1970 Swinger 340 Hemi Orange 4 speed

Thanks Joel! Good eye, I still have to remove that bracket and weld it to my car (I am keeping all my old metal) I do have the t bracket as well. Wow! That car is looking great! Where did you get that car from? I bet it had a hard life like mine if it's from Canada. The work looks top notch!

It's looking good! You've got your work cutout for you, but if you do it one piece at a time it'll come together... It's only metal. I have not received any pics from my email yet? You should start up a resto thread on here once you get started, I'd like to see your progress.

I got my sheet metal from Lee Robinson (that's his username on here as well) from California. He parts a lot of cars and is a great guy to deal with, he went above and beyond helping me get the clip up here. I'm sure if you PM him on here he'll have a lot of the metal you're looking for, and if not I'm sure he'll get another car to part out.

Thanks! Haha I'm sure it could.. That pile is starting to consume a good part of my garage. I see your car is coming along great!!

The pinion snubber area has been quite a battle but it's almost completed. I couldn't get all the brass out since I don't have an oxyacetylene torch so I butt welded in a piece that I removed from my parts car. It is now nice and solid, so tomorrow I'll weld in the floor support, cross braces and all metal my butt weld seams and it'll be ready for epoxy.

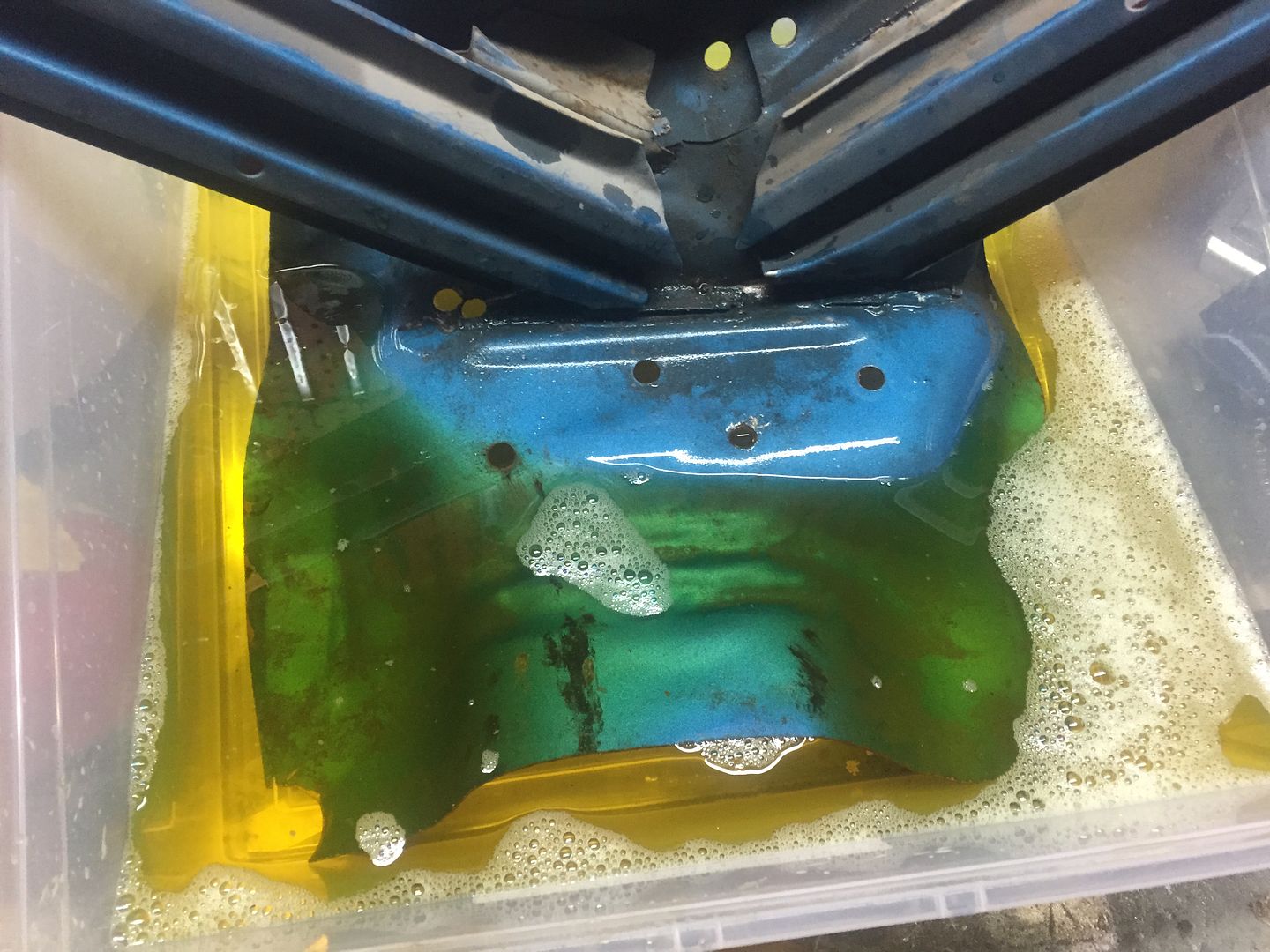

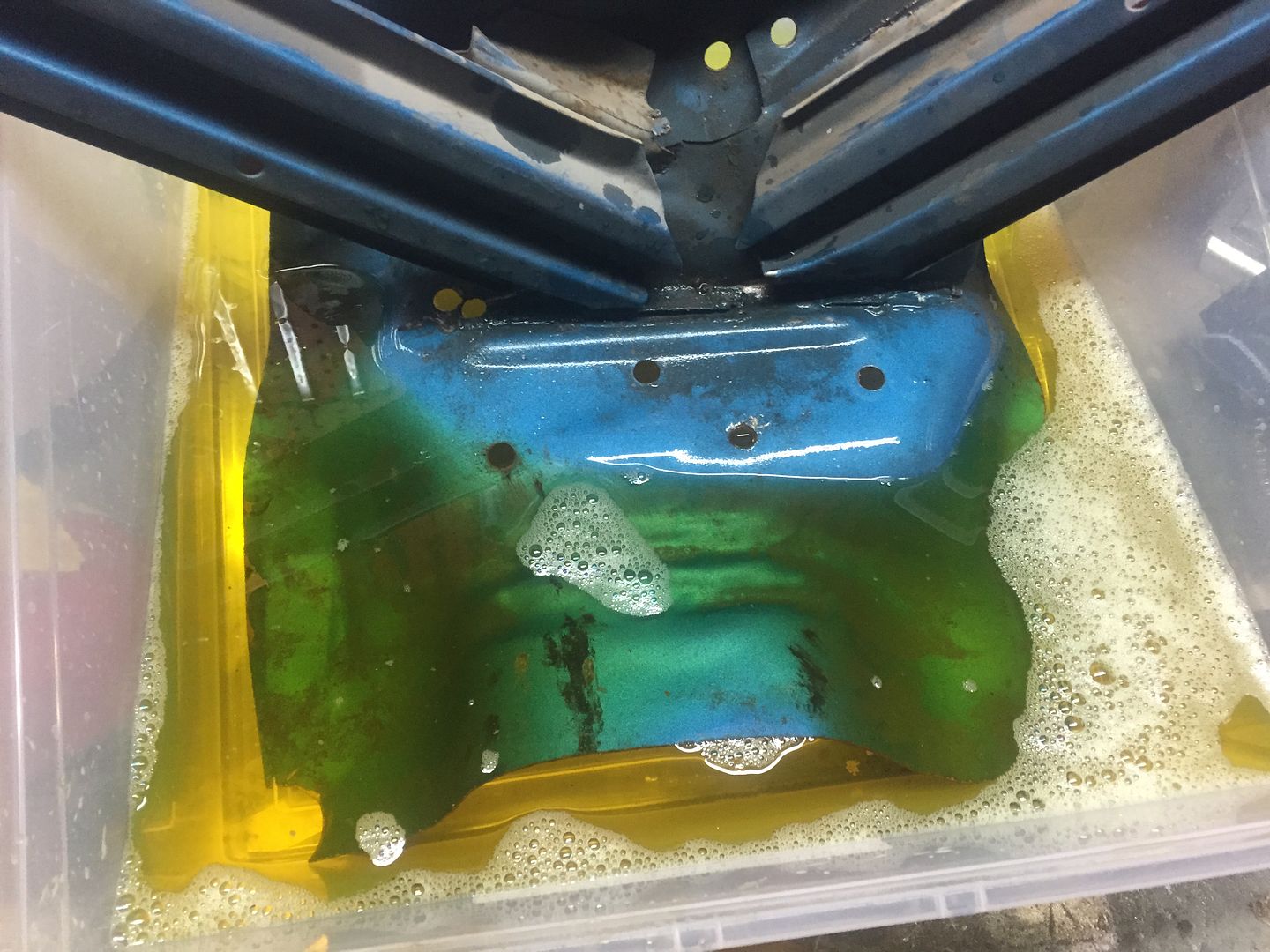

Soaked in evaporust since the bottom was rusty.

Sectioned in piece.

All welded in. Left some profile on the top side of my welds to ensure that the strength was still there.

Support fits perfect.

