MS3 Pro Sequential Injection + Coil near plug conversion thread

Well I was hard at work on this project all weekend.

I installed the gas tank friday night but found that the filler neck opening in the tank was made 1/2" further forward than it should be even though this is supposedly a spectra "premium" tank, it's not a china one. This makes the filler neck not fit quite right at the body, and the floor gasket doesn't seal around the neck itself. Since I cannot return since it's modded, I'll have to see what it will take to make it work.

First thing I had to do before wiring was make a bracket for my GM style MAP sensor. This is the older style from the 1980s/1990s that's super common. I used the regular one bar since there's no forced induction here. Just some steel bar welded together. It mounts on the passenger side fuel rail between the rail and the intake runners. Almost invisible when installed!

I really got going on the wiring after that. It's pretty simple actually as the wiring harness that comes with the computer is marked on the wire. For the coils and injectors, they are "lettered" and you just arrange the letters in the firing order. Since we are 1-8-4-3-6-5-7-2, you just do A-H-D-C-F-E-G-B. The injectors need a 12V keyed power feed to the other side which you hook to the fuel relay (mine is fused separately with a 15A on the injectors and a 30 on the fuel pump with the Aeromotive Stealth 340 pump) . The coils need a 12V switched which I hooked to the standard ignition fuse that already existed in the car (I didn't have a ballast resistor, but if you did, you'd have to remove it and jumper them together), a ground (one on each bank if you used the factory 7 pin connector), a sensor return to the computer, and the control wires mentioned above). The wiring isn't too difficult, just tedious. You will need to be good at reading wiring diagrams, soldering and have some good crimping tools, heat shrink, and a good heat gun.

During:

I managed to get all the wiring hooked up other than the VSS IN coming off my speedometer so I can get a speed in the computer/datalogs, and the fuel pump wiring itself. Here's it done, but not loomed (will do that eventually once I make sure I have all the bugs worked out)

