Daves69

Well-Known Member

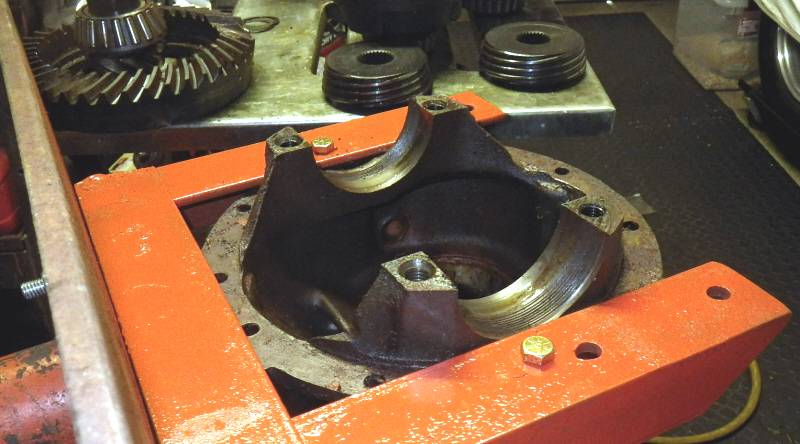

Opened up the old 489 (broken 5.13) to see what is needed to make a good one.

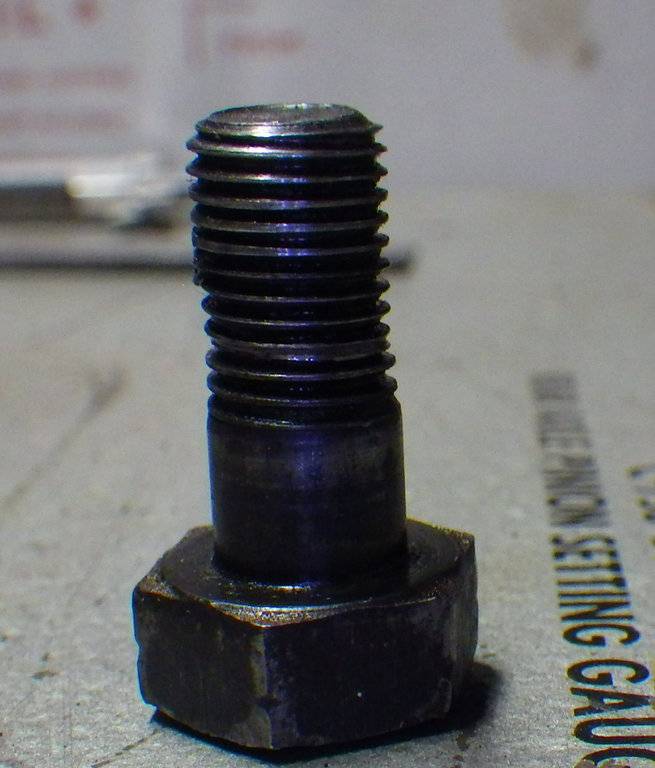

Had a bit of trouble with the ring gear bolt removal as they had some (Lol) "offset" to them.

But "I think" I'm good on the SG. All the internal gears look good. Splines look good. The cones look good as well and I see no signs of any bottoming. I can see the tooling marks in the bottom.......

What's your opinions on this sure grip folks?

TIA

Had a bit of trouble with the ring gear bolt removal as they had some (Lol) "offset" to them.

But "I think" I'm good on the SG. All the internal gears look good. Splines look good. The cones look good as well and I see no signs of any bottoming. I can see the tooling marks in the bottom.......

What's your opinions on this sure grip folks?

TIA