1985 D150 "Mr. Curtis" race truck with a 2015 6.4

The LX platform essentially uses a 30 year old rear axle design of Mercedes Benz.

It first saw the light of day in the W201 chassis (190 series). I have one of these small MBs and they drive awesome.

It's a limousine for four people and zips around corners like a small two-seater. Every now and then i am thinking about putting a turbo on the small 1.8L four cylinder...

Essentially, today everybody uses a variation of this ingenious design. In fact at one point of this project i was looking into the W211s (E-class) rear axle subframe.

Anyhow:

The Ram SRT-10 is a "regular" Ram 1500 with the beefy, boxed steel LCAs, custom spindles for massive 15" rotors and monster four-piston calipers, the actual Viper V10 (there is a "truck-V10" which is not the same engine), the axle shown above (a Dana M60), traction "bars" and a fifth shock to help dampen wheel hop on traction loss.

What i am replicating is a Chevy C10 with SRT genes and the body of an '85 truck. (I started out with 70s trucks but kind of fell for the 80s design lately.)

Stuff that Dodge never cared about after the Lil Red Express and it's brethren (Warlock, Midnight Express, etc.).

The C10s have a nice double-A-arm front suspension, long rear trailing arms with coil springs and a panhard bar.

There's tons of stuff for these and you can build a "race" truck by ordering parts out of a catalog...

But i don't like the round and curvy C10s. I don't like the look of Chevy trucks. I like Dodge trucks.

But Dodge never cared to put a good suspension under their trucks until 2014.

Back to topic.