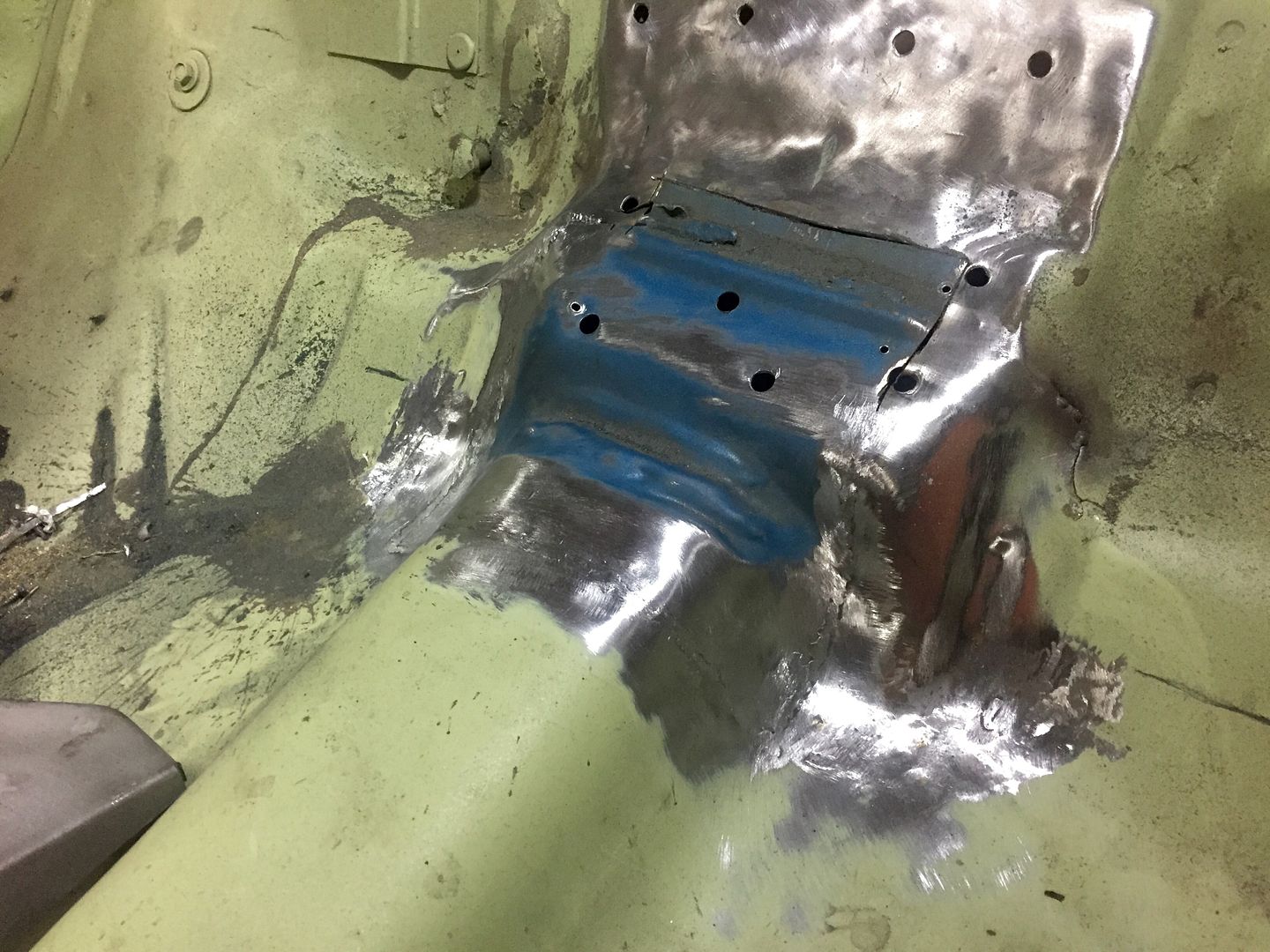

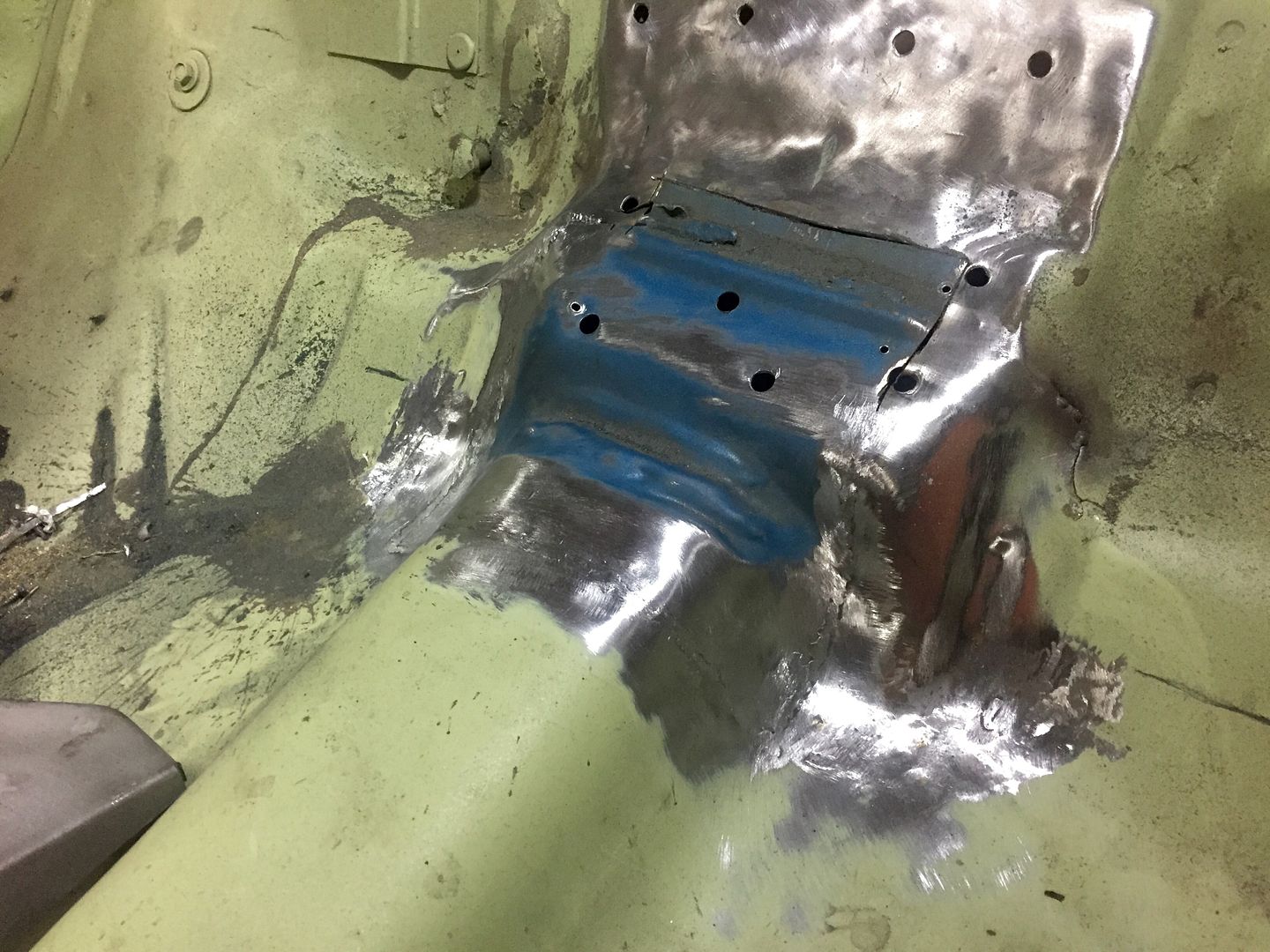

All ground down and new pinion snubber mount welded in.

Thanks Joel! Good eye, I still have to remove that bracket and weld it to my car (I am keeping all my old metal) I do have the t bracket as well. Wow! That car is looking great! Where did you get that car from? I bet it had a hard life like mine if it's from Canada. The work looks top notch!

It's looking good! You've got your work cutout for you, but if you do it one piece at a time it'll come together... It's only metal. I have not received any pics from my email yet? You should start up a resto thread on here once you get started, I'd like to see your progress.

I got my sheet metal from Lee Robinson (that's his username on here as well) from California. He parts a lot of cars and is a great guy to deal with, he went above and beyond helping me get the clip up here. I'm sure if you PM him on here he'll have a lot of the metal you're looking for, and if not I'm sure he'll get another car to part out.

Thanks! Haha I'm sure it could.. That pile is starting to consume a good part of my garage. I see your car is coming along great!!

The pinion snubber area has been quite a battle but it's almost completed. I couldn't get all the brass out since I don't have an oxyacetylene torch so I butt welded in a piece that I removed from my parts car. It is now nice and solid, so tomorrow I'll weld in the floor support, cross braces and all metal my butt weld seams and it'll be ready for epoxy.

Soaked in evaporust since the bottom was rusty.

Sectioned in piece.

All welded in. Left some profile on the top side of my welds to ensure that the strength was still there.

Support fits perfect.

All ground down and new pinion snubber mount welded in.