Hey Jason, this is Jake. I just saw this thread and read the whole thing- very impressive. I don't know how I've missed it- I look at this site all the time. I will have to come up there and check it out. Maybe some of your skills will rub off on me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1969 DART CUSTOM FULL RESTORATION

- Thread starter CrOoKs

- Start date

-

Howd you clean up that center section?

Evapo-Rust and a wire brush or wheel. Evapo-Rust is great stuff!

CrOoKs

Well-Known Member

Howd you clean up that center section?

Like FJ5 Duster said.....I sat it over a bucket on two blocks of wood and sprayed a rust remover on it (keeping it wet) and scrubbed it with a wire brush over a period of about an hour

Last edited:

CrOoKs

Well-Known Member

Hey Jason, this is Jake. I just saw this thread and read the whole thing- very impressive. I don't know how I've missed it- I look at this site all the time. I will have to come up there and check it out. Maybe some of your skills will rub off on me.

Hey Jake glad to see you on here! Come on up!

So impressive! You're halfway to a brand new car!

With all your skills and up to 700hp are you considering adding any frame strengthening measures?: sub-frame connectors, torque boxes, reinforcing the front frame rails, etc.?

Are you keep the stock from suspension?

With all your skills and up to 700hp are you considering adding any frame strengthening measures?: sub-frame connectors, torque boxes, reinforcing the front frame rails, etc.?

Are you keep the stock from suspension?

CrOoKs

Well-Known Member

So impressive! You're halfway to a brand new car!

With all your skills and up to 700hp are you considering adding any frame strengthening measures?: sub-frame connectors, torque boxes, reinforcing the front frame rails, etc.?

Are you keep the stock from suspension?

I've already installed the US Cartool sub-frame connectors and also did larger and more spot welds than the factory throughout the restoration. I have contemplated torque boxes and possibly braces from the sub-frame to the rockers. It will not be a drag car but I do not want it twisting and cracking. It's honestly probably going to be a 500-550hp car with intentions of building a 500" stroker later.

Thank you!

moparmat2000

Well-Known Member

You got skillz there CrOoKs

Nice buildup. I replaced my trans crossmember and main floorpan and thought that was a lot of work. You did a whole lot more. I am impressed. Lots of good sheetmetal tips for the rest of us. I love the panel flanger idea. I bought one years ago, never had the opportunity to use it yet. I will be using it on my barracuda rear quarters. I patched mine initally but was able to get goodmark rear panels pretty inexpensively so off they will come to be replaced.

I'd recommend like some others to get cleco pins. Brown aviation tool supply www.browntool.com has them. About $4.20 a dozen for spring type (button top). Plyers are about $6.00. They also have "draw clecos" (wingnut type) those are about $2.95 each. I have bunch of each style. I use the #40 clecos with a 3/32" drill. These come in handy and make welding up such a small hole real easy. I usually drill to fit, then pull the pieces back apart and remove the burrs around the holes then reassemble so the pieces fit tight before welding. If the 3/32" drill is too small you can get #30 which use an 1/8" drill.

Anyway, i am subscribed. Your build has given me renewed enthusiasm for mine I have 3 kiddos left out of 4. Oldest is 18 and getting ready to fly the coop, youngest is 4&1/2. As soon as i can get back into it i will be gittin er dun.

Matt

Nice buildup. I replaced my trans crossmember and main floorpan and thought that was a lot of work. You did a whole lot more. I am impressed. Lots of good sheetmetal tips for the rest of us. I love the panel flanger idea. I bought one years ago, never had the opportunity to use it yet. I will be using it on my barracuda rear quarters. I patched mine initally but was able to get goodmark rear panels pretty inexpensively so off they will come to be replaced.

I'd recommend like some others to get cleco pins. Brown aviation tool supply www.browntool.com has them. About $4.20 a dozen for spring type (button top). Plyers are about $6.00. They also have "draw clecos" (wingnut type) those are about $2.95 each. I have bunch of each style. I use the #40 clecos with a 3/32" drill. These come in handy and make welding up such a small hole real easy. I usually drill to fit, then pull the pieces back apart and remove the burrs around the holes then reassemble so the pieces fit tight before welding. If the 3/32" drill is too small you can get #30 which use an 1/8" drill.

Anyway, i am subscribed. Your build has given me renewed enthusiasm for mine I have 3 kiddos left out of 4. Oldest is 18 and getting ready to fly the coop, youngest is 4&1/2. As soon as i can get back into it i will be gittin er dun.

Matt

I just talked with Crooks last night... He is still making great headway on the Dart! I think he has just been too busy to post. Also after talking with him last night I found out the Dart will be getting some awesome upgrades that I'm sure he will post about when ready. Trust me this car is going to be killer!

