lifter galley crossover tube

Hello YellowRose. I have a question for you. If we agree that the Chevy crank and the Mopar crank are drilled the same and that the difference in timing is the location of the oil hole in the block,and assuming the difference in timing is 15-18 degrees as you said earlier, could the timing not be corrected right in the bearing saddle in the block.

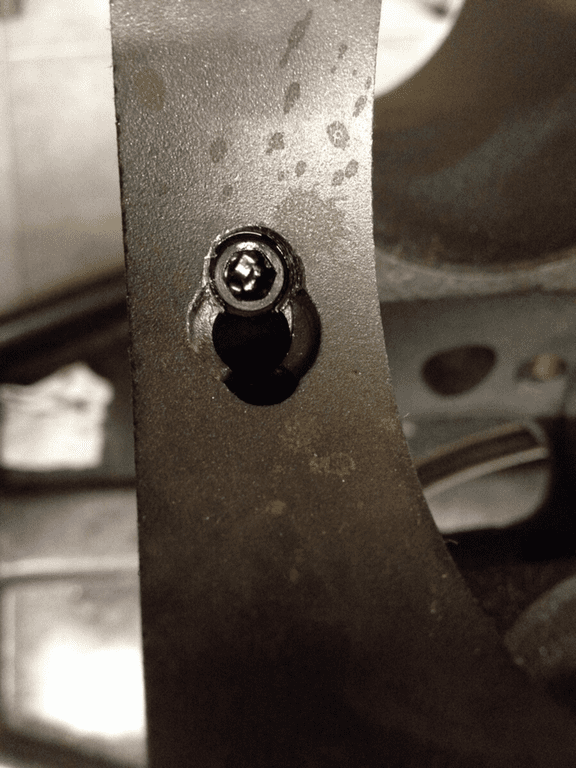

Reason I ask this is I have attached a picture of my "X" block number 1 main bearing saddle with the passage to the driver side blocked off.

Notice in the centre of the saddle there is a counter bore. I see many Chrysler small blocks on this forum that have this counterbore.

My 1969 340 block(not the x block) does not have this counterbore.

One of the modifications that is demonstrated on Guitar Jones oil thread and the Sanborn thread on Mopar chat, is to slot the oil holes in the upper bearing halves to 1/2 inch long.

If this mod were done to the bearings and installed in a block with this counterbore, would this not move the oil timing to the center of the bearing saddle and correct the oil timing?

Although the oil is still coming to the bearing saddle at the 11:00 position, would it not transfer under the bearing shell to the centre of the bearing before exiting to the crankshaft.

At the very least it would have full flow at the 12:00 position just like a Chevy.

I recall many years ago that Mopar performance used to sell bearings with this slot already in them.

Hello YellowRose. I have a question for you. If we agree that the Chevy crank and the Mopar crank are drilled the same and that the difference in timing is the location of the oil hole in the block,and assuming the difference in timing is 15-18 degrees as you said earlier, could the timing not be corrected right in the bearing saddle in the block.

Reason I ask this is I have attached a picture of my "X" block number 1 main bearing saddle with the passage to the driver side blocked off.

Notice in the centre of the saddle there is a counter bore. I see many Chrysler small blocks on this forum that have this counterbore.

My 1969 340 block(not the x block) does not have this counterbore.

One of the modifications that is demonstrated on Guitar Jones oil thread and the Sanborn thread on Mopar chat, is to slot the oil holes in the upper bearing halves to 1/2 inch long.

If this mod were done to the bearings and installed in a block with this counterbore, would this not move the oil timing to the center of the bearing saddle and correct the oil timing?

Although the oil is still coming to the bearing saddle at the 11:00 position, would it not transfer under the bearing shell to the centre of the bearing before exiting to the crankshaft.

At the very least it would have full flow at the 12:00 position just like a Chevy.

I recall many years ago that Mopar performance used to sell bearings with this slot already in them.