fried_daddy

Member

Hello,

This transmission is backyard built and ready! I took on this rebuild project for a friend and I took lots of pictures along the way of the disassembly process. This was my first time rebuilding a 904 transmission and I thought that this would be a good place to post the pics for reference if anybody needs it. The transmission I rebuilt was a 904 transmission with the heavy duty rear band and lock up converter.

I used a rebuild kit from Summit Racing. Performance Automatic, kit number PAKT12701, with shift kit and band included. I installed the shift kit using the street settings.

I had to order the rear band separately. I also had to order additional clutch and friction plate for one of the clutch packs in order to get the correct clutch clearance.

The transmission had been going forward in every gear and after disassembly, we figured out why. The clutch pack was welded together.

Old torque converter.

New band that was ordered off Ebay.

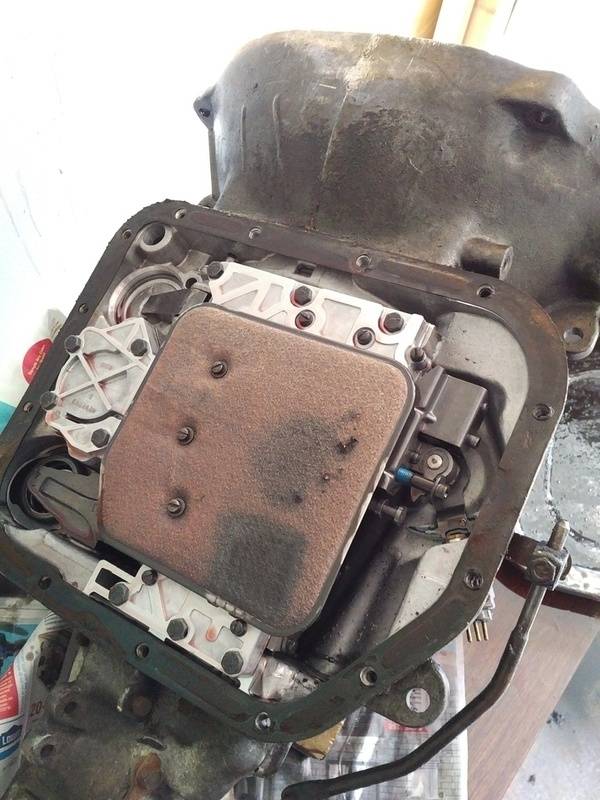

After removing the pan.

The filter did it's job of keeping the foreign material from going through the transmission.

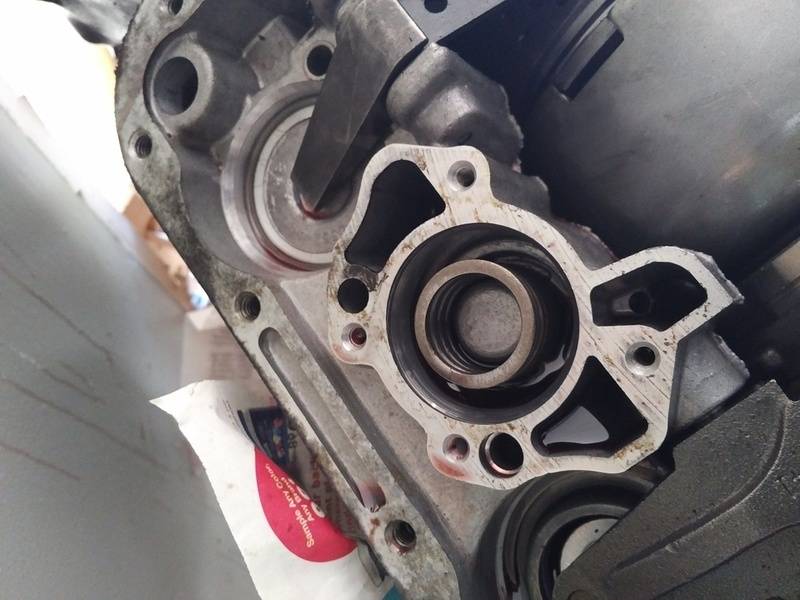

Removing the front pump.

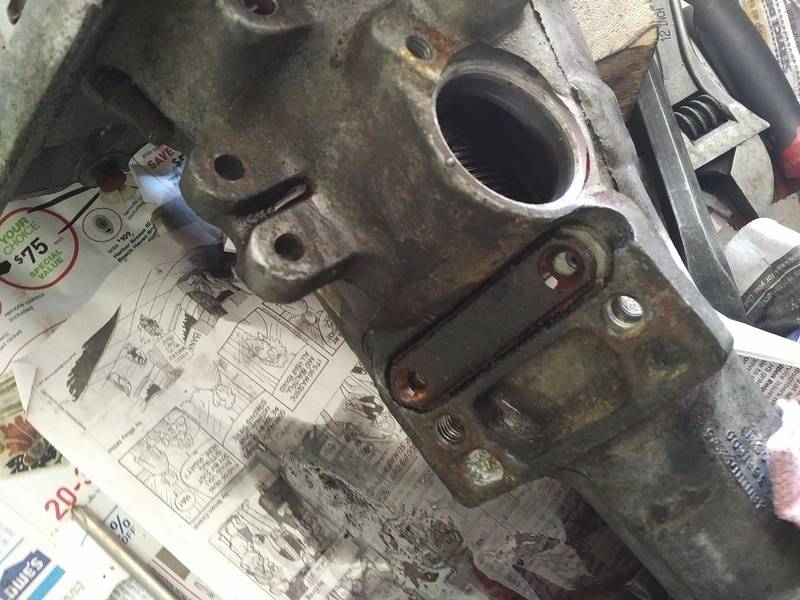

One of the screws on the snap ring cover for the extension housing was a huge PAIN. I ended up using an hand held, hit with the hammer, impact driver to get it off.

Snap ring to remove the extension housing.

Snap ring to remove this bearing.

Snap ring to remove governor.

This transmission is backyard built and ready! I took on this rebuild project for a friend and I took lots of pictures along the way of the disassembly process. This was my first time rebuilding a 904 transmission and I thought that this would be a good place to post the pics for reference if anybody needs it. The transmission I rebuilt was a 904 transmission with the heavy duty rear band and lock up converter.

I used a rebuild kit from Summit Racing. Performance Automatic, kit number PAKT12701, with shift kit and band included. I installed the shift kit using the street settings.

I had to order the rear band separately. I also had to order additional clutch and friction plate for one of the clutch packs in order to get the correct clutch clearance.

The transmission had been going forward in every gear and after disassembly, we figured out why. The clutch pack was welded together.

Old torque converter.

New band that was ordered off Ebay.

After removing the pan.

The filter did it's job of keeping the foreign material from going through the transmission.

Removing the front pump.

One of the screws on the snap ring cover for the extension housing was a huge PAIN. I ended up using an hand held, hit with the hammer, impact driver to get it off.

Snap ring to remove the extension housing.

Snap ring to remove this bearing.

Snap ring to remove governor.