasting here and there from Dad. Took 4 months total:

Before:

After:

This spring's (mostly completed) project. My buddy commissioned me to do for him. He helped to. 1989 Dodge W350 cummins. Was supposed to get just new body panels but we dived in all the way and took it completely apart.

After it 4 hours we had it to this. Before:

Still needs lots of little stuff but is road legal. Bed needs painted. The blue is Ford Norsea Blue Metallic. I sprayed it and it still needs wet sanding and buffing. After:

So yeah, my goal is every spring to do one restoration of a vehicle until I feel satisfied with a collection lol. I also have a 1965 Coronet Sedan that is supposed to be an A990 clone that is completely stripped down and needs floors put in which were already bought. Have fiberglass front fenders already as well as a built D60 4:56 powerlok for it and a 4 speed hemi box ready for a stroker.....

So the Dart will be looked upon as a lesson for the dangers of rust. I plan to treat 100% of the panels no matter how hard it is and then once all treated with acid/epoxy primer/epoxy resin it will be painted and then all passages sprayed with cosmoline. I want to drive it but it will be stored indoors full time this time around and I only want to do it once. No undercoating but the wheel wells will be lined with Monstaliner bedliner. Also will build my own stainless 2.5" exhaust to make the 340HP manifolds work and flow a little better then they currently do with whatever exhaust is in it now. Will install the AC this time and really just do my best on it!

The good thing is at my age, I learned the risks of rust so when I did my truck and my buddies everything was treated well. Should last a long time with proper maintenance. I guess I'm so obsessive about rust it's the reason I washed my truck 3 times over winter and then sprayed the whole underside with WD40! I just like to preserve my efforts.

Charlie