Budget underhood AC retrofit.

My 74 Duster has Factory AC, but when I bought the car in pieces, there were no underhood parts included. I decided to install what I believe to be better, more readily available parts underhood as an upgrade to the system.

I used a compressor, brackets and the suction and discharge hoses sourced from a donor 1985 Dodge Truck. This may or may not be the best compressor choice, but I have always had great service from the C171 compressors and I knew I could source the compressor and brackets to fit my engine for free. I chose not to use the #6 hoses from the outlet of the condensor or the receiver/dryer from the donor truck since they had flat plate sealing flanges that I was not too keen on. I would have reused the hoses themselves but I could not easily source the appropriate fittings locally like I could with the bead lock hose. The donor truck used reduced bead lock hose for this line. My original plan was to use the condensor from the donor truck too but It was slightly too large and it also connected with the flat plate fittings. As well, the older pass through style condensers are not suited for modern refrigerants from what I understand.

So here is how it went so far, the compressor bolted on like it did on the truck. I should mention that not all aftermarket intakes will work with the factory AC brackets. I had to change my Edelbrock LD4B for an Edelbrock Performer 318/360 because of the offset thermostat housing on the performer. The Edelbrock Torker 2 also will work in a higher horsepower application. When I add my TBI in the future, I will likely go to a Torker 2 then.

It does require the crank pulley and water pump pulley from the donor truck as well. I also used the factory clutch fan from the donor truck which fit perfectly with the stock 26” rad (recored to 3 core) and factory shroud. It cools quite well. In order to run the 2 belts on the compressor, fan and alternator like it was originally, I will have to replace the alternator pulley with a 2 groove pulley. It is currently running with 1. The power steering side stays the same. There is an extra v-groove on the crank pulley for a second belt to the power steering pump but I could find no reason for it so I never added a second belt.

The suction hose is #12 bead lock hose. I used the factory fitting at the compressor and just cut the other fitting off and crimped on a #12 Female O-ring to #12 bead lock straight hose fitting for it to attach to the outlet of the factory Duster evaporator. There is plenty of hose for this. The discharge hose is #8 bead lock hose. I used the factory fitting at the compressor and will just cut the other fitting off and crimp on a #8 female O-ring to #8 bead lock straight or 45 degree hose fitting to connect to my aftermarket condenser. There is barely enough hose on this one (but there is enough) and I may have to modify the Rad support to allow for the fitting to connect to the condenser. I could adjust the mounting of the condenser to avoid this but I feel that the slight cut to the rad support is the best solution. The final decision will be made when I do the hook ups. Remember, if you choose the 45 degree fitting, it must be clocked correctly so no twist is introduced into the hose.

I mounted the receiver/dryer in the area formerly home to the charcoal canister. I will use a #6 female o-ring to #6 bead lock hose 90 deg. fitting at the outlet of the condenser and the same #6 female o-ring to #6 bead lock hose 90 deg. fitting at the inlet of the receiver/dryer. New #6 bead lock hose will be used in this section. At the outlet of the receiver/dryer another #6 female o-ring to #6 bead lock hose 90 deg. fitting will be used on another piece of new hose. On the other end of the new hose a #6 female o-ring to #6 bead lock hose 45 deg. Fitting will connect to the expansion valve.

The expansion valve connects directly to the #8 Female O-ring inlet on the factory evaporator. Remember the fittings must be clocked correctly so no twist is introduced into the hose.

The receiver/dryer I chose has a port for a pressure switch that controls both low pressure cut out and high pressure cycling of the compressor. I ran the factory AC clutch wire from the Duster Harness to the pressure switch then to the clutch. The factory Dodge truck service ports will be retained with adapters for modern refrigerant screwed on to them.

When I an done, I will add pictures of compressor mounting, hose and wiring routing, condenser mounting and anything else I can think of that may help someone else learn from my mistakes. I have no prior AC experience and I am learning this all as I do this job. Some things could be done better I’m sure but this is how I chose to do it given the information I could find. I ordered a few wrong parts along the way but that’s part of the learning process. I hope others can benefit from my experiences!

If anyone wants to share experience or help me do this better, please do. The one part I am still not 100% sure on is the connections to the compressor. I did find some C171 inlet and outlet adapter fittings but they appear to be no longer available at any of the suppliers I contacted that showed them in their catalogs. I know lots are going to say I should have used a Sanden compressor, but I am trying this in an effort to keep costs down.