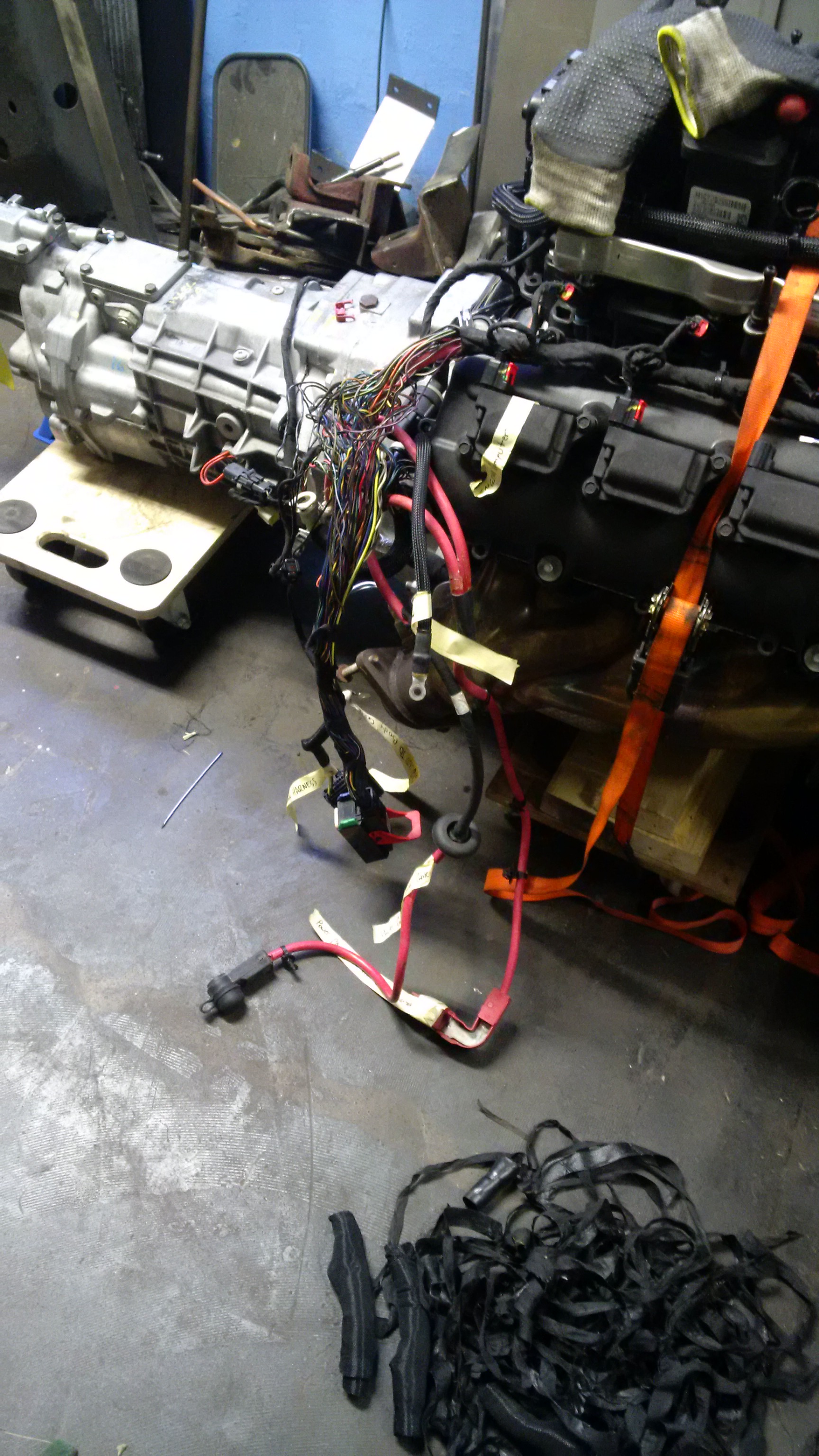

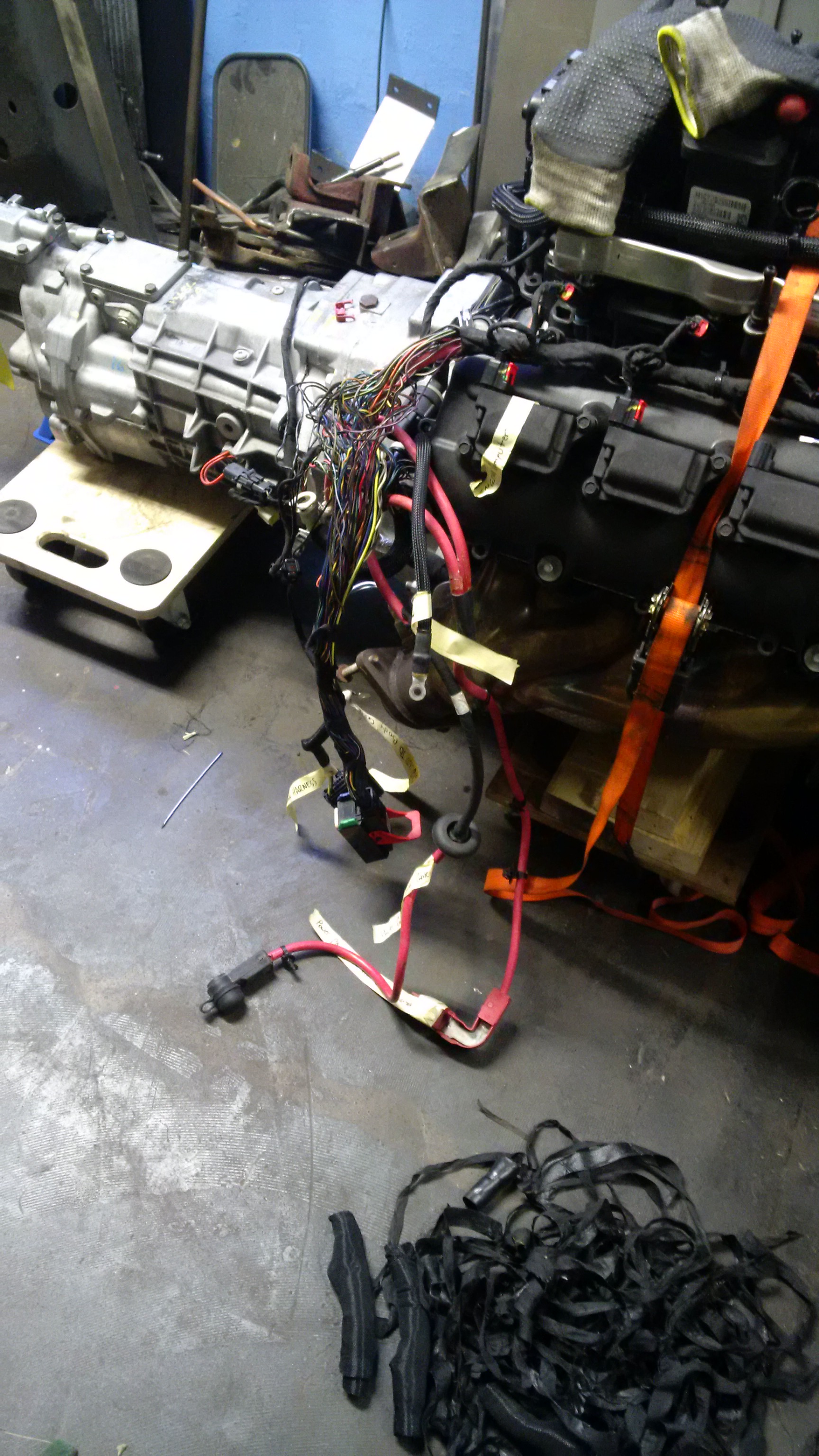

I feared i would have to re-wire the engine harness, to move the ECU to the driver side of the engine compartment.

The LX-cars have the engine computer on the passenger side.

On the passenger side in a truck there's the heater box on the firewall, heater hoses (heat!), wiper washer reservoir and not really that much space for a large ECU.

