Resurrecting the 1966 Dart Wagon

So new year, new me right? :toothy1:

2015 was filled with working on OTHER peoples vehicles. Fun but.... shop still has space taken up with a 65 coronet 2 dr post and the dart wagons which we just haven't had time to work on. Thing is, you HAVE to dedicate yourself to MAKING TIME!

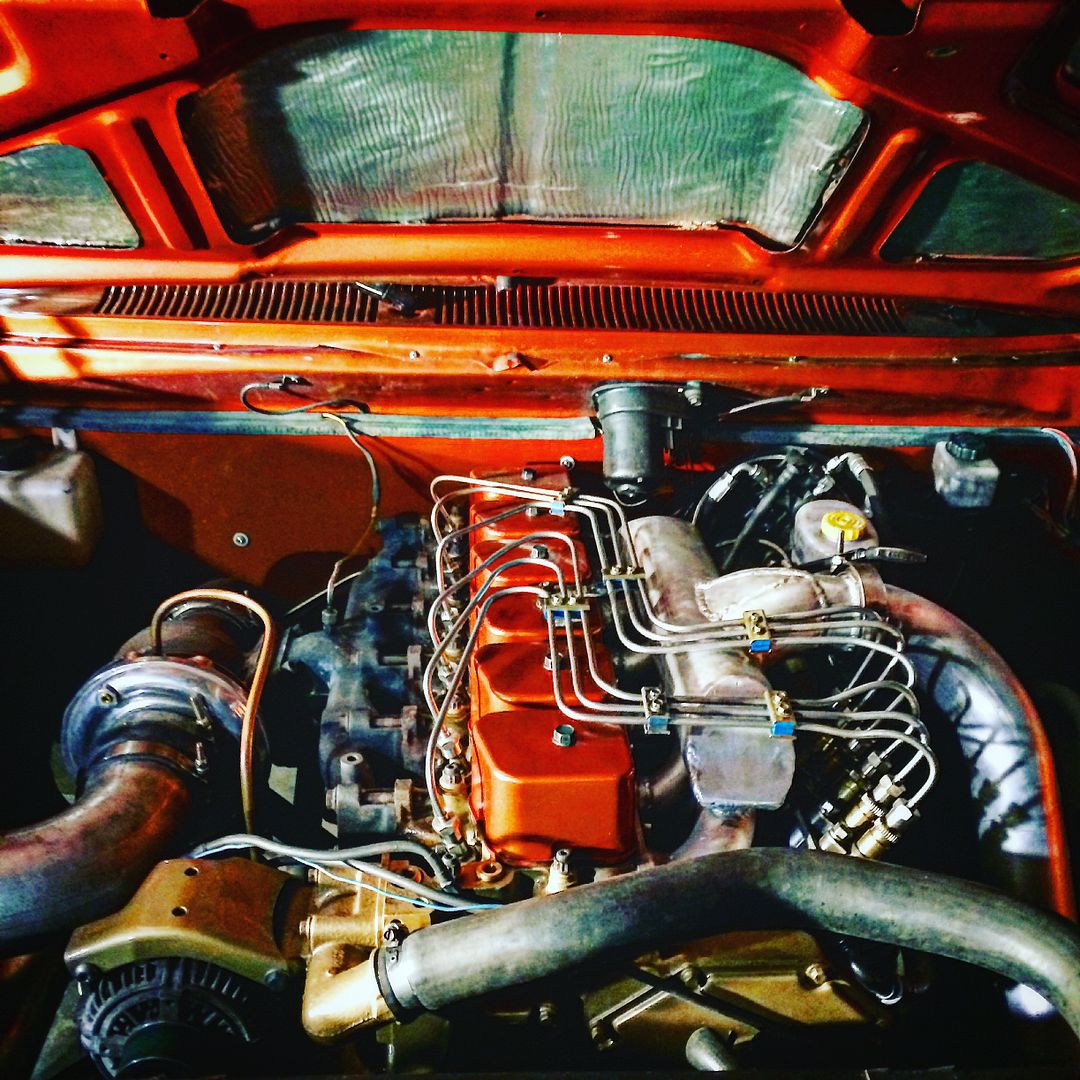

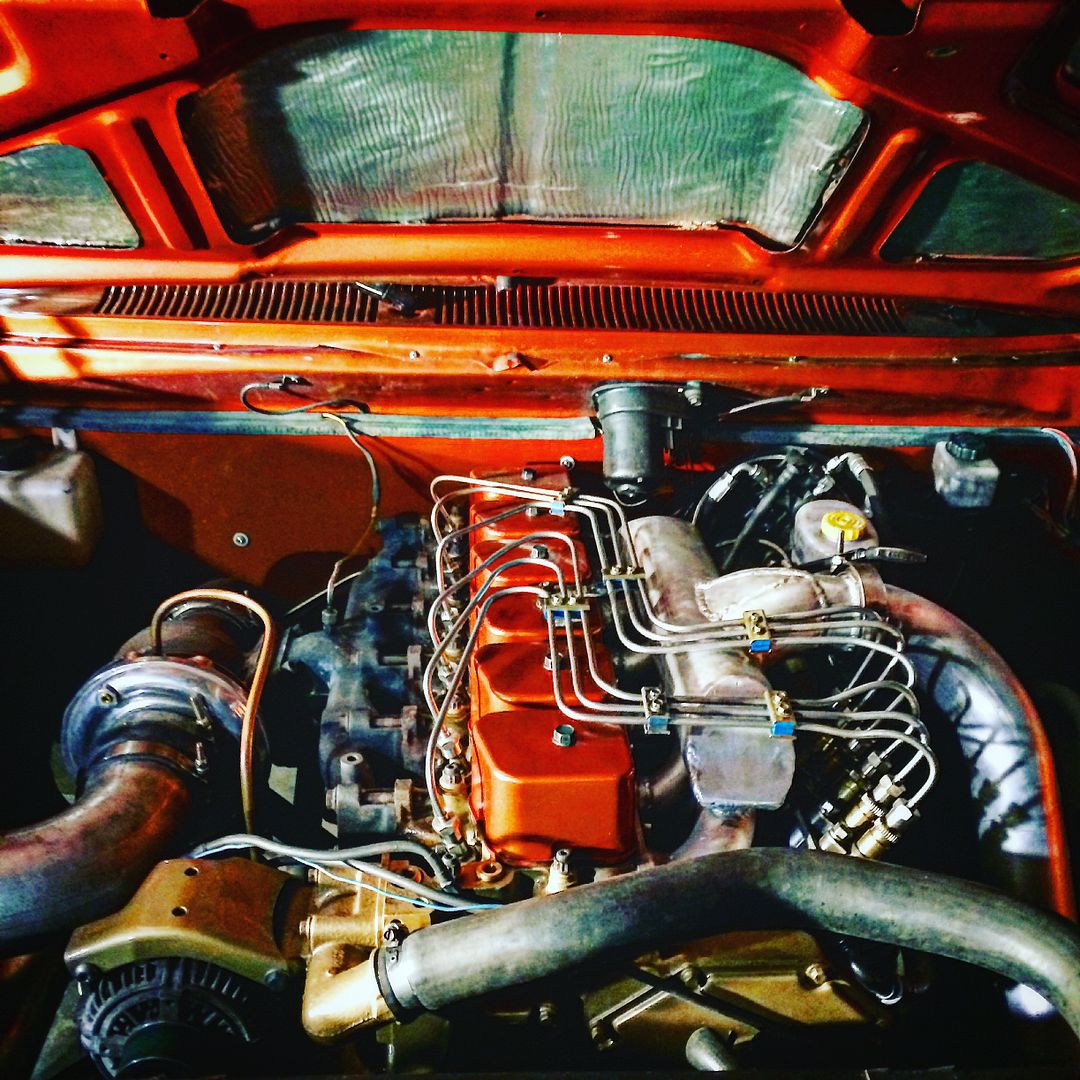

Off topic but in the time since this post was updated, I finished these two trucks. Blue one is an 85 crew from OK for my cousin we did a cummins swap and various other improvements on. Orange is mine after a second engine rebuild and my own 3 link coilover suspension design. My new engine made 512hp 1008ft lbs to the rear wheels and I'm planning to do twin turbos on it this spring. SO, while it is sleeping for winter, time to focus on Dart and 2 customer vehicles:

Engine I built myself and included doing the following: Flycutting pistons, sending them for ceramic coating, sending block and crank out for machining, port/polishing the head, decking and o-ringing the head, building my own custom aluminum runner intake, doing my own injector lines etc etc etc.

