Slacker's Guide to Fixing Up the 68 Notch

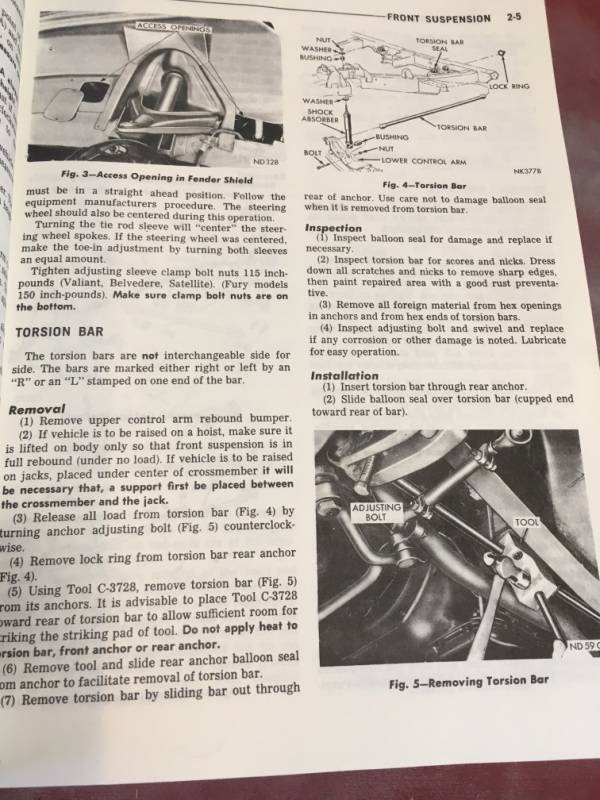

I started work on removing the right side front suspension, specifically the torsion bar today. I have not done suspension work myself other than replacing shocks, so I am mostly following the factory service manual to guide me. I purchased a reproduction FSM several years ago. I always like how the Chrysler manuals refer to a special tool for the job (such as "Tool C-3728" in the pic) - I always wondered if the dealer mechanics always had these tools available to them.

Just a reference picture showing where the torsion bar anchors in the front to the lower control arm.

The first step was to remove the tension off the torsion bar. Sprayed a little WD-40 on the adjustment bolt then loosened it all the way with a 3/4 inch socket. The bolt is sandwiched within the lower control arm.

Got the bolt completely backed out and tension completely off the TB.

Another reference picture showing where the torsion bar anchors in the rear (to the frame). It was really built up with grease, dirt, and possibly a little undercoating. I needed to clean that up a little and remove a lock ring to allow the TB to be removed towards the rear.

Well I scraped some of the crud out with a screwdriver better exposing the lock ring. The ring came out easily with a pair of needle nose pliers.

This little wimpy clip is what keeps your torsion bar in! Well it has served very honorably for 48 years! The picture does make it look much more stout that actual - it is really a wimpy little pin. I am sure the TB tension and loaded suspension helps keep the TB it in place too.

This is the torsion bar removal tool out of my American Muscle kit. Lets see if it works.

Got the tool installed on the torsion bar. A little crowded by the header, but I had enough room to get some whacks on it. The TB comes needs to come out towards the back of the car, through the rear anchor plate, so I hammered the tool towards the rear.

After some persuasion with a 1.5 lb deadblow hammer on the removal tool the TB freed itself from the front anchor on the lower control arm.

Once the TB was free of the front anchor on the LCA, I removed the rubber boot by sliding it from the rear of the TB to the front.

What a 48 year old TB grease boot looks like.

This pic shows where I had the TB almost completely slid out except for going through the rear anchor. I was able to pull it by hand to this point, then apparently my manly arms showed signs of being like some old guy. Oops, keep forgetting I am an old guy. Anyway I don't have a picture, but I just relocated the bitchin removal tool to this back side and gave it a few whacks to finish removing the TB. By the way that rotted pipe looking thing under the torsion bar is not my driveshaft, it is an header muffler, probably a Thrush if I recall correctly.

Rear of TB. From research on FABO this 892 part number corresponds to a .870 diameter TB's that were used on 340 cars and 318's with AC. Haven't decided whether I will keep these or go with something heavier. Looking for some advice on this matter.

Front of TB. I referenced marked both ends in grease pencil.

So I need to scrape some crud off and put it away for potential future reinstall. Now I need to work on the removing the rest of the front suspension components on this right side.

I see I caught that blue LED light in the top of this pic. Those are those freebie lights you get at Harbor Freight when you buy something. I think I have 3 of those now and actually think they are pretty handy and durable.

I started work on removing the right side front suspension, specifically the torsion bar today. I have not done suspension work myself other than replacing shocks, so I am mostly following the factory service manual to guide me. I purchased a reproduction FSM several years ago. I always like how the Chrysler manuals refer to a special tool for the job (such as "Tool C-3728" in the pic) - I always wondered if the dealer mechanics always had these tools available to them.

Just a reference picture showing where the torsion bar anchors in the front to the lower control arm.

The first step was to remove the tension off the torsion bar. Sprayed a little WD-40 on the adjustment bolt then loosened it all the way with a 3/4 inch socket. The bolt is sandwiched within the lower control arm.

Got the bolt completely backed out and tension completely off the TB.

Another reference picture showing where the torsion bar anchors in the rear (to the frame). It was really built up with grease, dirt, and possibly a little undercoating. I needed to clean that up a little and remove a lock ring to allow the TB to be removed towards the rear.

Well I scraped some of the crud out with a screwdriver better exposing the lock ring. The ring came out easily with a pair of needle nose pliers.

This little wimpy clip is what keeps your torsion bar in! Well it has served very honorably for 48 years! The picture does make it look much more stout that actual - it is really a wimpy little pin. I am sure the TB tension and loaded suspension helps keep the TB it in place too.

This is the torsion bar removal tool out of my American Muscle kit. Lets see if it works.

Got the tool installed on the torsion bar. A little crowded by the header, but I had enough room to get some whacks on it. The TB comes needs to come out towards the back of the car, through the rear anchor plate, so I hammered the tool towards the rear.

After some persuasion with a 1.5 lb deadblow hammer on the removal tool the TB freed itself from the front anchor on the lower control arm.

Once the TB was free of the front anchor on the LCA, I removed the rubber boot by sliding it from the rear of the TB to the front.

What a 48 year old TB grease boot looks like.

This pic shows where I had the TB almost completely slid out except for going through the rear anchor. I was able to pull it by hand to this point, then apparently my manly arms showed signs of being like some old guy. Oops, keep forgetting I am an old guy. Anyway I don't have a picture, but I just relocated the bitchin removal tool to this back side and gave it a few whacks to finish removing the TB. By the way that rotted pipe looking thing under the torsion bar is not my driveshaft, it is an header muffler, probably a Thrush if I recall correctly.

Rear of TB. From research on FABO this 892 part number corresponds to a .870 diameter TB's that were used on 340 cars and 318's with AC. Haven't decided whether I will keep these or go with something heavier. Looking for some advice on this matter.

Front of TB. I referenced marked both ends in grease pencil.

So I need to scrape some crud off and put it away for potential future reinstall. Now I need to work on the removing the rest of the front suspension components on this right side.

I see I caught that blue LED light in the top of this pic. Those are those freebie lights you get at Harbor Freight when you buy something. I think I have 3 of those now and actually think they are pretty handy and durable.