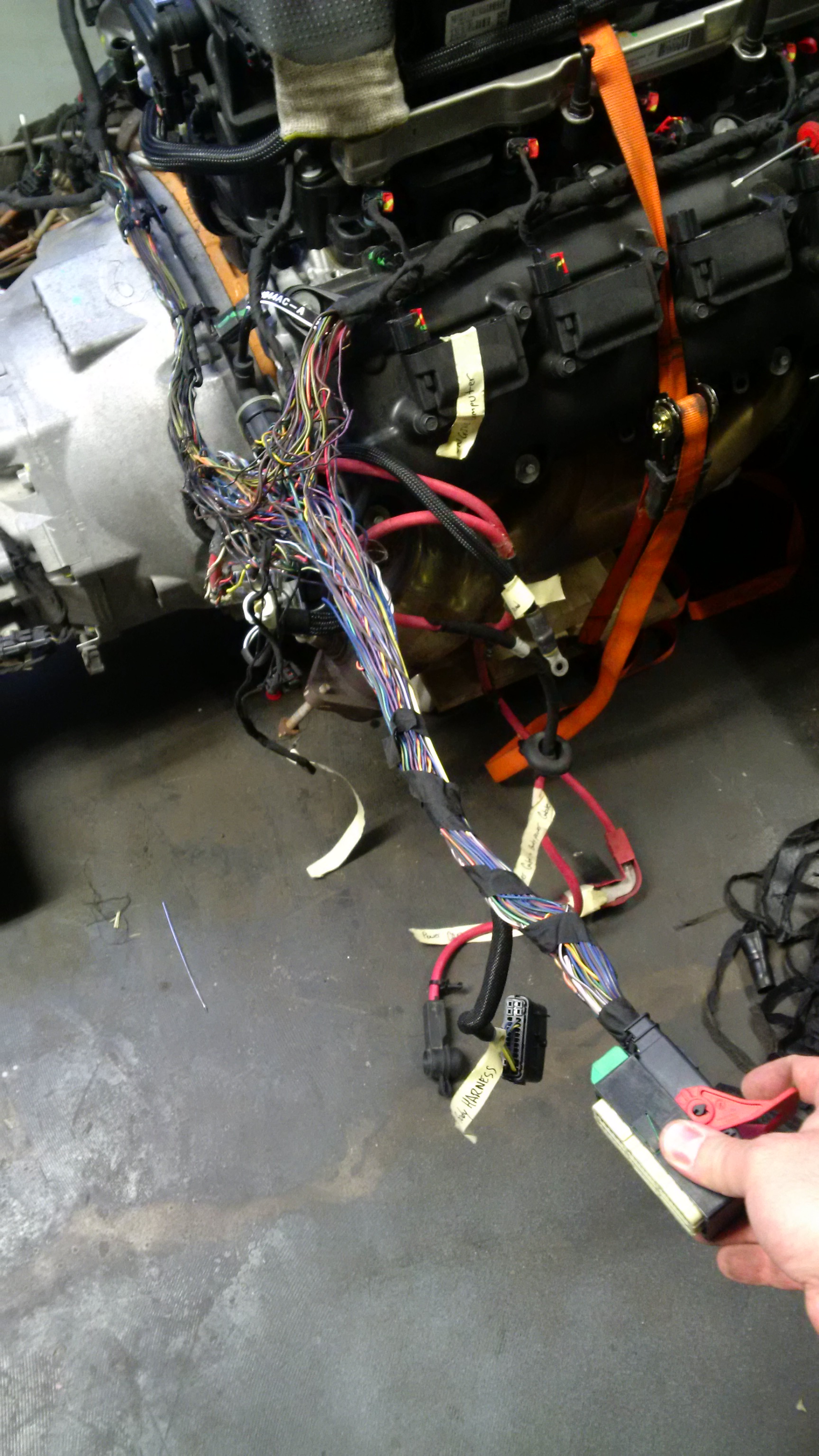

Jumping into cold waters i decided to tear into the engine harness and begun unwrapping it to understand wire-routing and have a look how good my chances would be, to relocate stuff.

It turns out to be a major pita.

But then, solutions came right around the corner.

