The Great Pumpkin - '71 Duster

OK, made some good progress these last few weeks. Cooling system seems to be straightened out for now as well as the other accessories., just need to finish up wiring it. Punch list is pretty short after that.

Got the driver's side header on finally, what a P.I.T.A. I must have wrestled with it for an hour before I was able to thread the #5 bolt in. I can almost guarantee there will be an exhaust leak because every time I had to move the header, the gasket would get smushed or pulled or drop between something. I was trying not to spray it with sticky copper crap because if/when you need to get the header off, the gasket always tears and can be really tough to get off completely. But, the only way to get it to stay in place was to spray it. Should have done it from the start because if I have to take it off, I'll be scraping it now anyway.

After a lot of headaches, the cooling system seems to have come together nicely. The ECP radiator didn't work out like I had hoped. The brackets didn't line up at all, the whole thing was too tall and the fit and finish was not the greatest. I was on the fence about keeping it so I decided not to mess with it.

So I puled the Griffin back out and took it to a radiator shop to have it tested for leaks. It tested out OK so I had them move the lower water pump inlet to the driver side and weld on some brackets for the HHR fan. This actually solved ALL my problems with the cooling system and accessories.

Here's what it looks like now. The HHR fan fits like it was made for a 22" radiator. There are some brackets that needed to be cut off the sides and some of the shroud needed to be ground down for the hoses to clear but it dropped right in otherwise.

The guy who moved the outlet and welded the brackets on it did a fairly crude job but it does not leak and he didn't charge me a lot. I modified the brackets a little to give them a little more finished look. The holes I drilled are crooked and the edges are pretty uneven but frankly, it looks way better now than when I first got it back.

With an electric fan comes the need for a controller. After a lot of research, I wound up with a Flex-A-Lite #31163. This particular controller is adjustable and has a nice feature which helps with electrical load; the fan comes on at only 60% and goes to 100% on when the temp rises 10 degrees. That really helps to smooth out the large amperage spikes that the electrical system sees when a fan comes on full blast.

I went back and forth with where to mount the controller box. The driver's side inner fender was getting cluttered and I didn't want to have to splice a bunch of wires together so I put it right on the shroud. Luckily there was nice, flat spot that was large enough to put the unit on. It worked out perfect, didn't even have to splice in any extra wire for the fan motor. I have to run the power wire back to an auxiliary junction point but that's all that's left.

So not having to move the alternator alleviated a lot of hassle since I was able to re-use my existing brackets and wiring. I am sticking with the Denso/Toyota alternator for now, hopefully it will be enough for the electric water pump and fan.

