Another Mopar Off My Bucket List - Barracuda Fastback

I never get as much accomplished as what I plan. It's not that I don't try, but I move pretty slow and need to take a lot of breaks. I guess my planned objectives are on a time schedule I used to be able to keep pace with.

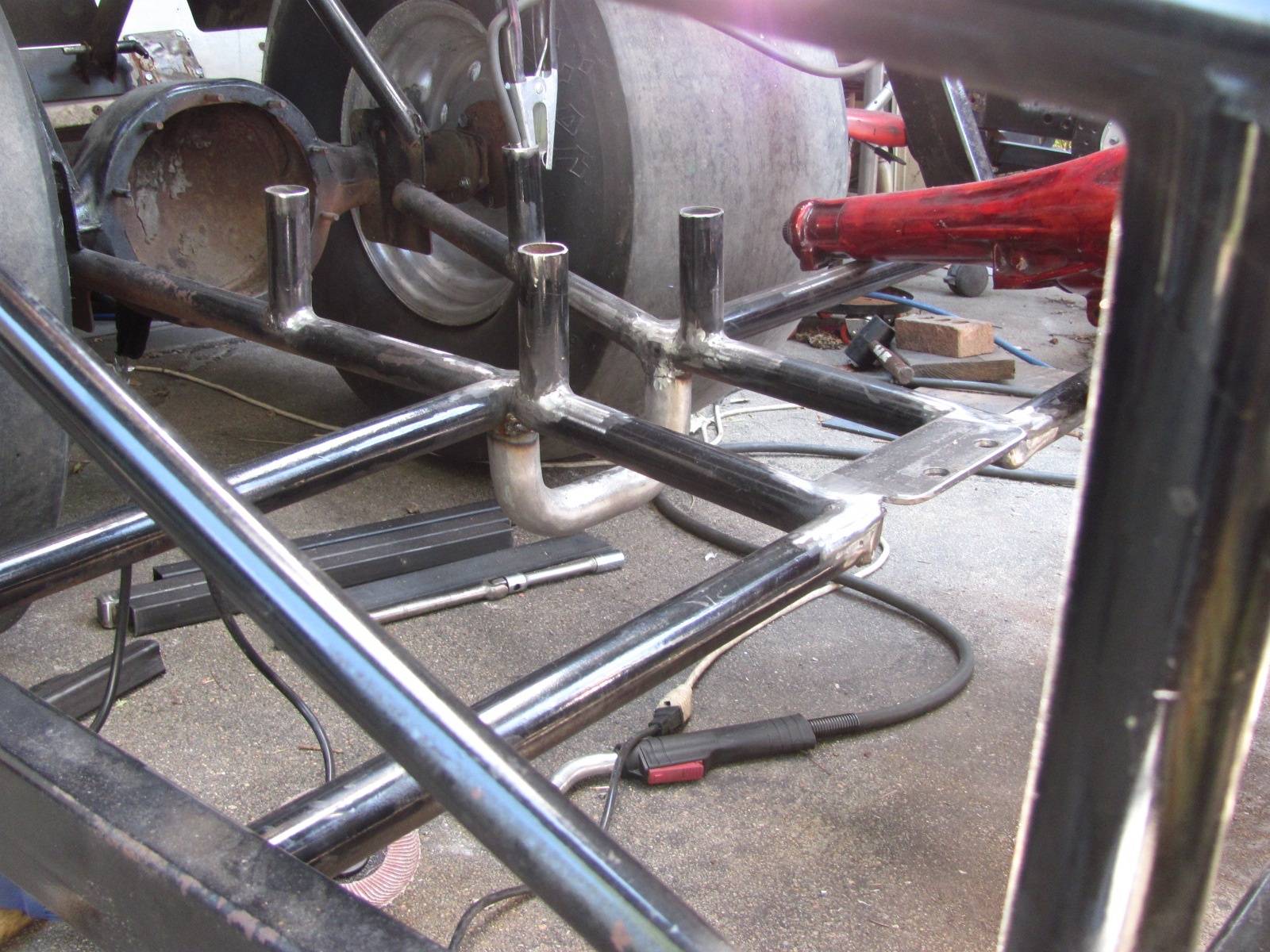

Nonetheless, I did make further progress today. I started out fabricating a rear transmission mount. I oversized the holes to allow for the transmission to slide forward if I eliminate the 1/4" extra space the rear engine plate uses. I'll use large washers when it's bolted together. I also cut out the last bar that interfered with the future driveshaft.