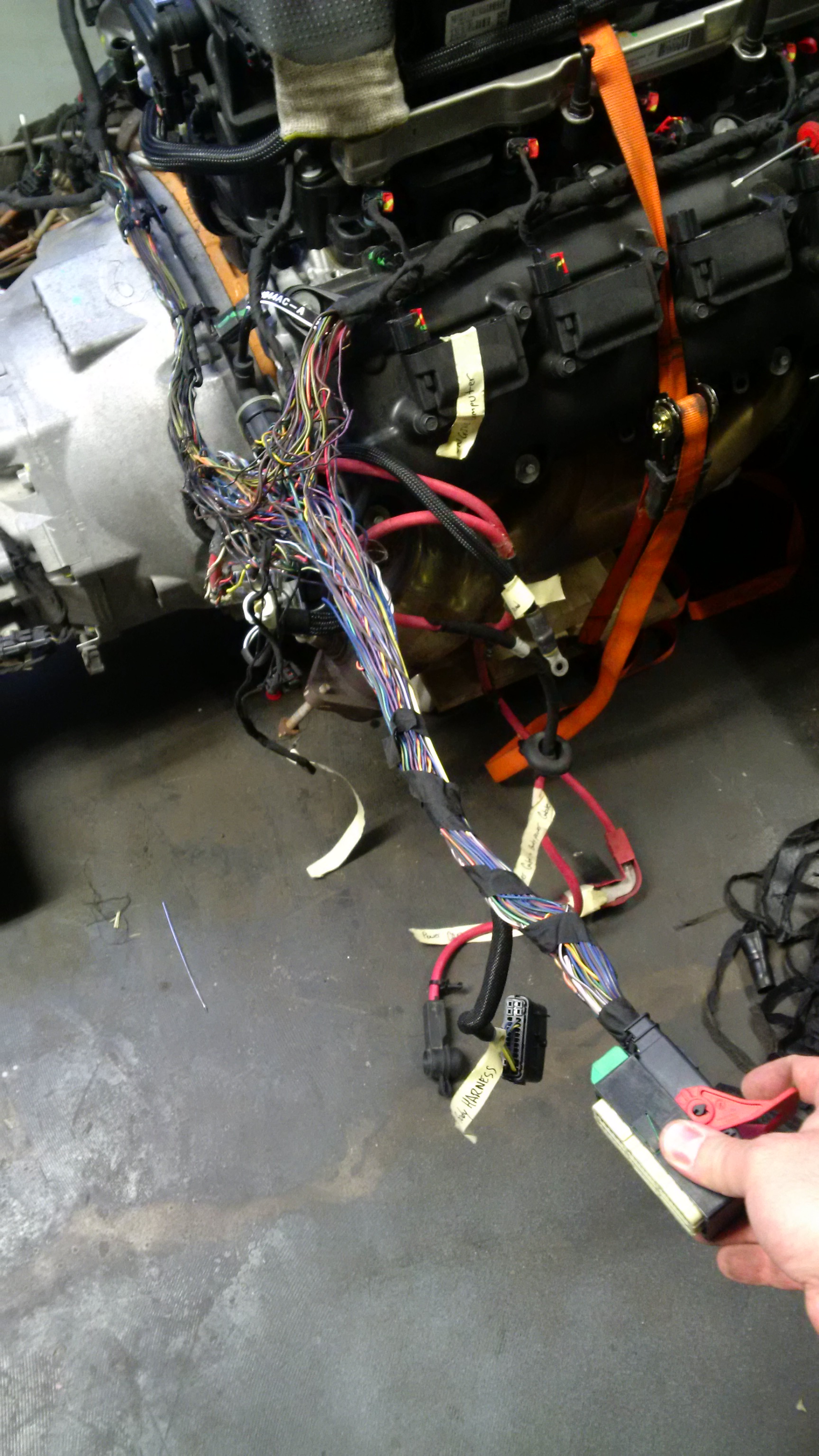

Measuring from the center of the engine bay to the passenger side inner fender i found a distance of about 31".

Which means that the piece of engine harness that connects the engine to the ECU has to be around 30-31" long.

It was not from the factory, because the wiring takes a strange down-and-upward-route.

Unwrapping helped understanding why it did that and showed that it was not really necessary. Unwrapping also disclosed, why the harness feels so stiff:

The glue from some of the shrink-wrapped connections seeped out and glued some of the wires together. Realnice.

I also had to physically move some of the wiring on the passenger side valve cover further to the back of the engine, there's enough slack in the wires to do that.