PSSSTTTT that is 65 Gold Interior color :glasses7:

Everything you see now has happened in the last TWO weeks. I was getting rather pissy seeing a pristene bare metal body starting to flash rust so I figured I better get on the project and get it f"""ing done before something takes priority over it and while I have so much free time being single. I recently rebuilt and installed a 300k BTU clean burn waste oil heater which keeps the shop at 70* and is great to work in when it's 12* outside

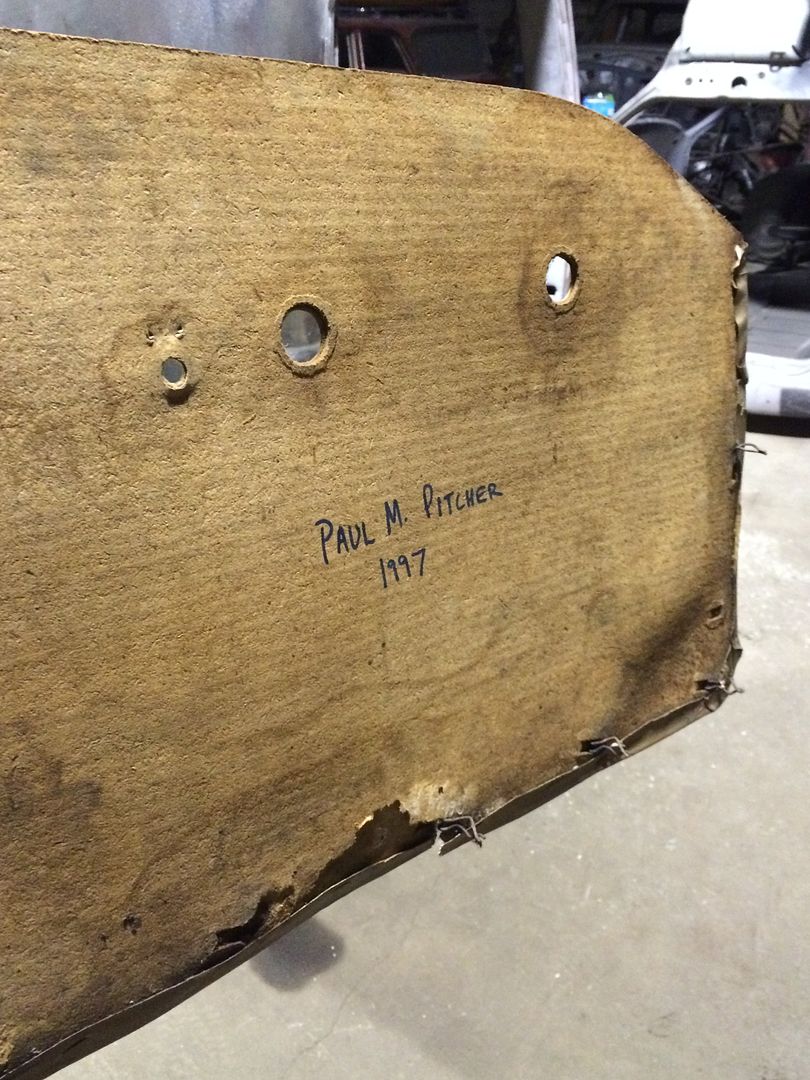

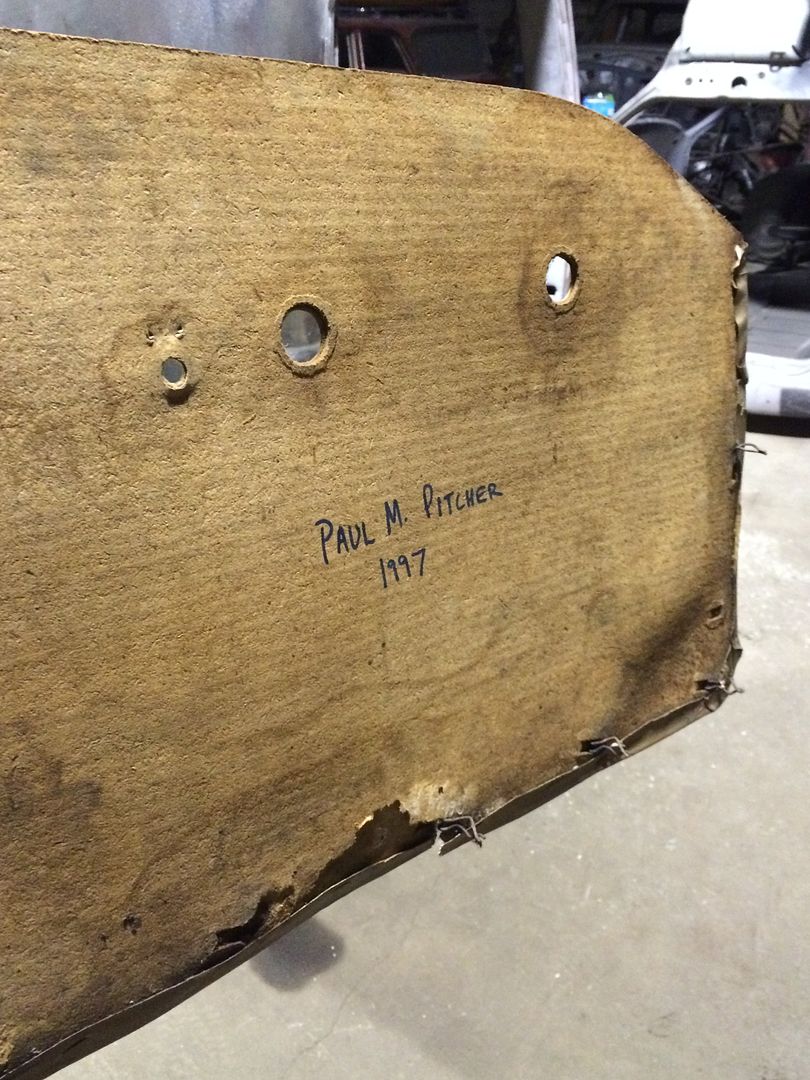

Dad's marking:

The mess! 360 magnum/A500 big bolt disc brakes!

Test Fit! Filling any holes not needed on firewall and inner fenders and was very happy to see the trans tunnel I made fits like a glove to the trans!

Entire old body is disassembled, bagged and tagged and various documentation points done. Started going through the NOS stash and picking the best parts out. Nice to find things I thought I needed and finding them in the inventory! Next is finish my custom trans mount, weld cowl back on and quarter patch and tear it back down for all chassis parts to be powder coated, trans freshened, engine freshened and epoxy on body!

So new year, new me right? :toothy1:

2015 was filled with working on OTHER peoples vehicles. Fun but.... shop still has space taken up with a 65 coronet 2 dr post and the dart wagons which we just haven't had time to work on. Thing is, you HAVE to dedicate yourself to MAKING TIME!

