bw68d100318

Member

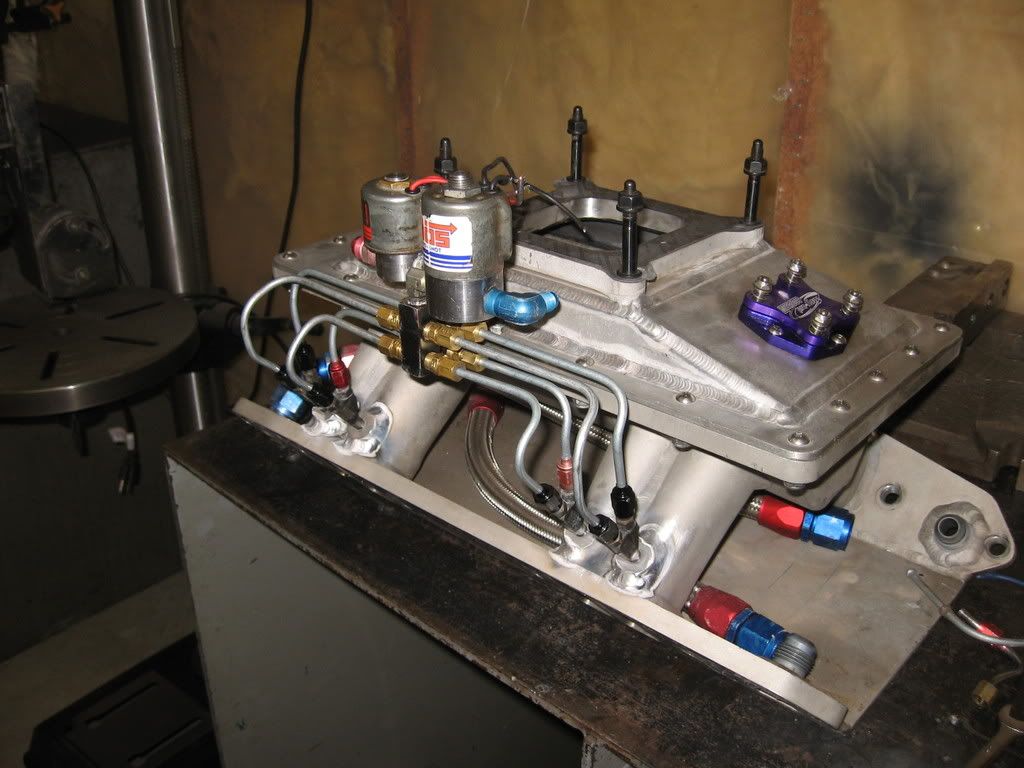

Has anyone just fabricated homemade heads? I'm brainstorming about homemade/fabricated heads and fabricated intake. The amount of time spent on "factory" castings to port/ polish etc, seems like you could get a good start on just making some. If I have seats installed, milled flat, and bronze bushings installed, what would be the difference if it were in factory cast iron, or fabricated with mild steel? Am i completely crazy for even considering this?