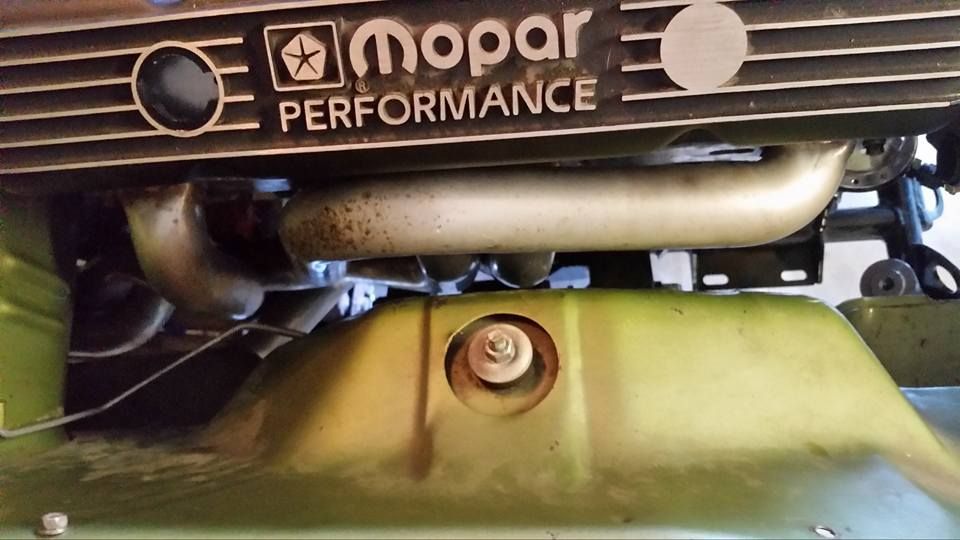

My best friend helped me build this one. Other than modifying the bellcrank, there didn't seem much to it. Proparts headers and when you don't mind cutting access holes in the fenders, for accessing plugs, makes it much easier. Previous owner had already cut holes for fenderwell headers so any additional holes were no big deal. I guess I might have felt differently if it was a show car and I was trying to keep everything looking perfect.

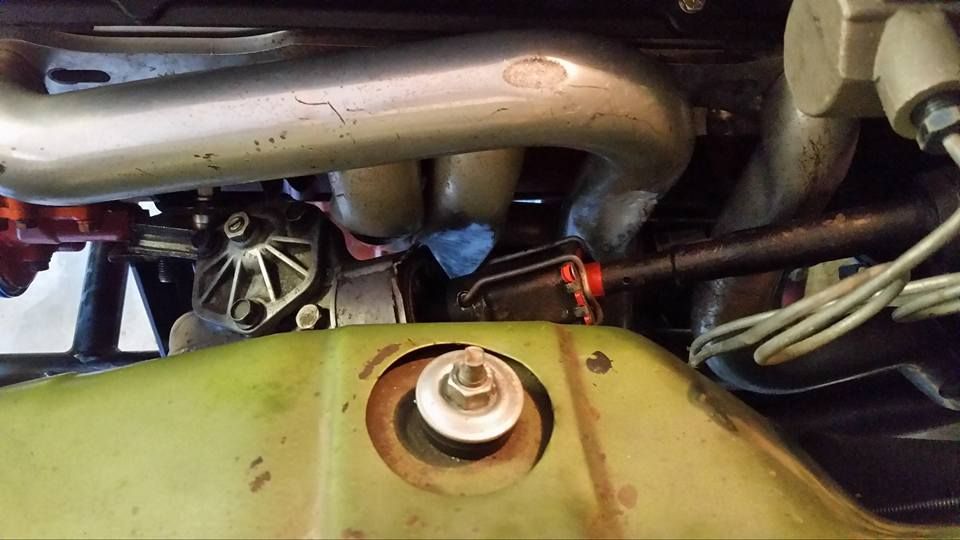

Try shoving an RB into an early A and then tell me about "pain in the A$$".

Try shoving an RB into an early A and then tell me about "pain in the A$$".