Cley

Parts list

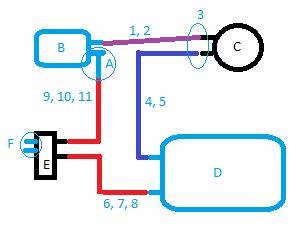

A) Expansion Valve with #6 Male insert O-ring inlet and #8 Male insert o-ring outlet(NAPA Part# A17191)

B) Stock Evaporator

C) C171 compressor from 1985 Dodge truck

D) Condensor with #8 Male insert O-ring inlet and #6 male insert o-ring outlet (Climaparts Part# CFNP1426)

E) Reciever/dryer with #6 Male insert O-ring inlet and outlet (NAPA Part# NTC A7959)

F) Pressure cycling switch (NAPA Part# A8381)

1. Suction hose from 1985 Dodge truck

2. #12 female O-ring to #12 bead lock hose crimp fitting (Part# BL 1304)

3. Compressor fitting seal kit (NAPA Part# NTC A 12561)

4. Discharge hose from 1985 Dodge truck

5. #8 female O-ring to #8 bead lock hose crimp fitting (Fitting Part# BL 1302(straight) BL 1312(45 deg))

6. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

7. #6 bead lock hose

8. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

9. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

10. #6 bead lock hose

11. #6 female O-ring to #6 bead lock hose 45 deg. crimp fitting (Part# BL 1311)

12. Mounting brackets and all related fasteners from 1985 Dodge truck

13. Crank pulley from 1985 Dodge truck

14. Water pump pulley from 1985 Dodge truck

15. Clutch fan from 1985 Dodge truck.

16. 2 groove alternator pulley (Part# not yet found)

17. Alternator belts for 1985 Dodge truck with air conditioning (NAPA Part# 25-7570 – 13-32x57 5/8)

• All NAPA part #s are from NAPA Canada website and do differ from U.S. NAPA site. When I gave US part numbers to my Canadian Napa guy, he had to cross reference them but it seemed to be no problem.

• All fitting part #s are from APCOAir catalog downloaded online. I sourced these fittings from NAPA as well, but they are available on E-bay and I realize that without my discount through work, NAPA isn’t always the place to buy from. I get my parts for about ½ of list.

• Climaparts condenser ordered on E-bay because it was 1/3rd the cost of picking it up locally and it appears to be the same unit that Bouchillon Performance includes in their underhood kits.

My 74 Duster has Factory AC, but when I bought the car in pieces, there were no underhood parts included. I decided to install what I believe to be better, more readily available parts underhood as an upgrade to the system.

I used a compressor, brackets and the suction and discharge hoses sourced from a donor 1985 Dodge Truck. This may or may not be the best compressor choice, but I have always had great service from the C171 compressors and I knew I could source the compressor and brackets to fit my engine for free. I chose not to use the #6 hoses from the outlet of the condensor or the receiver/dryer from the donor truck since they had flat plate sealing flanges that I was not too keen on. I would have reused the hoses themselves but I could not easily source the appropriate fittings locally like I could with the bead lock hose. The donor truck used reduced bead lock hose for this line. My original plan was to use the condensor from the donor truck too but It was slightly too large and it also connected with the flat plate fittings. As well, the older pass through style condensers are not suited for modern refrigerants from what I understand.

So here is how it went so far, the compressor bolted on like it did on the truck. I should mention that not all aftermarket intakes will work with the factory AC brackets. I had to change my Edelbrock LD4B for an Edelbrock Performer 318/360 because of the offset thermostat housing on the performer. The Edelbrock Torker 2 also will work in a higher horsepower application. When I add my TBI in the future, I will likely go to a Torker 2 then.

It does require the crank pulley and water pump pulley from the donor truck as well. I also used the factory clutch fan from the donor truck which fit perfectly with the stock 26” rad (recored to 3 core) and factory shroud. It cools quite well. In order to run the 2 belts on the compressor, fan and alternator like it was originally, I will have to replace the alternator pulley with a 2 groove pulley. It is currently running with 1. The power steering side stays the same. There is an extra v-groove on the crank pulley for a second belt to the power steering pump but I could find no reason for it so I never added a second belt.