Off topic but in the time since this post was updated, I finished these two trucks. Blue one is an 85 crew from OK for my cousin we did a cummins swap and various other improvements on. Orange is mine after a second engine rebuild and my own 3 link coilover suspension design. My new engine made 512hp 1008ft lbs to the rear wheels and I'm planning to do twin turbos on it this spring. SO, while it is sleeping for winter, time to focus on Dart and 2 customer vehicles:

Engine I built myself and included doing the following: Flycutting pistons, sending them for ceramic coating, sending block and crank out for machining, port/polishing the head, decking and o-ringing the head, building my own custom aluminum runner intake, doing my own injector lines etc etc etc.

PSSSTTTT that is 65 Gold Interior color :glasses7:

Everything you see now has happened in the last TWO weeks. I was getting rather pissy seeing a pristene bare metal body starting to flash rust so I figured I better get on the project and get it f"""ing done before something takes priority over it and while I have so much free time being single. I recently rebuilt and installed a 300k BTU clean burn waste oil heater which keeps the shop at 70* and is great to work in when it's 12* outside

Dad's marking:

The mess! 360 magnum/A500 big bolt disc brakes!

Test Fit! Filling any holes not needed on firewall and inner fenders and was very happy to see the trans tunnel I made fits like a glove to the trans!

Entire old body is disassembled, bagged and tagged and various documentation points done. Started going through the NOS stash and picking the best parts out. Nice to find things I thought I needed and finding them in the inventory! Next is finish my custom trans mount, weld cowl back on and quarter patch and tear it back down for all chassis parts to be powder coated, trans freshened, engine freshened and epoxy on body!