Last edited:

moparmat2000

Well-Known Member

I need to start a thread on mine, however its so slow going that people will get bored with no progress.

CrOoKs

Well-Known Member

You got skillz there CrOoKs

Nice buildup. I replaced my trans crossmember and main floorpan and thought that was a lot of work. You did a whole lot more. I am impressed. Lots of good sheetmetal tips for the rest of us. I love the panel flanger idea. I bought one years ago, never had the opportunity to use it yet. I will be using it on my barracuda rear quarters. I patched mine initally but was able to get goodmark rear panels pretty inexpensively so off they will come to be replaced.

I'd recommend like some others to get cleco pins. Brown aviation tool supply www.browntool.com has them. About $4.20 a dozen for spring type (button top). Plyers are about $6.00. They also have "draw clecos" (wingnut type) those are about $2.95 each. I have bunch of each style. I use the #40 clecos with a 3/32" drill. These come in handy and make welding up such a small hole real easy. I usually drill to fit, then pull the pieces back apart and remove the burrs around the holes then reassemble so the pieces fit tight before welding. If the 3/32" drill is too small you can get #30 which use an 1/8" drill.

Anyway, i am subscribed. Your build has given me renewed enthusiasm for mine I have 3 kiddos left out of 4. Oldest is 18 and getting ready to fly the coop, youngest is 4&1/2. As soon as i can get back into it i will be gittin er dun.

Matt

Thank you very much Matt! I appreciate your cleco info as well sir! This has definitely been a huge undertaking and I have done way more than I originally planned but it'll all be worth it in the end!!

CrOoKs

Well-Known Member

I did make a little progress Friday and got the rear deck panel, driver side trunk hinge and couple other things welded up.

I cannot remember if I posted pics of my caltracs but I did end up getting them and going to use sliders instead of shackles.

Thank you all for following the build and I'm sorry life has gotten busy the last month but I'm planning on hitting it hard again soon.

I cannot remember if I posted pics of my caltracs but I did end up getting them and going to use sliders instead of shackles.

Thank you all for following the build and I'm sorry life has gotten busy the last month but I'm planning on hitting it hard again soon.

CrOoKs

Well-Known Member

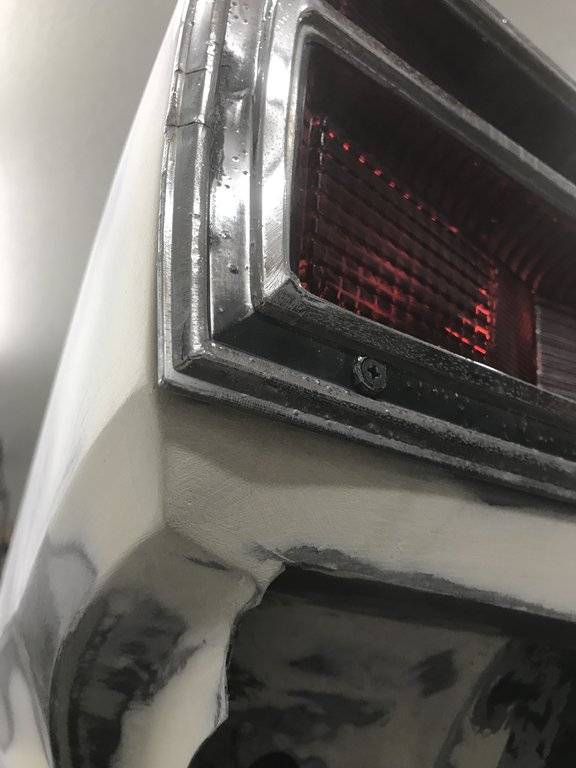

Spent the last couple days muddin the top edge of the drivers quarter and rear deck panel. Also, got the quarter reshaped to the tail light.

CrOoKs

Well-Known Member

I also cleaned up the lower corners of the rear window, epoxy coated them and then spread 3m 08115 panel bond on them to help prevent them from ever rusting again. I did the same thing on the outer wheel well and wheel opening lip to help prevent rust around the wheel opening. Basically any place that could hold dirt has a skim coat of panel bond on it.

CrOoKs

Well-Known Member

Got the roof stripped today. I will be treating the pitted area with a rust remover that leaves a zinc phosphate coating. I am not putting a vinyl top back on it.

Evan Dutch

Well-Known Member

What product are you using?

