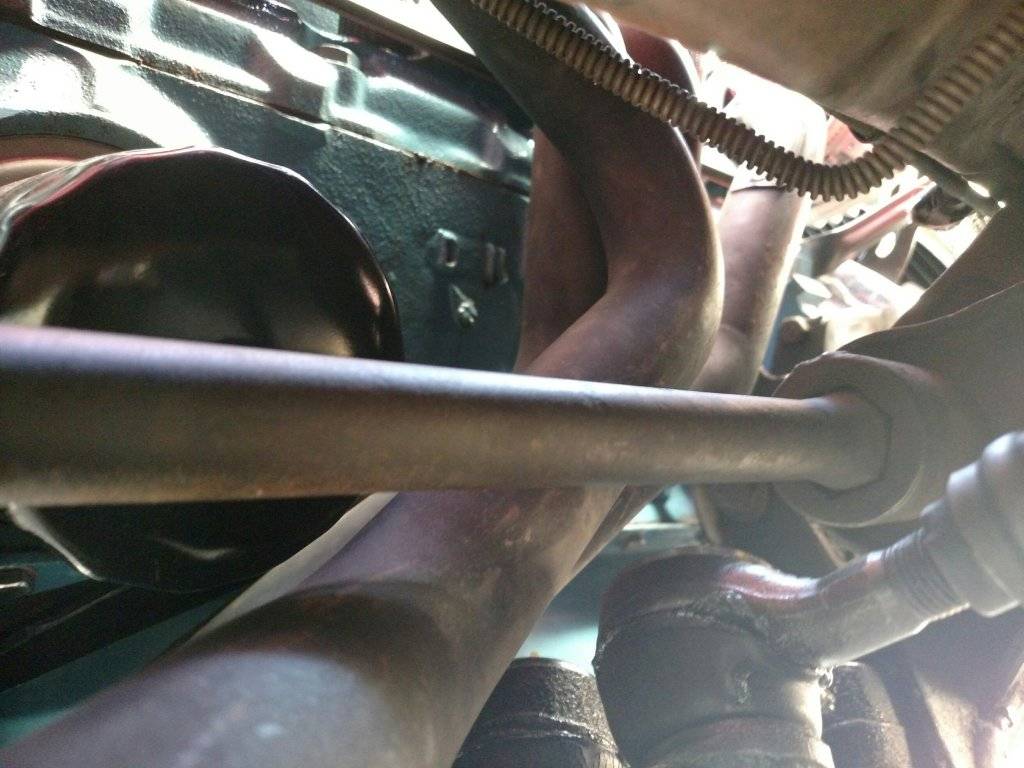

I made a post about 2 weeks ago about getting the correct motor mounts, and thanks to you guys the engine is sitting perfect in the car. I have returned for more help. I reached a wall with these headers, the right side header simply doesn't fit. No matter how high I jack the car up, or how I angle the header, its just not happening. Now I know I should have bought the TTIs or Dougs or anything other than these, but I'm 18 years old and those are not an option for me. Now, I figured the drivers side would have been worse because of the power steering and giant 500 pound starter, but no. That side was on in like ten minutes. I didn't even have to jack the car up that much. The instructions say for both sides that they go in from the bottom up, but on the left side one pipe is blocked by this bar running under the car. Now forgive me I have no idea what this thing is called, but it doesn't look like its suppose to come out. The car is currently jacked up 37 inches in the front. All jacks are maxed out, I even tried using wooden blocks for more height and almost crushed myself under the car when they gave out. Any help with this would be greatly appreciated, and later on I'll just make a build post if anyone is interested. Here is some pictures of the rod in the way. Kinda hard to see from the bottom view.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

74 Dart Sport. Hedman Header Hell.

- Thread starter SharpDJS

- Start date

-

73Swinger18

✱ⓈⓌⒾⓃⒼⒺⓇ

That's your torsion bar, part of your suspension. You need to remove the engine mount bolt, then place a piece of wood between your oil pan and jack to carefully lift the engine up while the car rests elevated on the stands. Once you raise the engine a few inches, they will fit easily. You may need to remove items like your radiator shroud to prevent the engine from getting jammed while jacking it.

Lustle

Well-Known Member

What hedmans you using?

I have a 72 car but with a 73+ k member. For disc breaks. I have power steering and brakes. And I got my hookers to fit. They are the "too low, drag, don't fit right, have to disconnect the steering" pain the *** headers that everyone here loves to hate. But they were 200 bucks.

To get mine in the passenger side was easy. The drivers side was a pain in my ***.

