MRL 340 for the 21st Century

MRL 340 for the 21st Century

I posted a poll a while back asking how You would like to see a 340 built. Options were 1) Keep it a 340, 2) Mid level stroke- less than 4.00”, 3) Big stroke- 4.00” or more. It was 2 to 1 to keep it a 340. That’s what I’m doing. I’m going to put MY MONEY where my mouth is and show the whole Mopar community what a well thought out, well machined, well-engineered 340 can do.

Is it going to be trick? Why yes, yes it is.

Is it going to be Exotic? No, not at all.

Most everything is off the shelf parts, albeit with some tweaks, but nothing One Off and Exotic. Something that you can fit under the hood and bolt up into your car without a lot of custom work. Unlike some of these super high end dyno challenge engines with all their super fancy dry sumps, super fancy and complicated ignition systems, intakes and spacers that are so over the top ridiculous that they would never fit into your car without having to do some serious modifications. None of that here. With that being said, this will be a very strong running 340 but not a full on, total race/dyno monster. The goal is to make a 340 that will make 550HP at 6500rpm. That’s the goal. 6500rpm in a 340 is a reasonable speed and wont put a lot of wear and tear on the engine. Will it peak there? Maybe not.

Some stuff is pretty basic, some stuff is not. The one big thing that is wrong and always has been wrong with the 340 is the weight of the rotating assembly. It heavy, and not by a little. Its VERY heavy, more than some aftermarket BBM stroker stuff. That’s bad and it causes stress and loss of power. Another thing I don’t like is the area Above the piston pin, its too much(like a 440). Too much area above the pin causes the piston to rock an excessive amount, this puts the rings in a bad position to seal well and it tends to load the wall a bit more than it should when changing direction. So enough of all That. Lets get to the real meat and the test.

The Meat.

