If you study fluid dynamics, you learn that any sudden expansion or contraction in the flow causes a loss in flow energy.

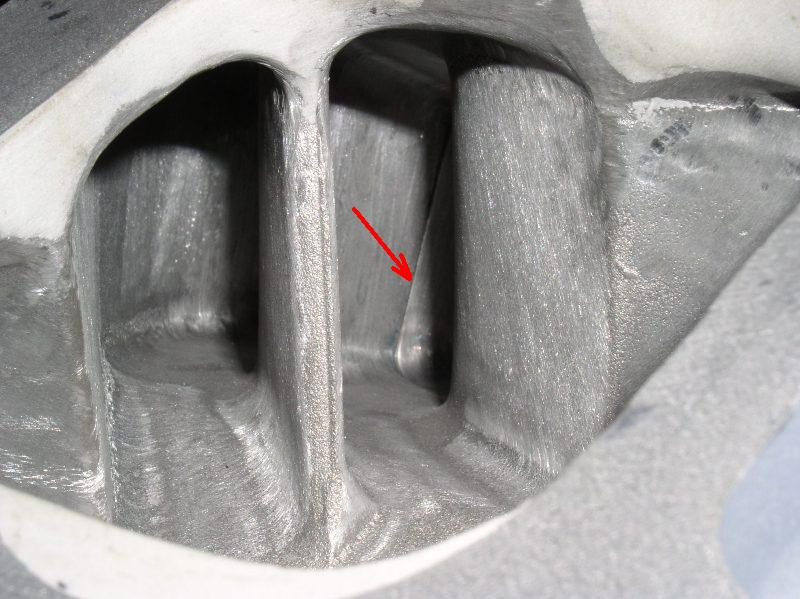

When the intake runner is larger than the head port, then the air runs into the wall and gets "backed up" which will interfere with the flow slowing it down.

If your intake port is smaller than the head port, the sudden increase in area causes the air flow to slow down also.

It's best to match it as good as you can for optimum flow.

VELOCITY = TORQUE when talking about intake flow.

Sure, it's minimal, but we are all trying to squeeze every last horsepower out of our engines that we can....

If you want to waste horsepower, you could always run two A/C compressors.... LOL!