COP Ignition Development

Pishta,

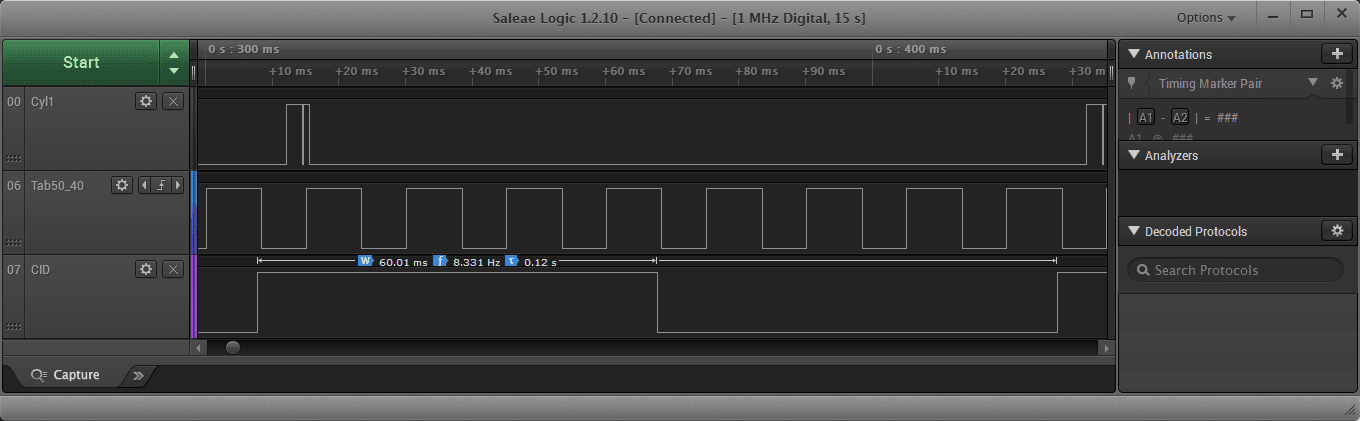

Good you are thinking about this. Here is the desired sensor signals. Click to enlarge.

The lower is CAM up for 4 down for 4. The middle is the tab wheel up for 50 degrees, down for 40 degrees. Timing advance occurs in the 40 degree section. Both signals are locked on the distributor shaft, so turning distributor for base timing both stay in sync. The upper trace is 2-strike ignition at 1000 RPM with only a few degrees of advance. The CID (cylinder identification) is a hall sensor in a standard 1992-1997 Dodge 5.2L distributor. The tab sensor is optical, LED on side photo transistor on other. Signal is high when tab blocks light, goes low when open. Where the edges occur are used by the ECU to control timing, they are regerence points.