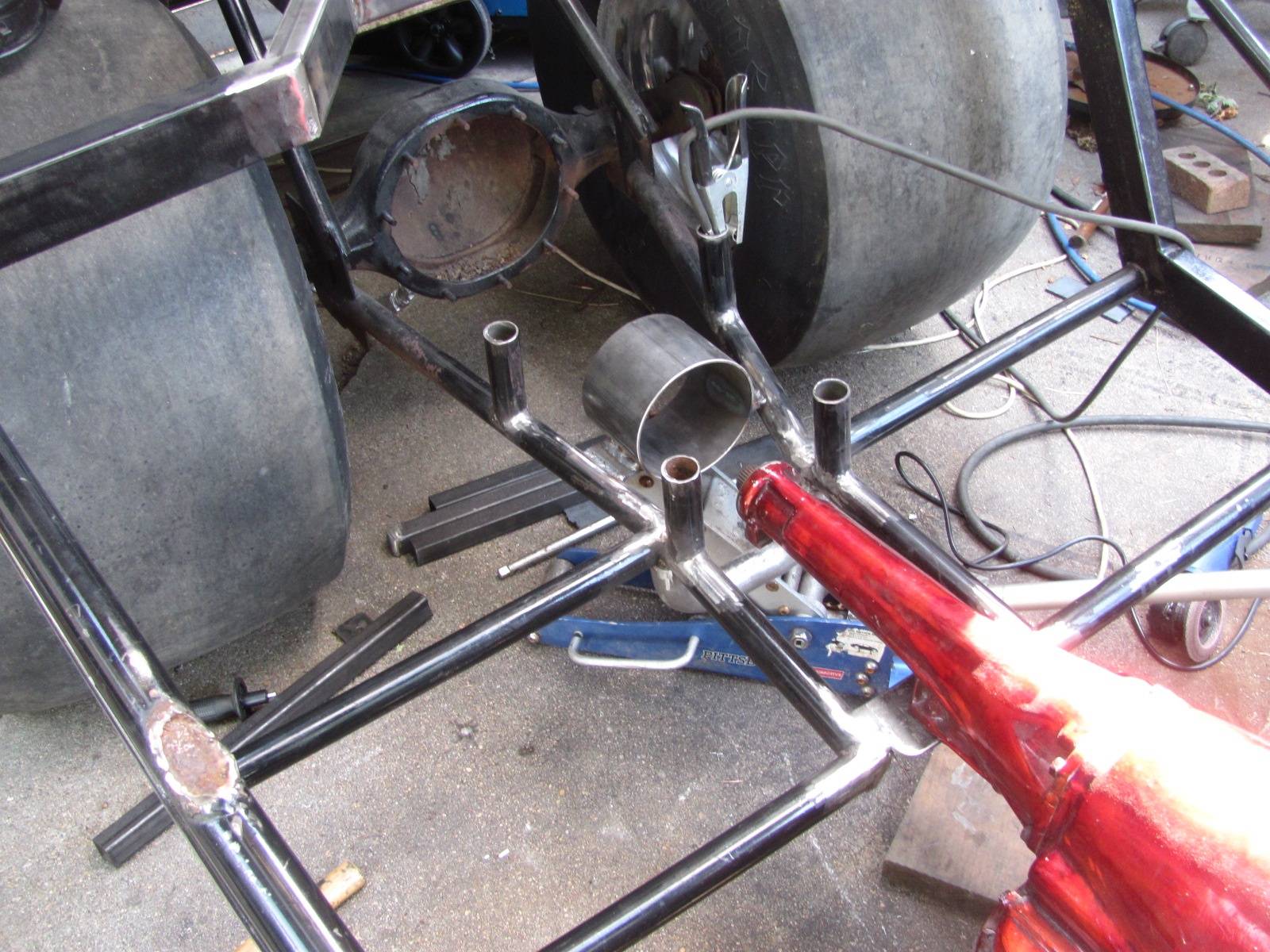

After finishing the transmission mount I welded in a dropped frame cross-member to take the place of the bar I'd cut out. I fabbed the new cross-member out of 4 45' steel elbows and 3 short sections of 1&1/2" tubing. All welded up it looks like a single bent piece.

