I intend to have a simple audio system on board when it's all said and done. Part of this system will include an amplifier mounted in the trunk and I will need a means by which to toggle the amp on and off.

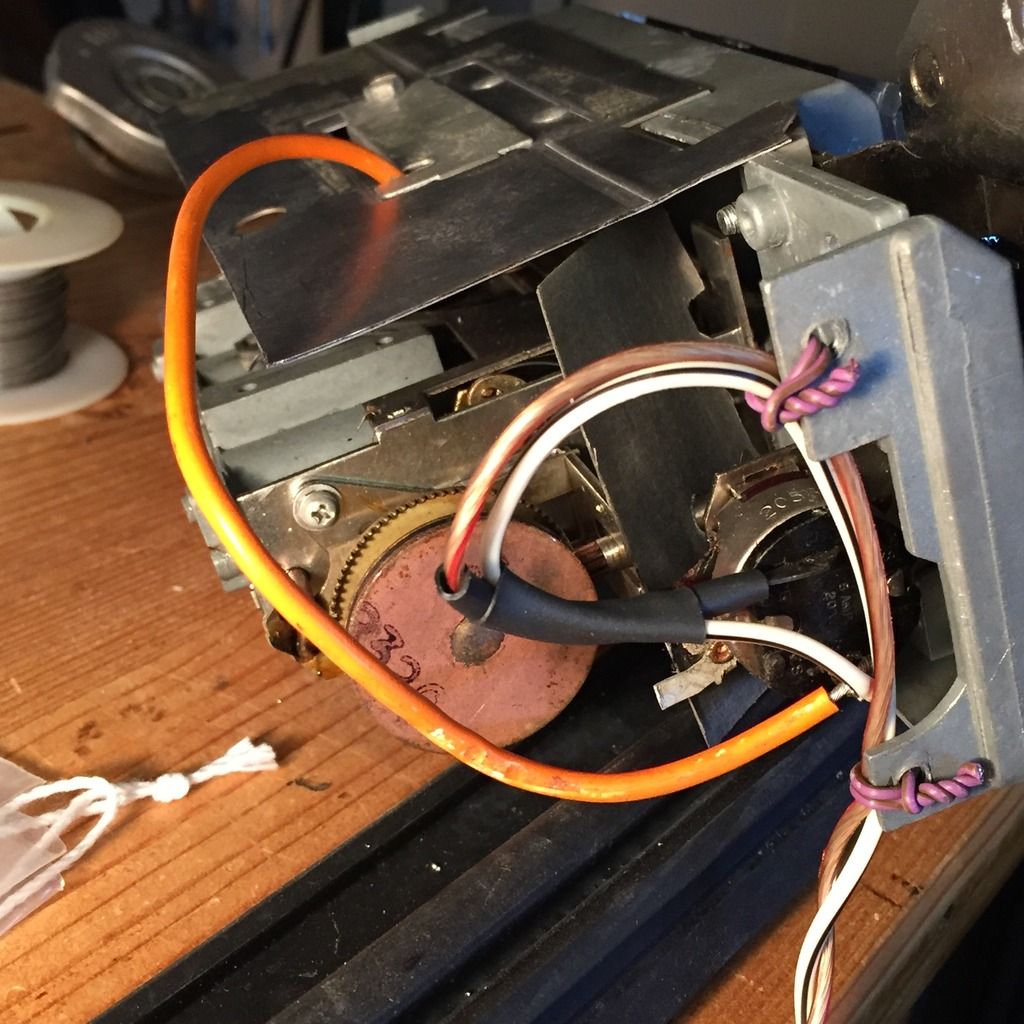

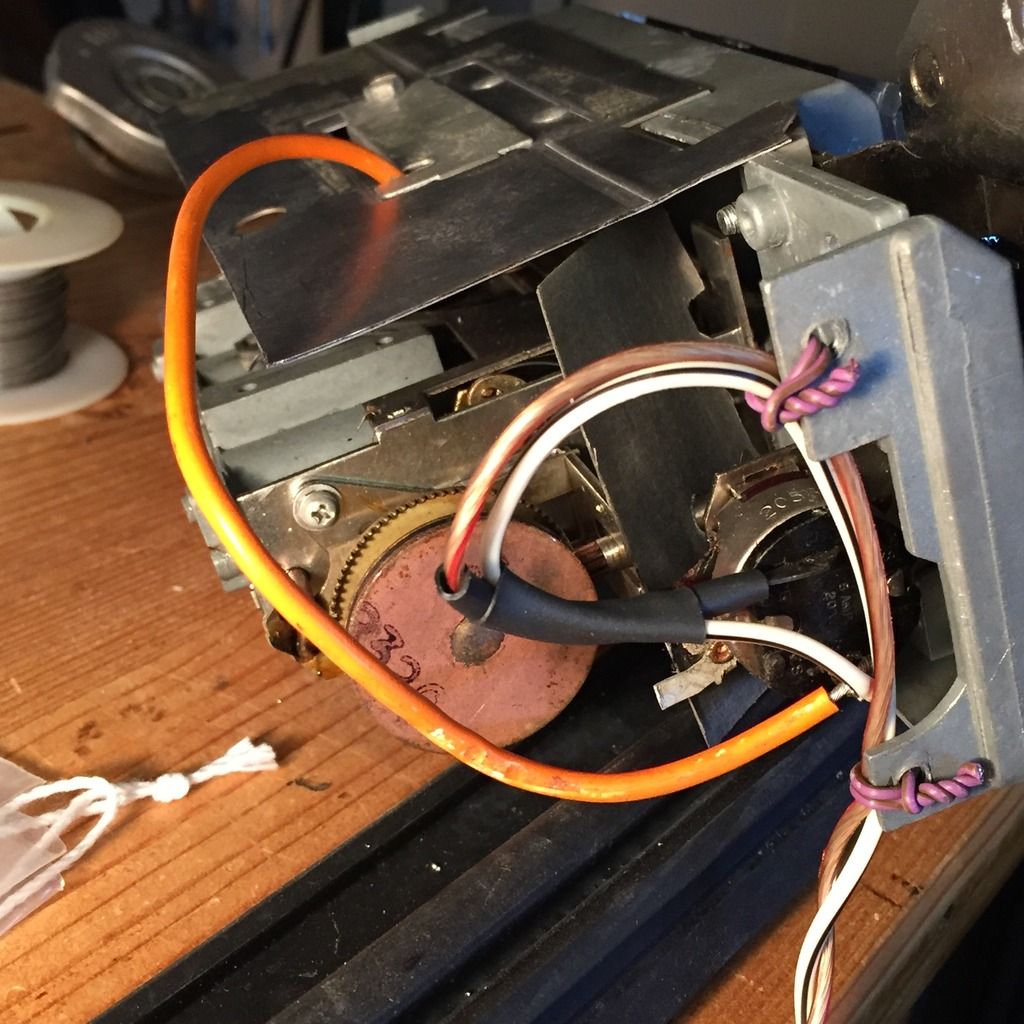

My plan is to use the AM radio's ON/OFF switch. It only took a few minutes with the multimeter to figure out which contacts to wire into for this.

When you switch the radio on, it will energize the remote ON lead to the amp and also illuminate the tuning window.

[ame="https://www.youtube.com/watch?v=Cz_2GMHZS0Y"]https://www.youtube.com/watch?v=Cz_2GMHZS0Y[/ame]

My plan is to use the AM radio's ON/OFF switch. It only took a few minutes with the multimeter to figure out which contacts to wire into for this.

When you switch the radio on, it will energize the remote ON lead to the amp and also illuminate the tuning window.

[ame="https://www.youtube.com/watch?v=Cz_2GMHZS0Y"]https://www.youtube.com/watch?v=Cz_2GMHZS0Y[/ame]