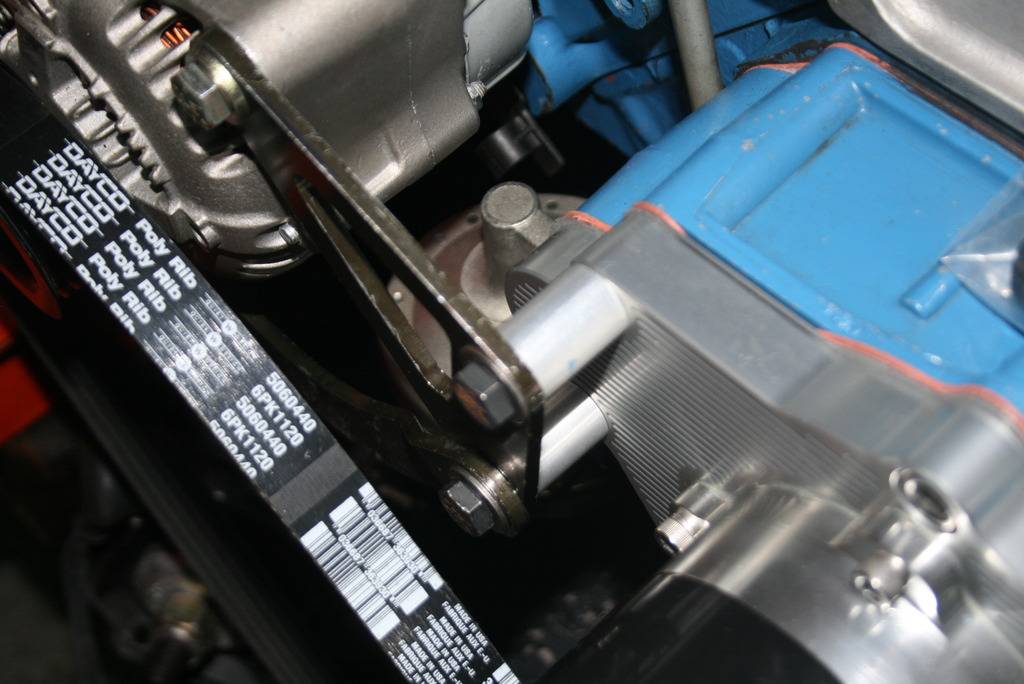

To mount the alternator, I needed some stand-offs for the bracket since the electric pump body not as deep as a regular water pump. I had a long aluminum spacer from another bracket kit on the shelf that I decided to re-purpose. I gave it to my neighbor down the block from me who is a machinist and life-long Mopar man. 10 minutes in the lathe and I have some bitchin' lightweight, counter-bored stand-offs. The pulleys line up perfect. Thanks Howard!

Stand offs.

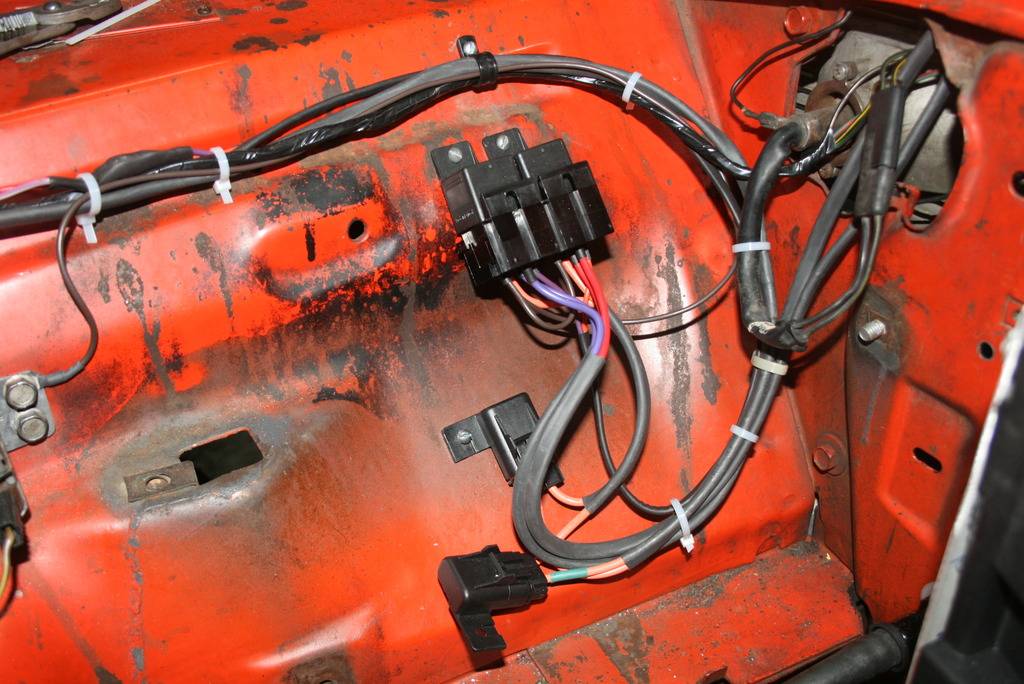

So with some higher-amp draws now on board, I thought it was time to get one of Crackedback's headlight relay kits to help reduce some of the load on the alternator when the lights are on. Rob makes a nice kit that plugs into your existing harness but I wanted to eliminate some of the excess wiring that is left when you install the kit. The old harness had seen better days so it was taken out to be freshened up. The unnecessary wires were removed and the whole thing was re-wrapped.