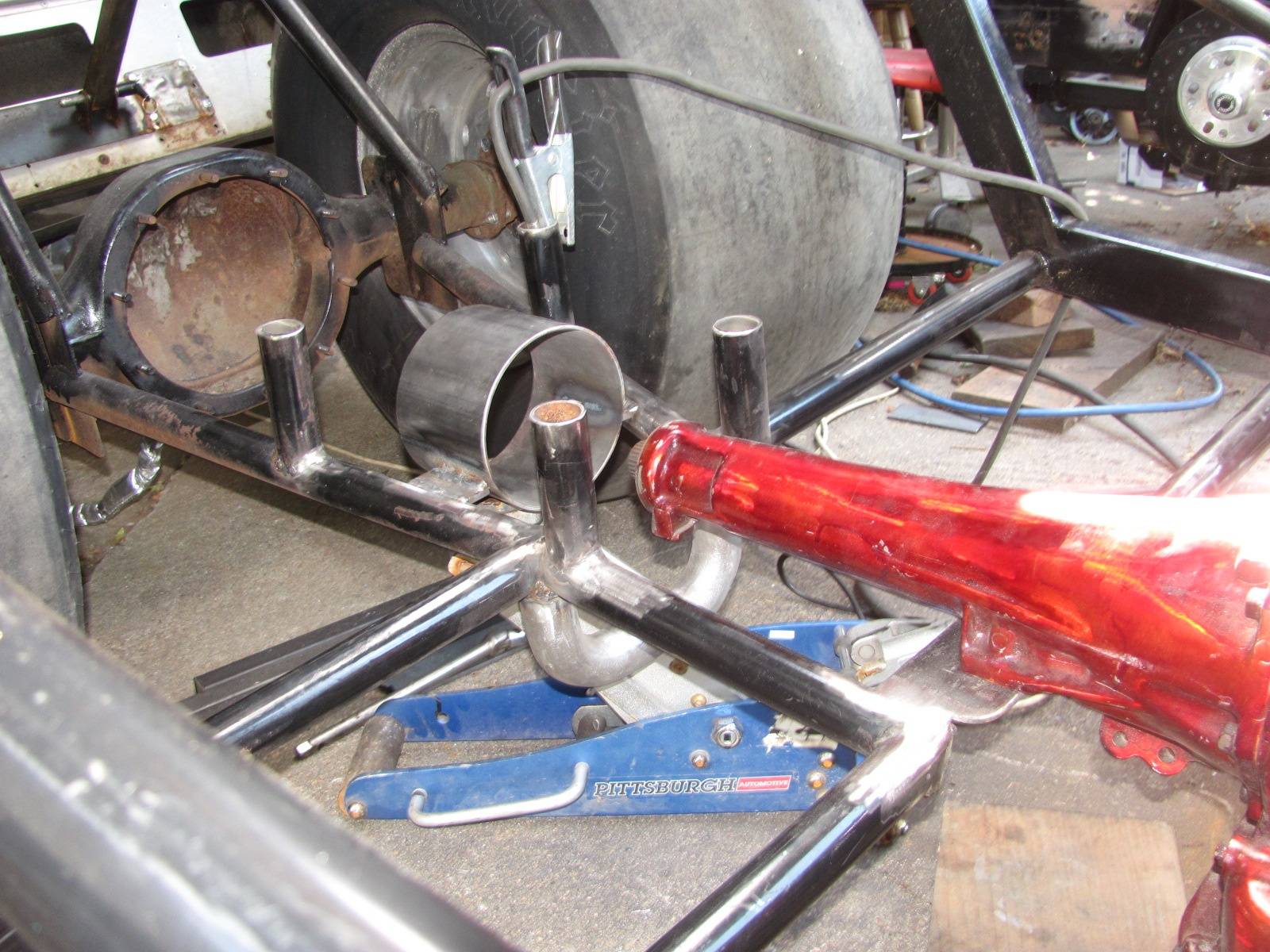

After that I went ahead and welded in the driveshaft loop that I made. Having to remove and re-install the transmission several times is starting to scratch up the pretty red paint. - Oh well.