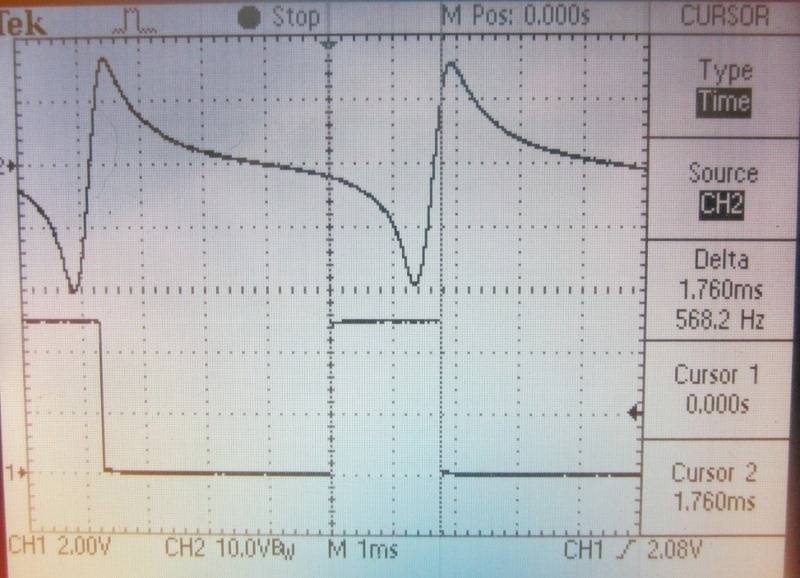

VR sensors only generate voltage for change in flux. Greater change of flux with respect to time, greater the voltage. If metal is in front of sensor and zero speed, voltage is zero. If metal is in front and moving, but same thickness, flux does not change.. zero voltage. Here is a scope view of VR signal from Mopar electronic distributor.

The upper wave is the VR signal with engine turning about 3300 RPM. The place near the middle where there is a sharp slow from the low peak to high peak is where the tooth on the reluctor is passing the pickup. It passes zero when aligned. The trigger point is on the way up. Notice the amplitude of the second pulse is less than the prior one on the left, that is typical of run out. Amplitudes often vary much more and change timing trigger points. The trigger points vary with voltage thresholds of various ignition modules. A VR sensor does not generate digital high and low signals without significant analog circuit.

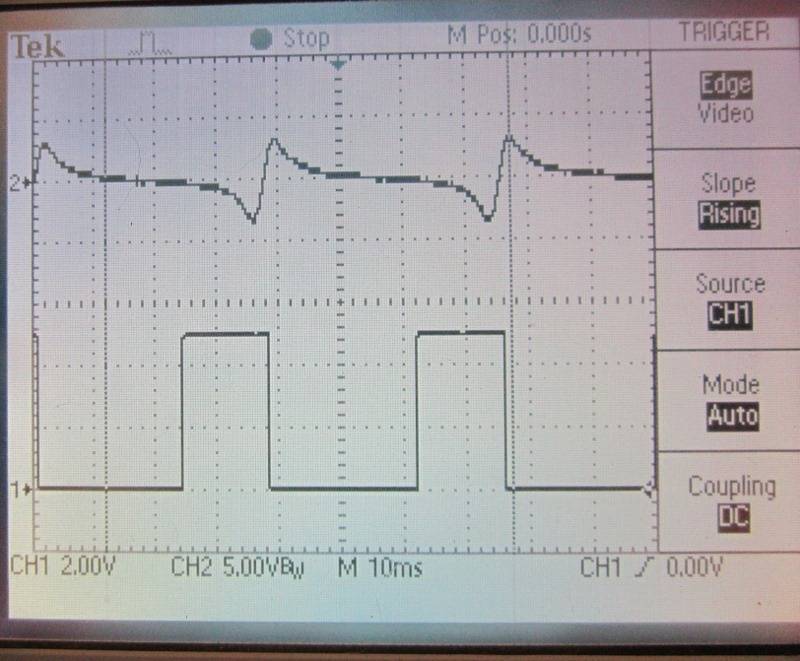

Here is a VR signal at about 300 RPM, notice how the amplitude is less.

The amplitude is about 6V pk-pk, the one above is about 35V pk-pk.