So yeah, things are looking better. Having the car ready for Mopars at the Valley this weekend is out the window but I'm still holding out hope I can get it down the track this year. I'm confident I will be able to drive it soon but realistically, there may not be enough time before winter to get it sorted out. We'll see.

More to come.

OK, made some good progress these last few weeks. Cooling system seems to be straightened out for now as well as the other accessories., just need to finish up wiring it. Punch list is pretty short after that.

Got the driver's side header on finally, what a P.I.T.A. I must have wrestled with it for an hour before I was able to thread the #5 bolt in. I can almost guarantee there will be an exhaust leak because every time I had to move the header, the gasket would get smushed or pulled or drop between something. I was trying not to spray it with sticky copper crap because if/when you need to get the header off, the gasket always tears and can be really tough to get off completely. But, the only way to get it to stay in place was to spray it. Should have done it from the start because if I have to take it off, I'll be scraping it now anyway.

After a lot of headaches, the cooling system seems to have come together nicely. The ECP radiator didn't work out like I had hoped. The brackets didn't line up at all, the whole thing was too tall and the fit and finish was not the greatest. I was on the fence about keeping it so I decided not to mess with it.

So I puled the Griffin back out and took it to a radiator shop to have it tested for leaks. It tested out OK so I had them move the lower water pump inlet to the driver side and weld on some brackets for the HHR fan. This actually solved ALL my problems with the cooling system and accessories.

Here's what it looks like now. The HHR fan fits like it was made for a 22" radiator. There are some brackets that needed to be cut off the sides and some of the shroud needed to be ground down for the hoses to clear but it dropped right in otherwise.

The guy who moved the outlet and welded the brackets on it did a fairly crude job but it does not leak and he didn't charge me a lot. I modified the brackets a little to give them a little more finished look. The holes I drilled are crooked and the edges are pretty uneven but frankly, it looks way better now than when I first got it back.

With an electric fan comes the need for a controller. After a lot of research, I wound up with a Flex-A-Lite #31163. This particular controller is adjustable and has a nice feature which helps with electrical load; the fan comes on at only 60% and goes to 100% on when the temp rises 10 degrees. That really helps to smooth out the large amperage spikes that the electrical system sees when a fan comes on full blast.

I went back and forth with where to mount the controller box. The driver's side inner fender was getting cluttered and I didn't want to have to splice a bunch of wires together so I put it right on the shroud. Luckily there was nice, flat spot that was large enough to put the unit on. It worked out perfect, didn't even have to splice in any extra wire for the fan motor. I have to run the power wire back to an auxiliary junction point but that's all that's left.

So not having to move the alternator alleviated a lot of hassle since I was able to re-use my existing brackets and wiring. I am sticking with the Denso/Toyota alternator for now, hopefully it will be enough for the electric water pump and fan.

To mount the alternator, I needed some stand-offs for the bracket since the electric pump body not as deep as a regular water pump. I had a long aluminum spacer from another bracket kit on the shelf that I decided to re-purpose. I gave it to my neighbor down the block from me who is a machinist and life-long Mopar man. 10 minutes in the lathe and I have some bitchin' lightweight, counter-bored stand-offs. The pulleys line up perfect. Thanks Howard!

Stand offs.

So with some higher-amp draws now on board, I thought it was time to get one of Crackedback's headlight relay kits to help reduce some of the load on the alternator when the lights are on. Rob makes a nice kit that plugs into your existing harness but I wanted to eliminate some of the excess wiring that is left when you install the kit. The old harness had seen better days so it was taken out to be freshened up. The unnecessary wires were removed and the whole thing was re-wrapped.

So yeah, things are looking better. Having the car ready for Mopars at the Valley this weekend is out the window but I'm still holding out hope I can get it down the track this year. I'm confident I will be able to drive it soon but realistically, there may not be enough time before winter to get it sorted out. We'll see.

More to come.