COP Ignition Development

It has been hot and humid here, so I found a couple days to work on ignition. Back when I first started this project there was a Plan A and Plan B. Plan A was to use a single sensor in distributor for both timing reference and cylinder index. Plan B, would use two sensors, the timing reference sensor could be done at crank too, for added accuracy. There is more on this on post #25 of this thread. I even wrote code to generate the CAM/Crank signals on the Plan A, for use as tach drive and EFI sync.

With the poor starting performance of Plan A. That is related to a couple things that cannot be easily improved. I decided to try Plan B, and found that in many ways, it is better. It makes the distributor more off the shelf, affordable, and smaller. The ECU firmware is simpler, since the tab window decoding is not necessary. It also makes the ECU hardware and software the same for distributor sensing or CAM/Crank sensing. Cylinder sync is certain, and occurs once per engine revolution, not up to 4 as in Plan A.

In the two days, I built a Plan B distributor, wrote a micro controlled distributor simulator, and roughed out the ECU firmware. The distributor sensing simulator has communications with PC, the timing reference signal phase can be shifted in relation to the CAM signal, and other parameters such as minimum and maximum RPM, and the rate of change for that.

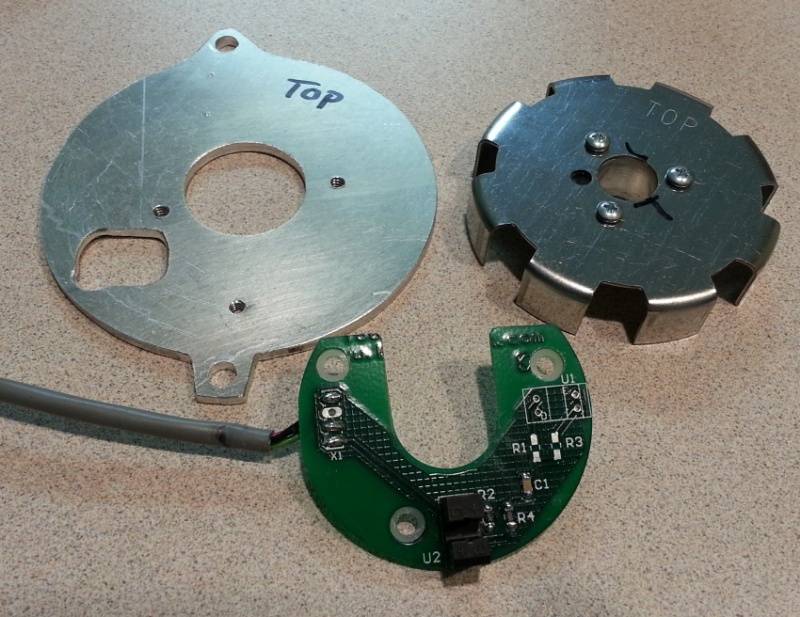

Here are the parts that are the add-on for a $22 30-3899 Hall sensor based CAM/distributor.

