Trevor B

Well-Known Member

Are any of you folks engineers or physicists? Or smart in such things? I am not.

The garage I rent has lots of storage up top but no way to get anything there... just a ladder!

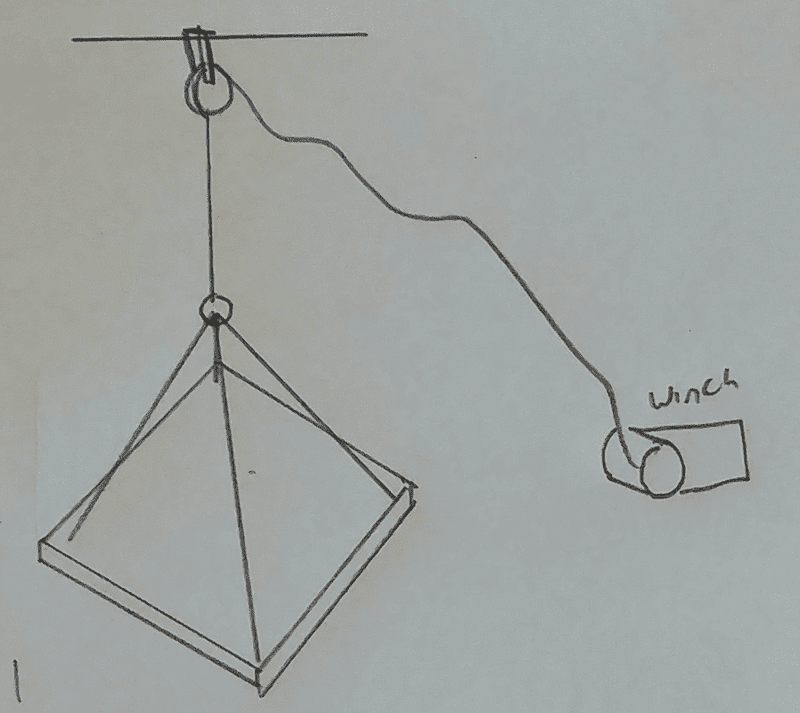

I need a plan to construct a small winch-operated elevator or the like: raise a wooden pallet/platform straight upward using an electric winch. Ideally simple and inexpensive - Harbor Freight has electric winches with 35' of cable for cheap.

This would not be used for really heavy items like engine blocks but I'd love to get the bulky stuff off the floor - extra wheels/tires, etc - without having to carry each item up the ladder in my teeth or some such.

I have the feeling that my simple plan may not be stable enough:

The garage I rent has lots of storage up top but no way to get anything there... just a ladder!

I need a plan to construct a small winch-operated elevator or the like: raise a wooden pallet/platform straight upward using an electric winch. Ideally simple and inexpensive - Harbor Freight has electric winches with 35' of cable for cheap.

This would not be used for really heavy items like engine blocks but I'd love to get the bulky stuff off the floor - extra wheels/tires, etc - without having to carry each item up the ladder in my teeth or some such.

I have the feeling that my simple plan may not be stable enough: