The Great Pumpkin - '71 Duster

OK, more progress on the engine stuff.

Took the bottom end apart, found that it was definitely worn. The bearings were toast. Looking at the stampings on the back of the bearings said that they were from 1997, some even from 1994. Obviously this engine had been together for a long time so none of this is a surprise. All in all though, the engine had no major damage or anything.

It appears there may have been debris in there at some point because the mains were down to the copper. Mostly on the top though which was odd. I bet that those valve stem seal clips were what ended up embedded in the bearings because they weren't in the oil pump pickup. Doh!

The rod bearings also had uneven wear. The top halves were worn to the copper but the bottoms appeared OK. It was suggested to me that the engine was detonating causing the wear on the rod and main bearing upper halves. The detonation would have caused the piston and rod to be forced down on to the rod journal so that partially explains it. I was thinking that something may have been a little bent too because the bearings looked better closer to the front. The crank visually appeared OK though so all this is only a guess.

I also thought that contaminated oil could have done some of the damage. Last spring when I replaced the old MP orange box with an MSD 6, I had some starting issues because of a crossed wire. A lot of unburned fuel wound up going down into the cylinders which would explain that. I never drove it with the oil like that but I figure that all the aborted starting attempts was a contributor.

I will mention also that I sold the entire rotating assembly this week to a guy on Moparts. He was looking for the exact pistons I had. I got in touch with him and offered them and then he asked to buy the entire reciprocating assembly. We came to a deal and off it went. Kind of a weird feeling since just a month ago these parts were running but I was glad I did it, less stuff to sit around and trip over. The crank and rods were .010" under already which he knew. I believe those parts were at the end of their service, any further use on them is gravy.