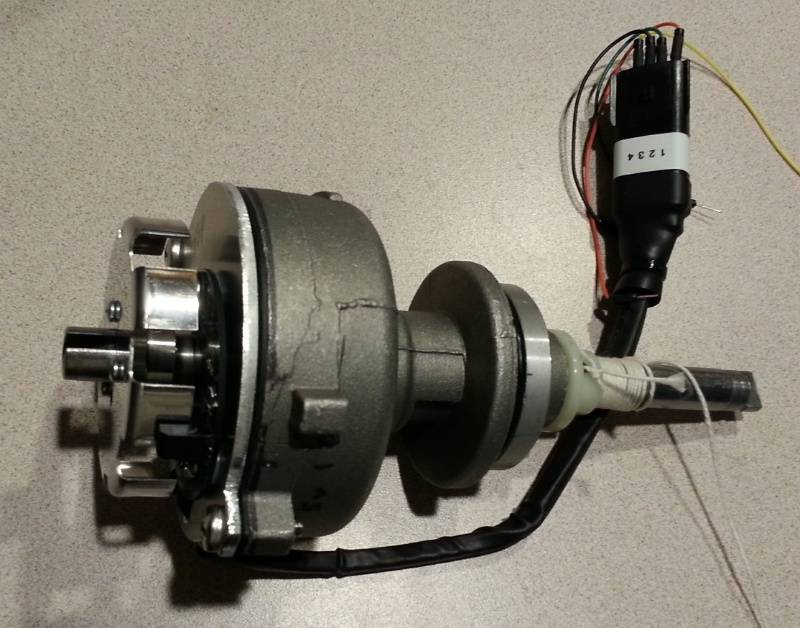

Here is assembled unit, less cap. Wires at connector supply 5V to sensor, connects to sensor outputs for testing. A string was used to rotate shaft for tests.

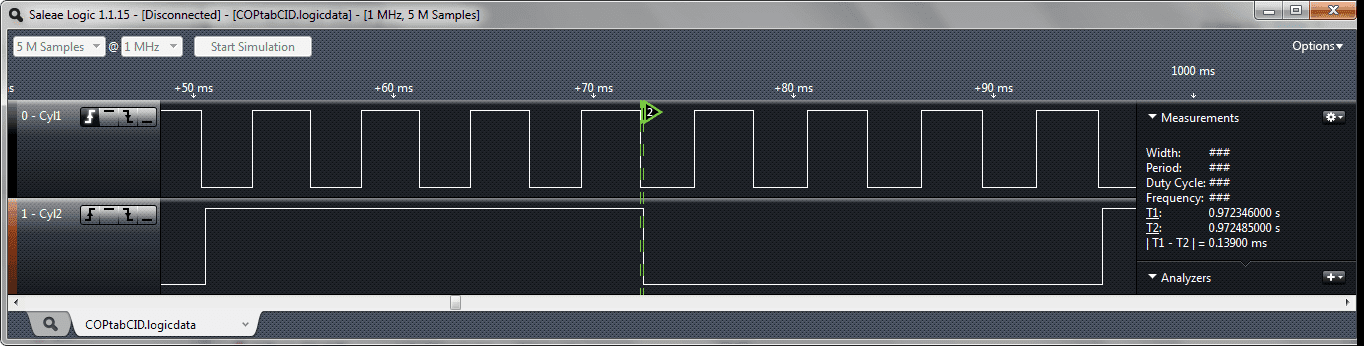

Here are sensor waveforms captured logic analyzer. Top is timing reference, bottom is CAM. Click on image to see it correctly.

Comparison of Plan A top, Plan B bottom. I need to fabricate a nipple-less cap, no need for rotor or terminals.

It has been hot and humid here, so I found a couple days to work on ignition. Back when I first started this project there was a Plan A and Plan B. Plan A was to use a single sensor in distributor for both timing reference and cylinder index. Plan B, would use two sensors, the timing reference sensor could be done at crank too, for added accuracy. There is more on this on post #25 of this thread. I even wrote code to generate the CAM/Crank signals on the Plan A, for use as tach drive and EFI sync.

With the poor starting performance of Plan A. That is related to a couple things that cannot be easily improved. I decided to try Plan B, and found that in many ways, it is better. It makes the distributor more off the shelf, affordable, and smaller. The ECU firmware is simpler, since the tab window decoding is not necessary. It also makes the ECU hardware and software the same for distributor sensing or CAM/Crank sensing. Cylinder sync is certain, and occurs once per engine revolution, not up to 4 as in Plan A.

In the two days, I built a Plan B distributor, wrote a micro controlled distributor simulator, and roughed out the ECU firmware. The distributor sensing simulator has communications with PC, the timing reference signal phase can be shifted in relation to the CAM signal, and other parameters such as minimum and maximum RPM, and the rate of change for that.

Here are the parts that are the add-on for a $22 30-3899 Hall sensor based CAM/distributor.

Here is assembled unit, less cap. Wires at connector supply 5V to sensor, connects to sensor outputs for testing. A string was used to rotate shaft for tests.

Here are sensor waveforms captured logic analyzer. Top is timing reference, bottom is CAM. Click on image to see it correctly.

Comparison of Plan A top, Plan B bottom. I need to fabricate a nipple-less cap, no need for rotor or terminals.