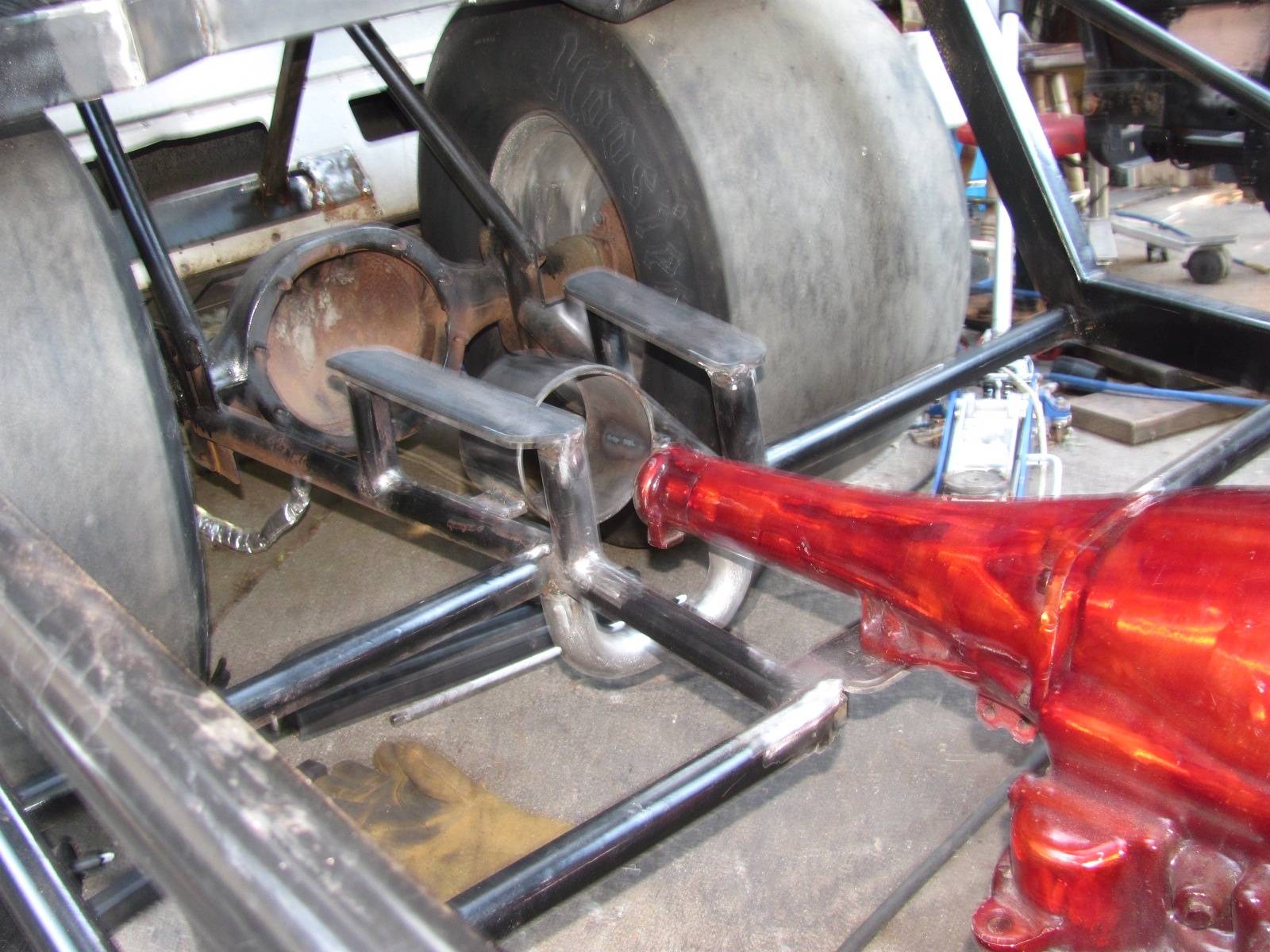

With the loop done I went ahead and welded the 2 straps that the seat bolts down to. They look a little odd but I made them that way on purpose. It's hard to explain, but there's a method to my madness.

The seat is the right height with the roof now. I still need to drill the holes in my brackets so I can bolt it back down.

My next move was to start working on that floor. Rather than cut out the old round cross-members and raise them, I decided to add 1&1/4" square tubing above that would match the height of the original rectangular cross-members & frame. - That way I wouldn't be drilling into (and weakening) the existing cross-members.

I didn't get done before the sun started setting. I only got half of it tacked together. I'll pull these pieces back off and weld any of the bottom seams before laying it back in place and frying it all up.

Tomorrow I need to pull the engine back out (again) so I can notch the aluminum rear motor plate. I want it to rest on the floor supports I was working on today when it's done. It's probably futile to say how much will get done when I get up in the morning. I really think I'll be able to finish the floor structure, the body hinges, and the fuel cell support. One thing that was pretty time consuming was capping off each of the cross-members I whacked. I really wish that rotisserie was here. I've been burning the crap out of myself crawling under the chassis and welding.

I never get as much accomplished as what I plan. It's not that I don't try, but I move pretty slow and need to take a lot of breaks. I guess my planned objectives are on a time schedule I used to be able to keep pace with.

Nonetheless, I did make further progress today. I started out fabricating a rear transmission mount. I oversized the holes to allow for the transmission to slide forward if I eliminate the 1/4" extra space the rear engine plate uses. I'll use large washers when it's bolted together. I also cut out the last bar that interfered with the future driveshaft.