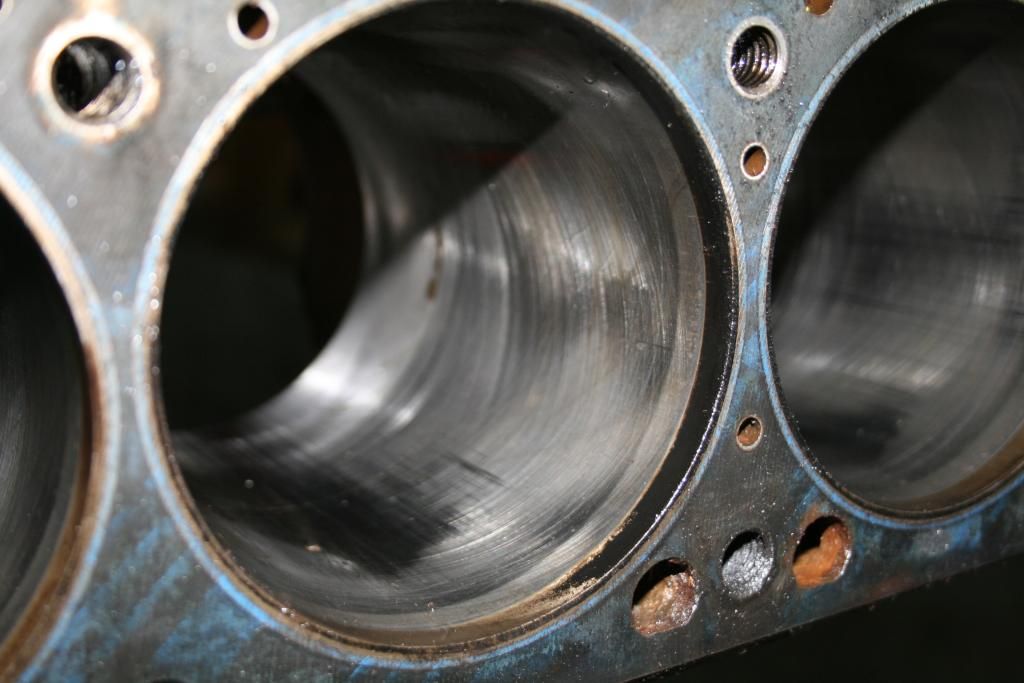

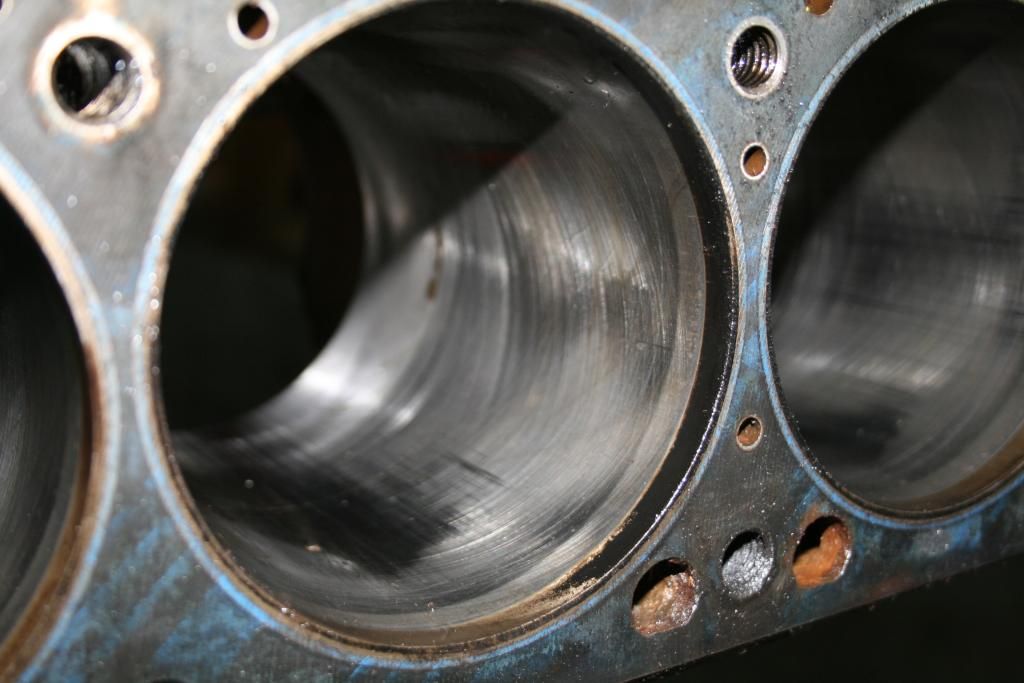

So the block itself is .030" over and to my untrained eye it looks to have to some uneven wear in the bores. Not sure what this could be due to, maybe piston rock. I doubt it will clean up with a light hone so it would have to be sonic checked before moving forward. I fumbled around with my cheapo dial bore gage trying to get an idea on how it reads but it wasn't working for me too well. In any event, I have two other 340 blocks on hand, one of which is standard bore but will need to be checked to make sure it's usable. Hope that one is good, not real interested in any more boat anchors. Gonna take one of the blocks down to the machine shop soon to get it looked at.

In the meantime, I sent a pair of RHS heads to Brian @ IMM. I spoke with him recently and he suggested having them sent out to be CNC ported with his program along with installing appropriate valves and springs. Gonna discuss the rest of the build with him sometime this week, hope to make decisions on parts soon. Thinking a roll bar might be in my immediate future.

There are a few other things I am going to try and take care of while the engine is out. I need to re-weld the spring perches on the rear end to achieve the proper pinion angle. I had 4 degree shims in there to correct it before but it was never great, had a vibration on decel from higher speeds. I also noticed a leak from the R/R wheel cylinder so that has to be addressed while the rear is apart.

The fuel system also needs some help. I pretty much decided on an electric pump. Found a Mallory 140 on Ebay through JC Whitney for a ridiculously low price. Bought it and they cancelled the auction due to 'no stock'. Not happy. Guess the realized their mistake and didn't feel like giving away a $400 pump for under $90. Still looking around at options for now. I like the idea of an in-tank pump. They are the quietest and keep the pump off the chassis. Thinking about the Aeromotive Stealth system, seems like a good option for a street/strip application.

I will probably be taking the trans out for a freshen up too. It was fine but considering how old everything else is, it's probably time for a rebuild. When I was a tech, the last job I had was doing all powertrain. I'll probably take it back to my old shop and do it there.

Hope to get back to this stuff in the coming weeks. It's been very cold here, have not been out in the garage much. Might have to get a heater of some sort.

On to the pics.

Main bearings.

Rod bearings.

Here's one of the crank journals. Fuzzy stuff is rag material.

Shot of a cylinder.

Here's pistons and rods. Skirts looked good actually.