You mention you have the car jacked up. But have you jacked the engine up? Here's what you do. Disconnect the motor mounts. Should be spool type. With the car low enough that you can put a floor jack under the oil pan and still jack it up. You MUST put a piece of wood between the jack and oil pan. And this piece of wood MUST extend past the sides of the pan. This way you are putting stress on the wall/sides of the pan. Not just on one small hole in the center. Which will surely fail. Then jack the engine up. You can probably get between 4-6 inches without having to disconnect anything else (watch the distributor cap though. It gets awful close to the firewall). I think I got close to 6 out of mine. This will give you MORE than enough room to fit everything through. Mine went in through the top fine like this.

Now. That's assuming you're using the cheapy below the steering linkage setup headers like I did. If they are another type. All bets are off.

I have a 72 car but with a 73+ k member. For disc breaks. I have power steering and brakes. And I got my hookers to fit. They are the "too low, drag, don't fit right, have to disconnect the steering" pain the *** headers that everyone here loves to hate. But they were 200 bucks.

To get mine in the passenger side was easy. The drivers side was a pain in my ***.

You mention you have the car jacked up. But have you jacked the engine up? Here's what you do. Disconnect the motor mounts. Should be spool type. With the car low enough that you can put a floor jack under the oil pan and still jack it up. You MUST put a piece of wood between the jack and oil pan. And this piece of wood MUST extend past the sides of the pan. This way you are putting stress on the wall/sides of the pan. Not just on one small hole in the center. Which will surely fail. Then jack the engine up. You can probably get between 4-6 inches without having to disconnect anything else (watch the distributor cap though. It gets awful close to the firewall). I think I got close to 6 out of mine. This will give you MORE than enough room to fit everything through. Mine went in through the top fine like this.

Now. That's assuming you're using the cheapy below the steering linkage setup headers like I did. If they are another type. All bets are off.

73Swinger18

✱ⓈⓌⒾⓃⒼⒺⓇ

A few lessons learned... Use sealant on the most fwd/aft header bolts to prevent coolant leaks. You may also want to get a mini starter and put it in now to prevent the removal of the header again when the big one fails. You can pull a mini out without removing the header. The '95 Dakota starter is pretty cheap from NAPA, PN: RAY 2446415.

nm9stheham

Well-Known Member

I know this will not help the OP with this issue but ya know what I like most about this thread?

AN 18 Y.O. PUTTING IN HIS OWN HEADERS!!! That is just awesome...!!

Man, be careful under there..... I have dodged falling cars 2x in my life and feel lucky to have seen it start going just in time to roll out. Dang....

AN 18 Y.O. PUTTING IN HIS OWN HEADERS!!! That is just awesome...!!

Man, be careful under there..... I have dodged falling cars 2x in my life and feel lucky to have seen it start going just in time to roll out. Dang....

Punisher66j

Dart Swinger

I had no luck with my 74 swinger with the 230ish pair of headers. No matter what I did the passenger side hit the knuckles of the tie rods when you turned the wheel. I would have to cut the pipe out and re-bend a new one to make it work.

I've already tried jacking up the motor as much as possible, I even tried the leave one mount bolt method listed above. None gave enough room for the headers. I just took some more pictures and I'll list the part number in a few mins.What hedmans you using?

I have a 72 car but with a 73+ k member. For disc breaks. I have power steering and brakes. And I got my hookers to fit. They are the "too low, drag, don't fit right, have to disconnect the steering" pain the *** headers that everyone here loves to hate. But they were 200 bucks.

To get mine in the passenger side was easy. The drivers side was a pain in my ***.

You mention you have the car jacked up. But have you jacked the engine up? Here's what you do. Disconnect the motor mounts. Should be spool type. With the car low enough that you can put a floor jack under the oil pan and still jack it up. You MUST put a piece of wood between the jack and oil pan. And this piece of wood MUST extend past the sides of the pan. This way you are putting stress on the wall/sides of the pan. Not just on one small hole in the center. Which will surely fail. Then jack the engine up. You can probably get between 4-6 inches without having to disconnect anything else (watch the distributor cap though. It gets awful close to the firewall). I think I got close to 6 out of mine. This will give you MORE than enough room to fit everything through. Mine went in through the top fine like this.

Now. That's assuming you're using the cheapy below the steering linkage setup headers like I did. If they are another type. All bets are off.

Lustle

Well-Known Member

Will they not go in from the top?

If I recall my passenger side took a little twisty/turny to get in from the top.

If I recall my passenger side took a little twisty/turny to get in from the top.

I'll also like to commend the OP for taking on the challenge. Good for you, my young friend! Why that bullshit company purposely MIS spells "Header" is beyond me...

I has a set of the # 78050 headers that were supposed to fit 67-76 318 A body cars. The car was a 73 Dart Sport with a non original 360. Now, despite what some may think, I am no idiot...I have been messing with cars since 1983. I know the tricks to get headers to fit in a Mopar as long as they are built right.