340 block 4.080 bore

Forged 340 crank

Flat top piston .927 wrist pin

6.250 I beam rods 2.100 pin size

.043/.043/3mm ring pack

RPM heads full CNC porting

RPM intake, some porting

1.6 roller rockers

MRL/BAM roller lifters

Comp cam 248/254 .575/.585

9.8 to 1 PUMP GAS

FiTech EFI with total timing control

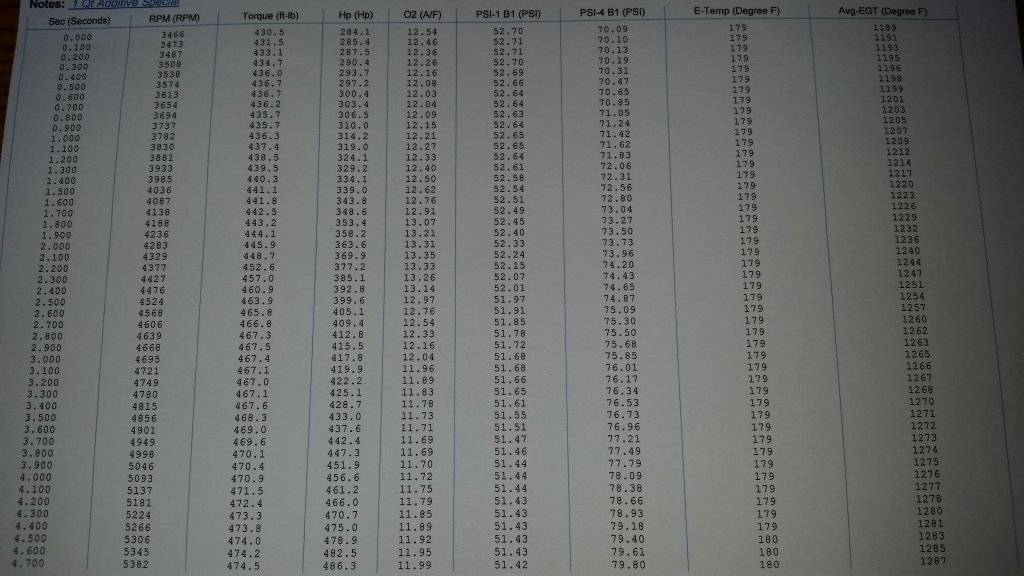

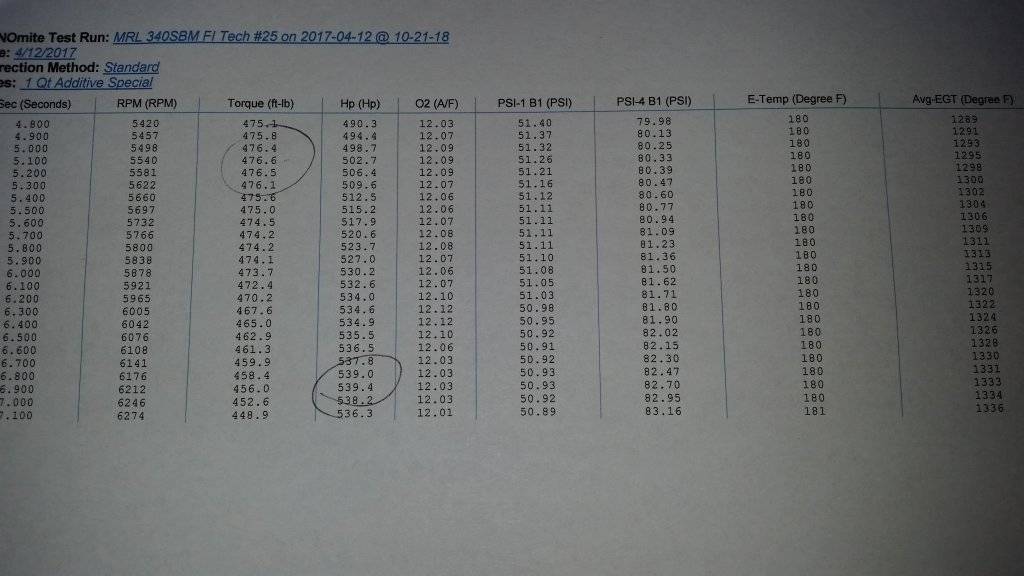

So what did it do? Did we hit our goal? Well, not quite but close.

It made a total of 539.4HP at 6200rpm and 476.6TQ at 5550rpm

The real story is the “Curve”. It made 460TQ from 4450 to 6150rpm and 500+HP from 5500rpm on up.

It idled at 950rpm pulling 10in vacuum, has a nice lope, but not too much. Runs very smooth all the way thru the RPM range. So a 340, NON STROKER Street engine on pump gas making 1.56HP Per CI. That’s a BIG WINNER in my book.

Pics soon, I still have to paint it. Enjoy the dyno sheets.

MRL 340 for the 21st Century

I posted a poll a while back asking how You would like to see a 340 built. Options were 1) Keep it a 340, 2) Mid level stroke- less than 4.00”, 3) Big stroke- 4.00” or more. It was 2 to 1 to keep it a 340. That’s what I’m doing. I’m going to put MY MONEY where my mouth is and show the whole Mopar community what a well thought out, well machined, well-engineered 340 can do.

Is it going to be trick? Why yes, yes it is.

Is it going to be Exotic? No, not at all.

Most everything is off the shelf parts, albeit with some tweaks, but nothing One Off and Exotic. Something that you can fit under the hood and bolt up into your car without a lot of custom work. Unlike some of these super high end dyno challenge engines with all their super fancy dry sumps, super fancy and complicated ignition systems, intakes and spacers that are so over the top ridiculous that they would never fit into your car without having to do some serious modifications. None of that here. With that being said, this will be a very strong running 340 but not a full on, total race/dyno monster. The goal is to make a 340 that will make 550HP at 6500rpm. That’s the goal. 6500rpm in a 340 is a reasonable speed and wont put a lot of wear and tear on the engine. Will it peak there? Maybe not.

Some stuff is pretty basic, some stuff is not. The one big thing that is wrong and always has been wrong with the 340 is the weight of the rotating assembly. It heavy, and not by a little. Its VERY heavy, more than some aftermarket BBM stroker stuff. That’s bad and it causes stress and loss of power. Another thing I don’t like is the area Above the piston pin, its too much(like a 440). Too much area above the pin causes the piston to rock an excessive amount, this puts the rings in a bad position to seal well and it tends to load the wall a bit more than it should when changing direction. So enough of all That. Lets get to the real meat and the test.

The Meat.

340 block 4.080 bore

Forged 340 crank

Flat top piston .927 wrist pin

6.250 I beam rods 2.100 pin size

.043/.043/3mm ring pack

RPM heads full CNC porting

RPM intake, some porting

1.6 roller rockers

MRL/BAM roller lifters

Comp cam 248/254 .575/.585

9.8 to 1 PUMP GAS

FiTech EFI with total timing control

So what did it do? Did we hit our goal? Well, not quite but close.

It made a total of 539.4HP at 6200rpm and 476.6TQ at 5550rpm

The real story is the “Curve”. It made 460TQ from 4450 to 6150rpm and 500+HP from 5500rpm on up.

It idled at 950rpm pulling 10in vacuum, has a nice lope, but not too much. Runs very smooth all the way thru the RPM range. So a 340, NON STROKER Street engine on pump gas making 1.56HP Per CI. That’s a BIG WINNER in my book.

Pics soon, I still have to paint it. Enjoy the dyno sheets.