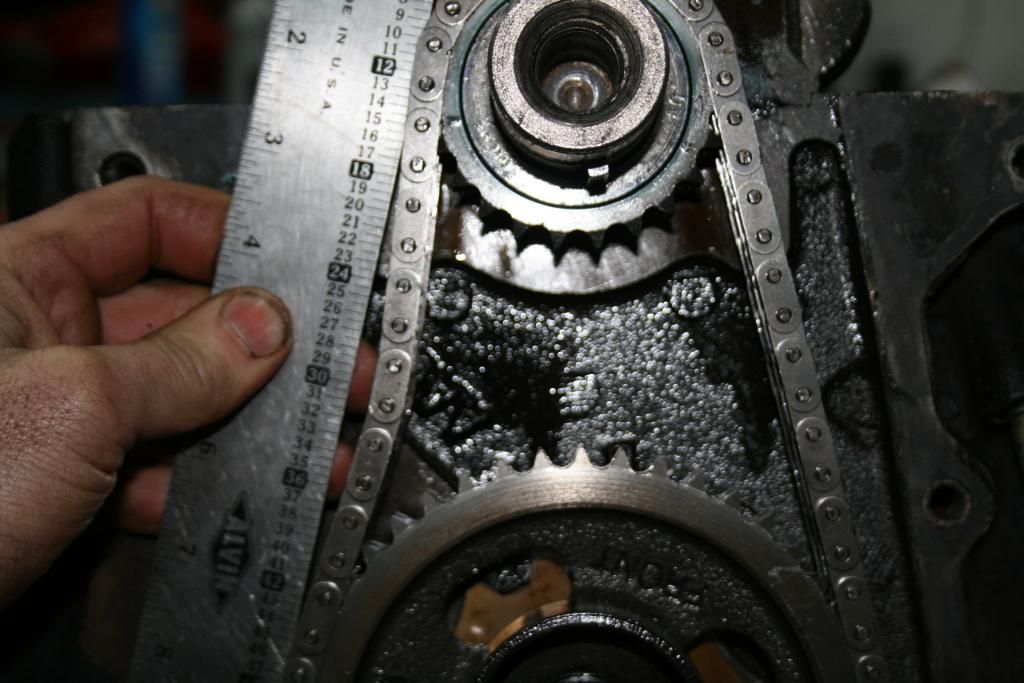

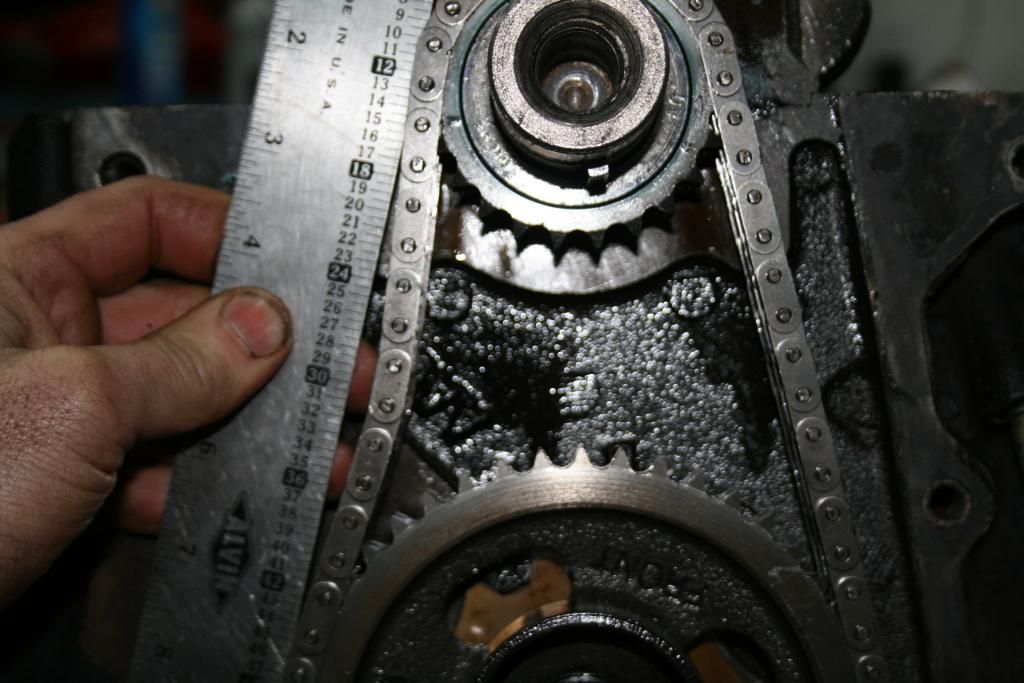

Here's the timing chain, which I thought had too much slack. Felt looser than what the pic shows.

That's all for now. More to come.

OK, more progress on the engine stuff.

Took the bottom end apart, found that it was definitely worn. The bearings were toast. Looking at the stampings on the back of the bearings said that they were from 1997, some even from 1994. Obviously this engine had been together for a long time so none of this is a surprise. All in all though, the engine had no major damage or anything.

It appears there may have been debris in there at some point because the mains were down to the copper. Mostly on the top though which was odd. I bet that those valve stem seal clips were what ended up embedded in the bearings because they weren't in the oil pump pickup. Doh!

The rod bearings also had uneven wear. The top halves were worn to the copper but the bottoms appeared OK. It was suggested to me that the engine was detonating causing the wear on the rod and main bearing upper halves. The detonation would have caused the piston and rod to be forced down on to the rod journal so that partially explains it. I was thinking that something may have been a little bent too because the bearings looked better closer to the front. The crank visually appeared OK though so all this is only a guess.

I also thought that contaminated oil could have done some of the damage. Last spring when I replaced the old MP orange box with an MSD 6, I had some starting issues because of a crossed wire. A lot of unburned fuel wound up going down into the cylinders which would explain that. I never drove it with the oil like that but I figure that all the aborted starting attempts was a contributor.

I will mention also that I sold the entire rotating assembly this week to a guy on Moparts. He was looking for the exact pistons I had. I got in touch with him and offered them and then he asked to buy the entire reciprocating assembly. We came to a deal and off it went. Kind of a weird feeling since just a month ago these parts were running but I was glad I did it, less stuff to sit around and trip over. The crank and rods were .010" under already which he knew. I believe those parts were at the end of their service, any further use on them is gravy.

So the block itself is .030" over and to my untrained eye it looks to have to some uneven wear in the bores. Not sure what this could be due to, maybe piston rock. I doubt it will clean up with a light hone so it would have to be sonic checked before moving forward. I fumbled around with my cheapo dial bore gage trying to get an idea on how it reads but it wasn't working for me too well. In any event, I have two other 340 blocks on hand, one of which is standard bore but will need to be checked to make sure it's usable. Hope that one is good, not real interested in any more boat anchors. Gonna take one of the blocks down to the machine shop soon to get it looked at.

In the meantime, I sent a pair of RHS heads to Brian @ IMM. I spoke with him recently and he suggested having them sent out to be CNC ported with his program along with installing appropriate valves and springs. Gonna discuss the rest of the build with him sometime this week, hope to make decisions on parts soon. Thinking a roll bar might be in my immediate future.

There are a few other things I am going to try and take care of while the engine is out. I need to re-weld the spring perches on the rear end to achieve the proper pinion angle. I had 4 degree shims in there to correct it before but it was never great, had a vibration on decel from higher speeds. I also noticed a leak from the R/R wheel cylinder so that has to be addressed while the rear is apart.

The fuel system also needs some help. I pretty much decided on an electric pump. Found a Mallory 140 on Ebay through JC Whitney for a ridiculously low price. Bought it and they cancelled the auction due to 'no stock'. Not happy. Guess the realized their mistake and didn't feel like giving away a $400 pump for under $90. Still looking around at options for now. I like the idea of an in-tank pump. They are the quietest and keep the pump off the chassis. Thinking about the Aeromotive Stealth system, seems like a good option for a street/strip application.

I will probably be taking the trans out for a freshen up too. It was fine but considering how old everything else is, it's probably time for a rebuild. When I was a tech, the last job I had was doing all powertrain. I'll probably take it back to my old shop and do it there.

Hope to get back to this stuff in the coming weeks. It's been very cold here, have not been out in the garage much. Might have to get a heater of some sort.

On to the pics.

Main bearings.

Rod bearings.

Here's one of the crank journals. Fuzzy stuff is rag material.

Shot of a cylinder.

Here's pistons and rods. Skirts looked good actually.

Here's the timing chain, which I thought had too much slack. Felt looser than what the pic shows.

That's all for now. More to come.