CrOoKs

Well-Known Member

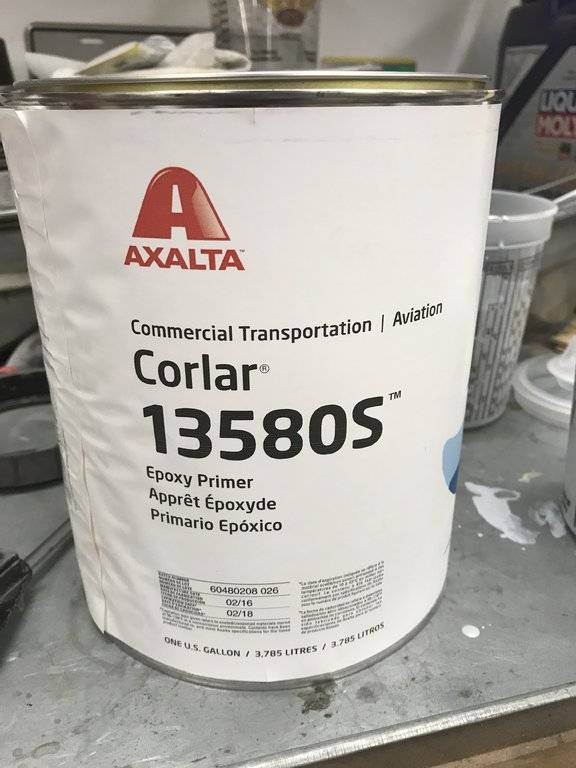

I spent 5 hours Thursday night removing the rust from the pitted areas. Today I cleaned the roof off, applied epoxy to the pitted areas then did the body work. I wanted to get some primer on the roof and drivers side before things started to surface rust due to the humidity so I had a buddy swing by and lay down two coats of the best aviation grade epoxy/high build primer out there. The stuff will flow out over night and leaves a gloss finish. It's expensive at $280/gal with activator but is well worth it in the end.

At this point I just have to finish up the passenger side quarter panel, the front a pillars, cowl, hood and trunk lid and it'll be ready to block, reprime then wet block! Hoping to have it in final primer and block by the end of the month!

At this point I just have to finish up the passenger side quarter panel, the front a pillars, cowl, hood and trunk lid and it'll be ready to block, reprime then wet block! Hoping to have it in final primer and block by the end of the month!

CrOoKs

Well-Known Member

What product are you using?

SEM product called Rust-Mort

CrOoKs

Well-Known Member

Got the top edge of the passenger quarter straightened today. My goal is to finish the quarter/rocker and front cowl and hope to have the shell in primer by Saturday night. That will leave the trunk and hood left to block and get straight which shouldn't take much work.

CrOoKs

Well-Known Member

Put the family to bed and headed to the shop at 9:00 tonight! I am determined to get this in the first stage of primer this weekend. I have the quarter about 95% done. Still need to touch up the tail light area and door gap then mud the rocker in. Hoping to get home from work a tad early tomorrow and finish the passenger side up.

69DartMatt

Well-Known Member

Where is your rotisserie bolted to on the car? I assume for the front its to the frame where the bumper brackets bolt to, but on the rear is it to the bumper bracket bolts or the frame somewhere? I built a rotisserie a couple of months ago and for the rear I made brackets to bolt to the bumper bolts. Now I'm wondering if that area is strong enough to support the weight of the car on the rotisserie without twisting that panel. Here is my rotisserie for the rear brackets to mount my car.

Also, where did you pick up the aviation primer? Local or order it online?

By the way, the car is coming together nicely! I wish mine was closer so I could work on it as much as I could. The body work would be at about the same stage as yours is if I could work on it everyday.

Keep up the great work man!

Also, where did you pick up the aviation primer? Local or order it online?

By the way, the car is coming together nicely! I wish mine was closer so I could work on it as much as I could. The body work would be at about the same stage as yours is if I could work on it everyday.

Keep up the great work man!

Last edited:

69DartMatt,

We bolted the rotisserie up to the bumper mounting points and it has worked fine. My 71 Challenger, 70 Duster and my brothers 68 Super Bee were on that same rotisserie mounted the same way. Never had any issues with any of those cars on it.

We bolted the rotisserie up to the bumper mounting points and it has worked fine. My 71 Challenger, 70 Duster and my brothers 68 Super Bee were on that same rotisserie mounted the same way. Never had any issues with any of those cars on it.

CrOoKs

Well-Known Member

Finally got the entire passenger side done tonight! Going to get up in the morning and work on the a-pillars and cowl then get primer on it. I'm beat but I want it in primer this weekend. It'll be a huge accomplishment!

/72Scamp

Well-Known Member

Cars coming along amazing! Keep up the good work

Looks great Jason! Are you going to the car cruise tonight depending on the weather? Brody and I plan on being there around 6.

-