The set I had were crap. The right side collector wanted to share space with the torsion bar. I removed the torsion bar to get them in and a couple of tubes then wanted to hit the STOCK oil pan even though there was still a small gap at the bottom of the head mounting flange...In other words, I'd have to run NO oil pan to get the headers to swing in enough for the flange to sit flat against the head....AND it still interfered with the torsion bar. They were not altered, damaged or dented. They looked fresh from the company. I usually get the right side in first then install the left. This one sucked so bad I just gave up and GAVE them away at a swap meet. The guy was amazed and felt like he really scored.

He did NOT score. He stepped in a soft pile of crap.

I told him they didn't fit but he seemed oblivious, as if I were some idiot and HE knew all the answers.

I has a set of the # 78050 headers that were supposed to fit 67-76 318 A body cars. The car was a 73 Dart Sport with a non original 360. Now, despite what some may think, I am no idiot...I have been messing with cars since 1983. I know the tricks to get headers to fit in a Mopar as long as they are built right.

The set I had were crap. The right side collector wanted to share space with the torsion bar. I removed the torsion bar to get them in and a couple of tubes then wanted to hit the STOCK oil pan even though there was still a small gap at the bottom of the head mounting flange...In other words, I'd have to run NO oil pan to get the headers to swing in enough for the flange to sit flat against the head....AND it still interfered with the torsion bar. They were not altered, damaged or dented. They looked fresh from the company. I usually get the right side in first then install the left. This one sucked so bad I just gave up and GAVE them away at a swap meet. The guy was amazed and felt like he really scored.

He did NOT score. He stepped in a soft pile of crap.

I told him they didn't fit but he seemed oblivious, as if I were some idiot and HE knew all the answers.

Subscribed

I really wanna see the OP succeed on this.

Now this needs all caps...

BE CAREFUL UNDER THERE!!!!!!!!

Sorry for yelling....needs to be said...

Jeff

I really wanna see the OP succeed on this.

Now this needs all caps...

BE CAREFUL UNDER THERE!!!!!!!!

Sorry for yelling....needs to be said...

Jeff

AJ/FormS

68 Formua-S fastback clone 367/A833/GVod/3.55s

- Joined

- Jan 19, 2014

- Messages

- 24,900

- Reaction score

- 12,255

I guess you don't know how easy it is to move that darn T-bar.

With the T-bar out of the way, And the oil filter off. My TTI goes up from the bottom like nothing.

With the T-bar out of the way, And the oil filter off. My TTI goes up from the bottom like nothing.

73Swinger18

✱ⓈⓌⒾⓃⒼⒺⓇ

Did you remove the oil filter and try installing it from the top? I have those exact same headers and the passenger side had a lot more room than the driver's on mine.

MOPAROFFICIAL

Oogliboogli

Remove oil filter, adapter if equipt....and take the motor bracket off , take loose the driver side at the biscuit/k frame,lift up motor so it can move forward enough to clear the t bar.

340 demon 72

Well-Known Member

remove torsion bar and will slip right in piece circled in red

![0419171911[1] - Copy.jpg 0419171911[1] - Copy.jpg](https://www.forabodiesonly.com/mopar/attachments/0419171911-1-copy-jpg.1715040326/)

Does OP know how to remove the torsion bar?

Jeff

Jeff

No I tried, but the won't.Will they not go in from the top?

If I recall my passenger side took a little twisty/turny to get in from the top.

I have no ideaDoes OP know how to remove the torsion bar?

Jeff

73Swinger18

✱ⓈⓌⒾⓃⒼⒺⓇ

You don't need to remove the torsion bar. I have the same ones and if the filter is off, the eng/trans brace removed, and engine lifted, it will fit. Here are some pictures of mine if it helps. As you can see, it's tight.

MOPAROFFICIAL

Oogliboogli

My god, leave the t bar in...some of you guys..lol

64physhy

Well-Known Member

Like others have said: remove the oil filter. I it has a 90 degree adapter, that needs to come off, too. Jack the engine up about 2 or 3 inches, and it should go in. If not, you'll probably have to take the torsion bar off (not that difficult). When you jack up the engine, be sure to keep an eye on the left side to make sure the other header doesn't hit anything.

Lustle

Well-Known Member

Is the oil filter not removed?

Looks like just the plate in the block boss there to me.

Looks like just the plate in the block boss there to me.

I removed the filter, and that brace, I guess all I can do is jack the thing up even higher than before, starts getting pretty sketchy once I go past a certain point though.You don't need to remove the torsion bar. I have the same ones and if the filter is off, the eng/trans brace removed, and engine lifted, it will fit. Here are some pictures of mine if it helps. As you can see, it's tight.

View attachment 1715040340 View attachment 1715040341 View attachment 1715040342

-