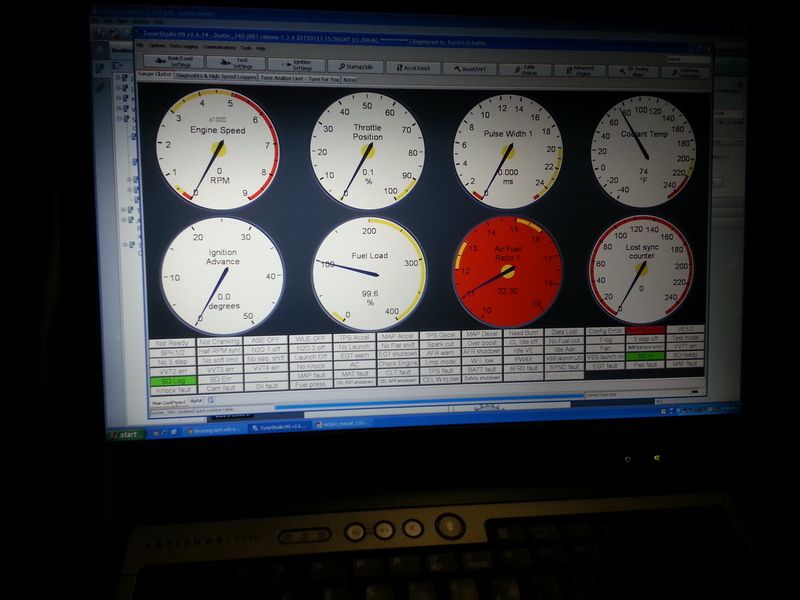

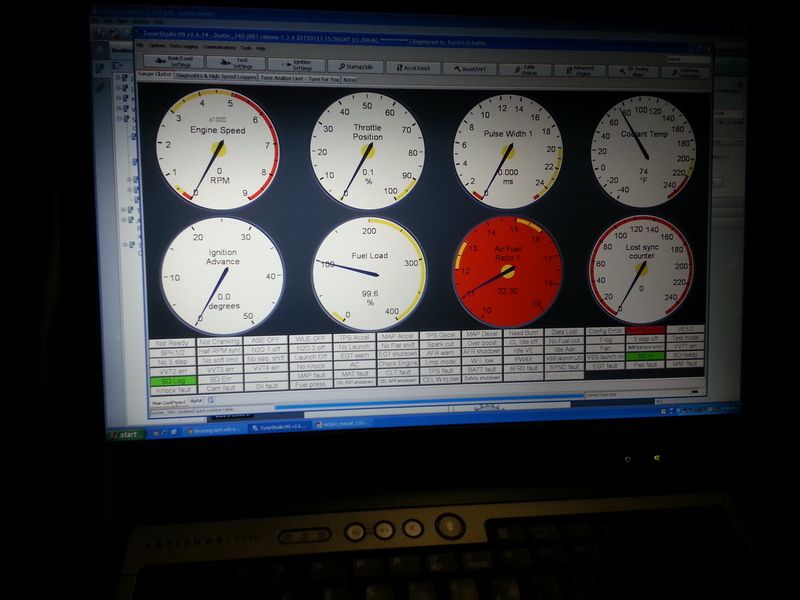

So with only that disconnected, I installed the ECU fuse and powered it up. I was able to connect to the ECU using my old Dell Latitude D830 Laptop (It has a serial port and USB but since that computer has a serial port I used it), and I programmed in my wideband (changed setting to get correct output), calibrated the tps, loaded the sensor calibration for the coolant temp, intake air temp, and MAP sensor, and was able to read all of those.

So, now, I need to get all the data for my crank and cam sync, finish the wiring, button a few things up in the car, and then get into all the test modes to make sure I wired it correctly and that I am getting signals correctly. If that's the case, I can flush out the fuel system, connect it, check for leaks, and then maybe give it a shot to see if she'll run.

I've probably worked on this thing for about 60 hours so far. Not going to be a super fast install if you're trying this at home. And that's AFTER I pre-built a few things.

Well I was hard at work on this project all weekend.

I installed the gas tank friday night but found that the filler neck opening in the tank was made 1/2" further forward than it should be even though this is supposedly a spectra "premium" tank, it's not a china one. This makes the filler neck not fit quite right at the body, and the floor gasket doesn't seal around the neck itself. Since I cannot return since it's modded, I'll have to see what it will take to make it work.

First thing I had to do before wiring was make a bracket for my GM style MAP sensor. This is the older style from the 1980s/1990s that's super common. I used the regular one bar since there's no forced induction here. Just some steel bar welded together. It mounts on the passenger side fuel rail between the rail and the intake runners. Almost invisible when installed!

I really got going on the wiring after that. It's pretty simple actually as the wiring harness that comes with the computer is marked on the wire. For the coils and injectors, they are "lettered" and you just arrange the letters in the firing order. Since we are 1-8-4-3-6-5-7-2, you just do A-H-D-C-F-E-G-B. The injectors need a 12V keyed power feed to the other side which you hook to the fuel relay (mine is fused separately with a 15A on the injectors and a 30 on the fuel pump with the Aeromotive Stealth 340 pump) . The coils need a 12V switched which I hooked to the standard ignition fuse that already existed in the car (I didn't have a ballast resistor, but if you did, you'd have to remove it and jumper them together), a ground (one on each bank if you used the factory 7 pin connector), a sensor return to the computer, and the control wires mentioned above). The wiring isn't too difficult, just tedious. You will need to be good at reading wiring diagrams, soldering and have some good crimping tools, heat shrink, and a good heat gun.

During:

I managed to get all the wiring hooked up other than the VSS IN coming off my speedometer so I can get a speed in the computer/datalogs, and the fuel pump wiring itself. Here's it done, but not loomed (will do that eventually once I make sure I have all the bugs worked out)

So with only that disconnected, I installed the ECU fuse and powered it up. I was able to connect to the ECU using my old Dell Latitude D830 Laptop (It has a serial port and USB but since that computer has a serial port I used it), and I programmed in my wideband (changed setting to get correct output), calibrated the tps, loaded the sensor calibration for the coolant temp, intake air temp, and MAP sensor, and was able to read all of those.

So, now, I need to get all the data for my crank and cam sync, finish the wiring, button a few things up in the car, and then get into all the test modes to make sure I wired it correctly and that I am getting signals correctly. If that's the case, I can flush out the fuel system, connect it, check for leaks, and then maybe give it a shot to see if she'll run.

I've probably worked on this thing for about 60 hours so far. Not going to be a super fast install if you're trying this at home. And that's AFTER I pre-built a few things.