Kicking off yet another week of awesome productivity!

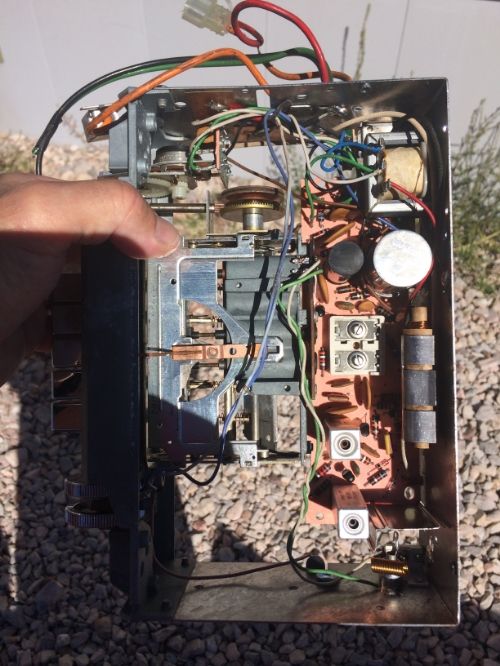

I have, with me, everything I need to finish up some detail work on the dash and instrument panel and plan to have the entire dash reassembled into a singular unit. I also have the cockpit wiring harness so that I'll be able to plug everything in where it belongs and finish wrapping the bundle.

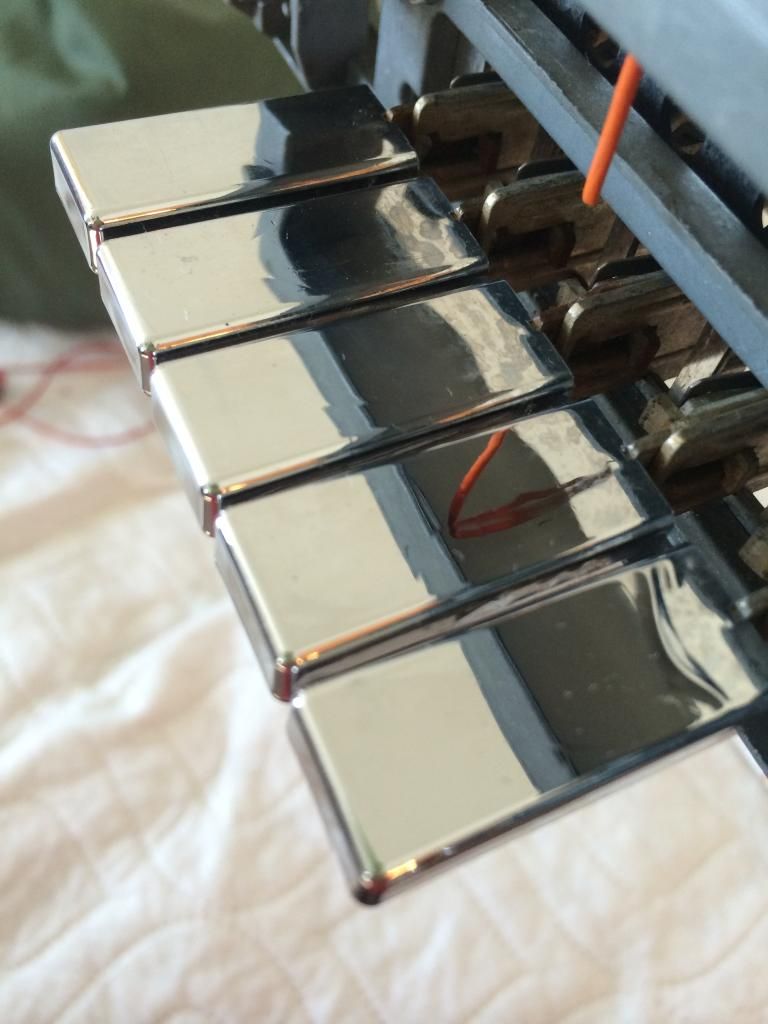

Today, while between calls, I am polishing the frame with a light compound and I'll follow that up with a protective coat of something - probably nu finish. I like that stuff.

I have, with me, everything I need to finish up some detail work on the dash and instrument panel and plan to have the entire dash reassembled into a singular unit. I also have the cockpit wiring harness so that I'll be able to plug everything in where it belongs and finish wrapping the bundle.

Today, while between calls, I am polishing the frame with a light compound and I'll follow that up with a protective coat of something - probably nu finish. I like that stuff.