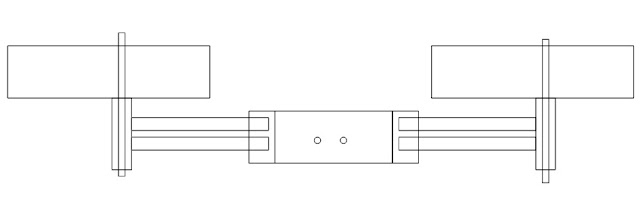

As the temperature start getting colder I am reminded I never finished the install of my new heater box. I got the heater box from Summit Racing and had previously fabbed up some tubes to mount the box. Having the retractable tubes has two advantages: 1) easy installation where you slide the small tubes in and then set the unit so the bolts go through the firewall and then angle it up into position and slide the smaller tubs out to rest on the inside shelf of the dash. 2) in a bad accident the tubes can collapse and prevent spearing the passenger.

The big end has a bolt with the head welded inside the tube. The bolts go through the firewall and are retained by a washer and nut. As it turned out, one bolt came through the firewall behind the distributor and the other came through just inside the wheel housing. One of the things I needed to do was paint the raw metal. I ended up painting it with a dark hammer tone paint.

OK, the paint is dry and now I need to figure out how to direct the ducts on the heater box to the right places. My Dart has two defroster vents in the dash that I wanted to have connected to the heater box. The factory tubing is too small to connect to the opening on the heater box. The solution was to pick up some reducer, 90 degree, elbows to connect the factory tubing to the heater box.

http://intakehoses.com/ I also picked up a non-reducer, 90 degree elbow to direct the third vent down at the passengers feet. (my wife always complains her feet are cold.)

The factory tubing fit tightly inside the smaller end of the reducer elbows. I had to do some trimming to the elbows to reduce their length to get a nice fit under the dash.

I had to use heater hose inside the car to connect the heater box to the custom bulkhead fittings I bought from a hotrod shop. Once the heater box was mounted inside the car, I laid out the hose routing under the hood. I am not a big fan of heater hoses running all over under the hood. The placement of the bulkhead fitting gave me a pretty straight shot just inside the passenger valve cover.

Now it was time to hook the hoses up and check for leaks.

I didn't find any leaks, so now all I have left is the wiring.