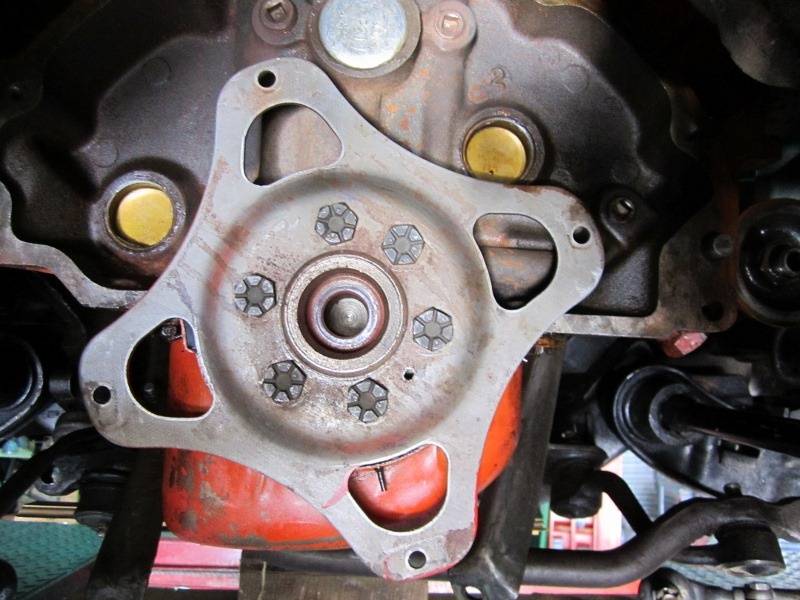

Here is the picture of the flex plate on rear of my 273.

I was thinking it going to be possible to use the spokes and trigger with a Hall sensor. The oil pan prohibits use of a circular threaded sensor. The flex plate is quite close to inspection plate. There is not enough room for tabs, mounting sensor and having adjustment room for base timing would be very difficult. The spokes of the flex plate would not result is a clean and sharp trigger. The trigger needs to be similar to the tab wheel, a clear and sharp trigger. The spokes also have openings, so they would generate additional signals. After markets plates are often solid, and designs changed over years, so I gave up on the rear timing sensor.

So rear sensing has complications, sensor placement, trigger targets, and the difficulty for base timing adjustments. The distributor option is plug and play, easy to static time and adjust, universal in application.

Pishta,

Good you are thinking about this. Here is the desired sensor signals. Click to enlarge.

The lower is CAM up for 4 down for 4. The middle is the tab wheel up for 50 degrees, down for 40 degrees. Timing advance occurs in the 40 degree section. Both signals are locked on the distributor shaft, so turning distributor for base timing both stay in sync. The upper trace is 2-strike ignition at 1000 RPM with only a few degrees of advance. The CID (cylinder identification) is a hall sensor in a standard 1992-1997 Dodge 5.2L distributor. The tab sensor is optical, LED on side photo transistor on other. Signal is high when tab blocks light, goes low when open. Where the edges occur are used by the ECU to control timing, they are regerence points.

VR sensors only generate voltage for change in flux. Greater change of flux with respect to time, greater the voltage. If metal is in front of sensor and zero speed, voltage is zero. If metal is in front and moving, but same thickness, flux does not change.. zero voltage. Here is a scope view of VR signal from Mopar electronic distributor.

The upper wave is the VR signal with engine turning about 3300 RPM. The place near the middle where there is a sharp slow from the low peak to high peak is where the tooth on the reluctor is passing the pickup. It passes zero when aligned. The trigger point is on the way up. Notice the amplitude of the second pulse is less than the prior one on the left, that is typical of run out. Amplitudes often vary much more and change timing trigger points. The trigger points vary with voltage thresholds of various ignition modules. A VR sensor does not generate digital high and low signals without significant analog circuit.

Here is a VR signal at about 300 RPM, notice how the amplitude is less.

The amplitude is about 6V pk-pk, the one above is about 35V pk-pk.

Here is the picture of the flex plate on rear of my 273.

I was thinking it going to be possible to use the spokes and trigger with a Hall sensor. The oil pan prohibits use of a circular threaded sensor. The flex plate is quite close to inspection plate. There is not enough room for tabs, mounting sensor and having adjustment room for base timing would be very difficult. The spokes of the flex plate would not result is a clean and sharp trigger. The trigger needs to be similar to the tab wheel, a clear and sharp trigger. The spokes also have openings, so they would generate additional signals. After markets plates are often solid, and designs changed over years, so I gave up on the rear timing sensor.

So rear sensing has complications, sensor placement, trigger targets, and the difficulty for base timing adjustments. The distributor option is plug and play, easy to static time and adjust, universal in application.