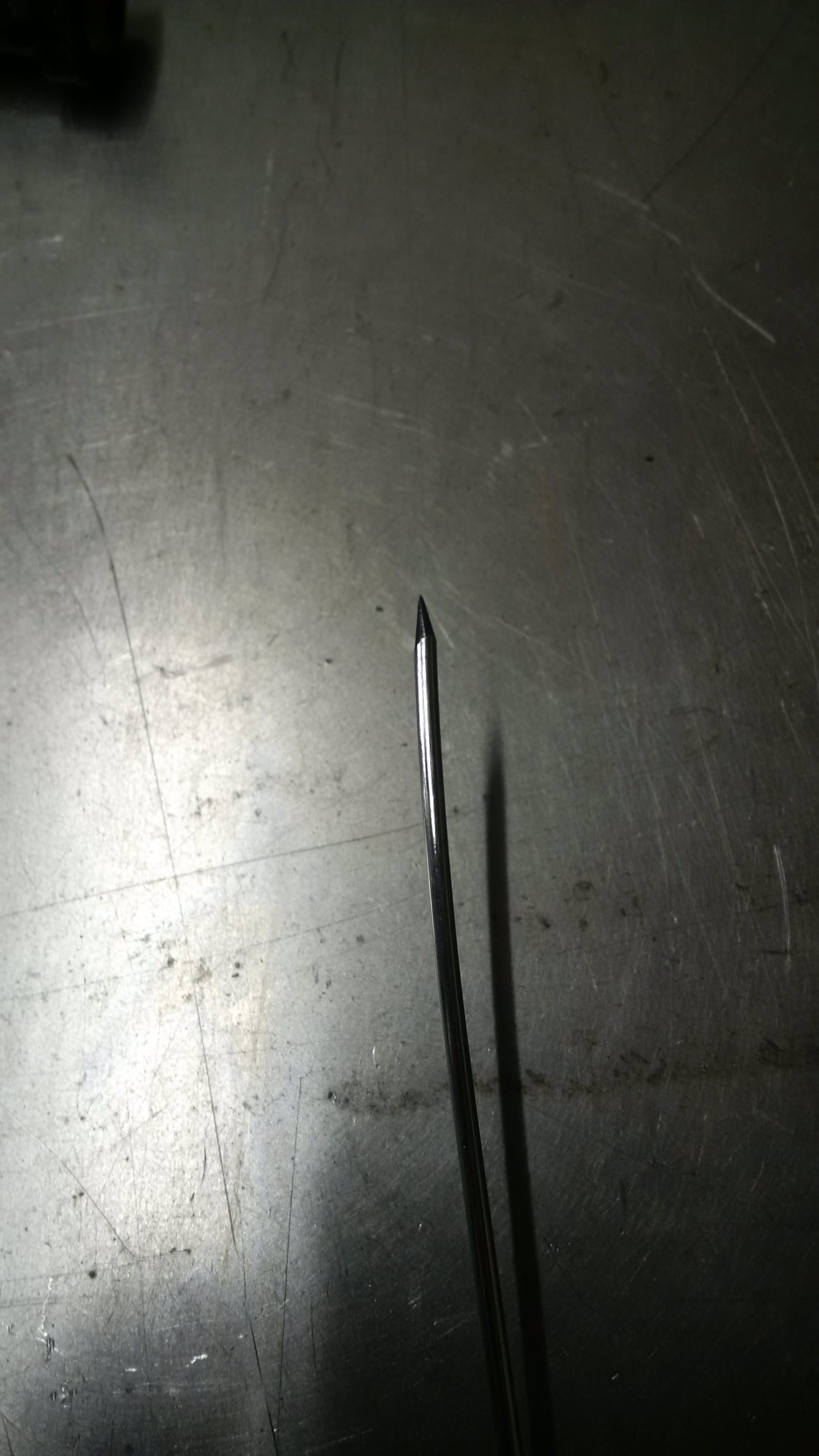

But you will have to move the harness-mounting-pins:

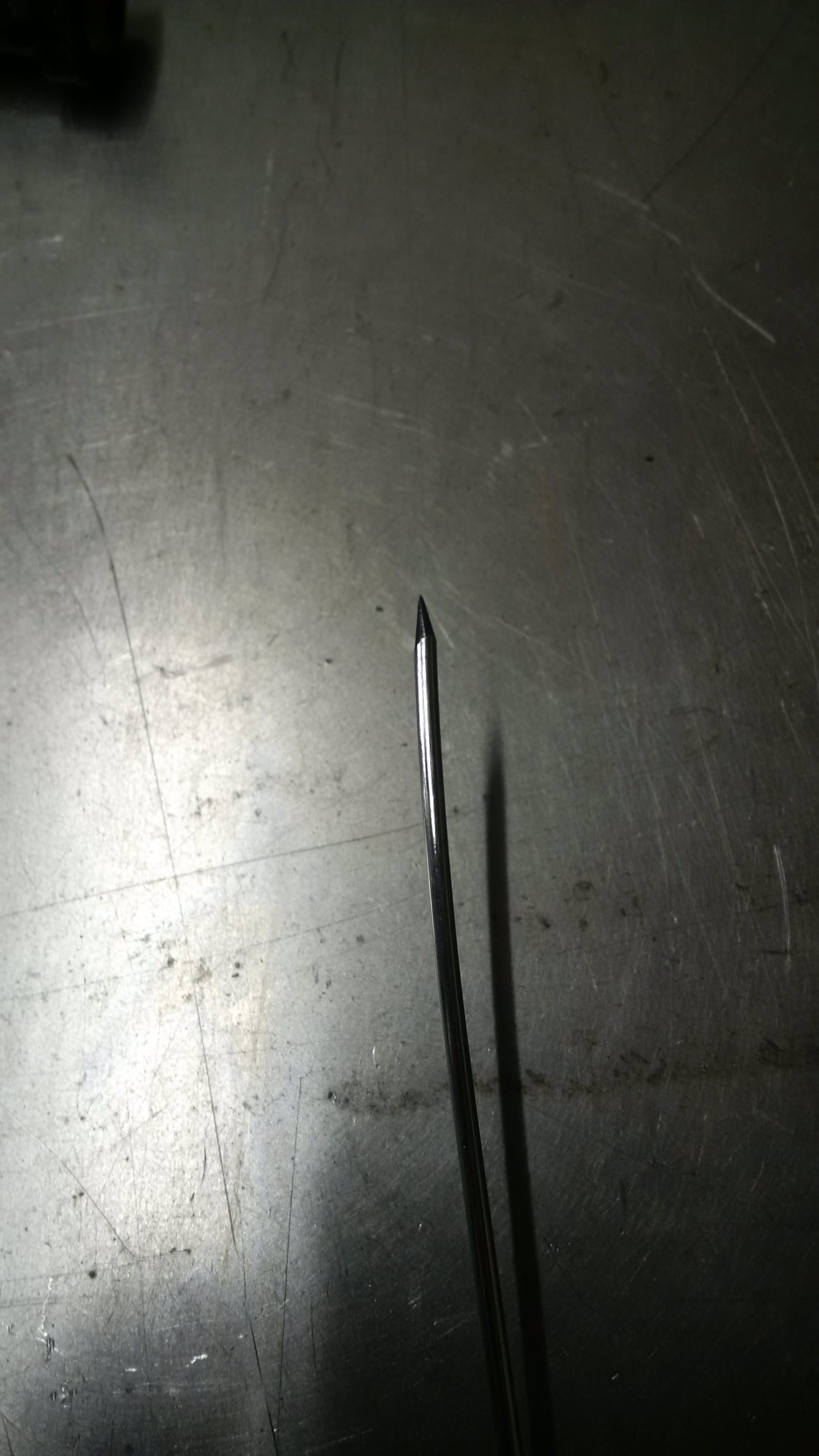

For that i ground a needle point on a piece of hard steel wire, so i could lift the zip-tie-like retainer.

It's mostly untangled by now and ready to be re-wrapped.

I now have the required length of wire and can place the ECU on the passenger side inner fender.

During that process i also found a solution for the heater hoses.

These would make a loop right where the ECU will be located and the heat from these hoses does not play too well with any kind of computer i think.

To my fortune, the engine brought all the necessary parts with it to do this:

Routes the heater hoses neatly over the heater box to the backside of the engine, where the heater hose connections are located. Win!

The LX platform essentially uses a 30 year old rear axle design of Mercedes Benz.

It first saw the light of day in the W201 chassis (190 series). I have one of these small MBs and they drive awesome.

It's a limousine for four people and zips around corners like a small two-seater. Every now and then i am thinking about putting a turbo on the small 1.8L four cylinder...

Essentially, today everybody uses a variation of this ingenious design. In fact at one point of this project i was looking into the W211s (E-class) rear axle subframe.

Anyhow:

The Ram SRT-10 is a "regular" Ram 1500 with the beefy, boxed steel LCAs, custom spindles for massive 15" rotors and monster four-piston calipers, the actual Viper V10 (there is a "truck-V10" which is not the same engine), the axle shown above (a Dana M60), traction "bars" and a fifth shock to help dampen wheel hop on traction loss.

What i am replicating is a Chevy C10 with SRT genes and the body of an '85 truck. (I started out with 70s trucks but kind of fell for the 80s design lately.)

Stuff that Dodge never cared about after the Lil Red Express and it's brethren (Warlock, Midnight Express, etc.).

The C10s have a nice double-A-arm front suspension, long rear trailing arms with coil springs and a panhard bar.

There's tons of stuff for these and you can build a "race" truck by ordering parts out of a catalog...

But i don't like the round and curvy C10s. I don't like the look of Chevy trucks. I like Dodge trucks.

But Dodge never cared to put a good suspension under their trucks until 2014.

Back to topic.

I feared i would have to re-wire the engine harness, to move the ECU to the driver side of the engine compartment.

The LX-cars have the engine computer on the passenger side.

On the passenger side in a truck there's the heater box on the firewall, heater hoses (heat!), wiper washer reservoir and not really that much space for a large ECU.

Jumping into cold waters i decided to tear into the engine harness and begun unwrapping it to understand wire-routing and have a look how good my chances would be, to relocate stuff.

It turns out to be a major pita.

But then, solutions came right around the corner.

Measuring from the center of the engine bay to the passenger side inner fender i found a distance of about 31".

Which means that the piece of engine harness that connects the engine to the ECU has to be around 30-31" long.

It was not from the factory, because the wiring takes a strange down-and-upward-route.

Unwrapping helped understanding why it did that and showed that it was not really necessary. Unwrapping also disclosed, why the harness feels so stiff:

The glue from some of the shrink-wrapped connections seeped out and glued some of the wires together. Realnice.

I also had to physically move some of the wiring on the passenger side valve cover further to the back of the engine, there's enough slack in the wires to do that.

But you will have to move the harness-mounting-pins:

For that i ground a needle point on a piece of hard steel wire, so i could lift the zip-tie-like retainer.

It's mostly untangled by now and ready to be re-wrapped.

I now have the required length of wire and can place the ECU on the passenger side inner fender.

During that process i also found a solution for the heater hoses.

These would make a loop right where the ECU will be located and the heat from these hoses does not play too well with any kind of computer i think.

To my fortune, the engine brought all the necessary parts with it to do this:

Routes the heater hoses neatly over the heater box to the backside of the engine, where the heater hose connections are located. Win!