After finishing the transmission mount I welded in a dropped frame cross-member to take the place of the bar I'd cut out. I fabbed the new cross-member out of 4 45' steel elbows and 3 short sections of 1&1/2" tubing. All welded up it looks like a single bent piece.

After that I went ahead and welded in the driveshaft loop that I made. Having to remove and re-install the transmission several times is starting to scratch up the pretty red paint. - Oh well.

With the loop done I went ahead and welded the 2 straps that the seat bolts down to. They look a little odd but I made them that way on purpose. It's hard to explain, but there's a method to my madness.

The seat is the right height with the roof now. I still need to drill the holes in my brackets so I can bolt it back down.

My next move was to start working on that floor. Rather than cut out the old round cross-members and raise them, I decided to add 1&1/4" square tubing above that would match the height of the original rectangular cross-members & frame. - That way I wouldn't be drilling into (and weakening) the existing cross-members.

I didn't get done before the sun started setting. I only got half of it tacked together. I'll pull these pieces back off and weld any of the bottom seams before laying it back in place and frying it all up.

Tomorrow I need to pull the engine back out (again) so I can notch the aluminum rear motor plate. I want it to rest on the floor supports I was working on today when it's done. It's probably futile to say how much will get done when I get up in the morning. I really think I'll be able to finish the floor structure, the body hinges, and the fuel cell support. One thing that was pretty time consuming was capping off each of the cross-members I whacked. I really wish that rotisserie was here. I've been burning the crap out of myself crawling under the chassis and welding.