The suction hose is #12 bead lock hose. I used the factory fitting at the compressor and just cut the other fitting off and crimped on a #12 Female O-ring to #12 bead lock straight hose fitting for it to attach to the outlet of the factory Duster evaporator. There is plenty of hose for this. The discharge hose is #8 bead lock hose. I used the factory fitting at the compressor and will just cut the other fitting off and crimp on a #8 female O-ring to #8 bead lock straight or 45 degree hose fitting to connect to my aftermarket condenser. There is barely enough hose on this one (but there is enough) and I may have to modify the Rad support to allow for the fitting to connect to the condenser. I could adjust the mounting of the condenser to avoid this but I feel that the slight cut to the rad support is the best solution. The final decision will be made when I do the hook ups. Remember, if you choose the 45 degree fitting, it must be clocked correctly so no twist is introduced into the hose.

I mounted the receiver/dryer in the area formerly home to the charcoal canister. I will use a #6 female o-ring to #6 bead lock hose 90 deg. fitting at the outlet of the condenser and the same #6 female o-ring to #6 bead lock hose 90 deg. fitting at the inlet of the receiver/dryer. New #6 bead lock hose will be used in this section. At the outlet of the receiver/dryer another #6 female o-ring to #6 bead lock hose 90 deg. fitting will be used on another piece of new hose. On the other end of the new hose a #6 female o-ring to #6 bead lock hose 45 deg. Fitting will connect to the expansion valve.

The expansion valve connects directly to the #8 Female O-ring inlet on the factory evaporator. Remember the fittings must be clocked correctly so no twist is introduced into the hose.

The receiver/dryer I chose has a port for a pressure switch that controls both low pressure cut out and high pressure cycling of the compressor. I ran the factory AC clutch wire from the Duster Harness to the pressure switch then to the clutch. The factory Dodge truck service ports will be retained with adapters for modern refrigerant screwed on to them.

When I an done, I will add pictures of compressor mounting, hose and wiring routing, condenser mounting and anything else I can think of that may help someone else learn from my mistakes. I have no prior AC experience and I am learning this all as I do this job. Some things could be done better I’m sure but this is how I chose to do it given the information I could find. I ordered a few wrong parts along the way but that’s part of the learning process. I hope others can benefit from my experiences!

If anyone wants to share experience or help me do this better, please do. The one part I am still not 100% sure on is the connections to the compressor. I did find some C171 inlet and outlet adapter fittings but they appear to be no longer available at any of the suppliers I contacted that showed them in their catalogs. I know lots are going to say I should have used a Sanden compressor, but I am trying this in an effort to keep costs down.

Cley

Parts list

A) Expansion Valve with #6 Male insert O-ring inlet and #8 Male insert o-ring outlet(NAPA Part# A17191)

B) Stock Evaporator

C) C171 compressor from 1985 Dodge truck

D) Condensor with #8 Male insert O-ring inlet and #6 male insert o-ring outlet (Climaparts Part# CFNP1426)

E) Reciever/dryer with #6 Male insert O-ring inlet and outlet (NAPA Part# NTC A7959)

F) Pressure cycling switch (NAPA Part# A8381)

1. Suction hose from 1985 Dodge truck

2. #12 female O-ring to #12 bead lock hose crimp fitting (Part# BL 1304)

3. Compressor fitting seal kit (NAPA Part# NTC A 12561)

4. Discharge hose from 1985 Dodge truck

5. #8 female O-ring to #8 bead lock hose crimp fitting (Fitting Part# BL 1302(straight) BL 1312(45 deg))

6. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

7. #6 bead lock hose

8. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

9. #6 female O-ring to #6 bead lock hose 90 deg. crimp fitting (Part# BL 1321)

10. #6 bead lock hose

11. #6 female O-ring to #6 bead lock hose 45 deg. crimp fitting (Part# BL 1311)

12. Mounting brackets and all related fasteners from 1985 Dodge truck

13. Crank pulley from 1985 Dodge truck

14. Water pump pulley from 1985 Dodge truck

15. Clutch fan from 1985 Dodge truck.

16. 2 groove alternator pulley (Part# not yet found)

17. Alternator belts for 1985 Dodge truck with air conditioning (NAPA Part# 25-7570 – 13-32x57 5/8)

• All NAPA part #s are from NAPA Canada website and do differ from U.S. NAPA site. When I gave US part numbers to my Canadian Napa guy, he had to cross reference them but it seemed to be no problem.

• All fitting part #s are from APCOAir catalog downloaded online. I sourced these fittings from NAPA as well, but they are available on E-bay and I realize that without my discount through work, NAPA isn’t always the place to buy from. I get my parts for about ½ of list.

• Climaparts condenser ordered on E-bay because it was 1/3rd the cost of picking it up locally and it appears to be the same unit that Bouchillon Performance includes in their underhood kits.