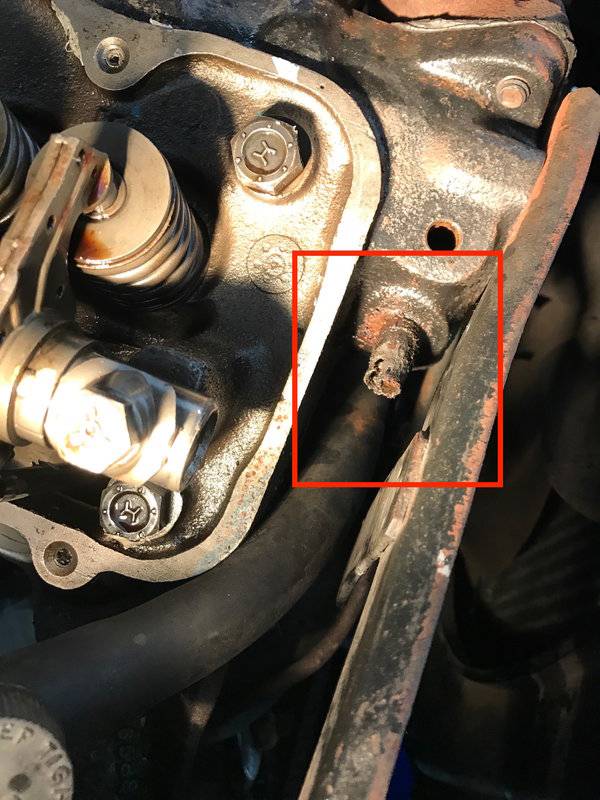

The "how to' article I looked at uses a hacksaw in a larger I.D. fitting. I don't think you'll get a standard hacksaw blade in this one. What I would try... First, remove the accessory bracket for greater access. BP blaster or similar solvent. Place a piece of material inside the fitting, round, hex, even square can work. This allows a little crushing but prevents total collapse. Place the smallest pipe wrench or round jaw vise grip flat square close as possible. When we're lucky the fitting will back out. When we aren't so lucky... We cut it away flush to the casting then drill and re tap as slantsixdan stated. Good luck