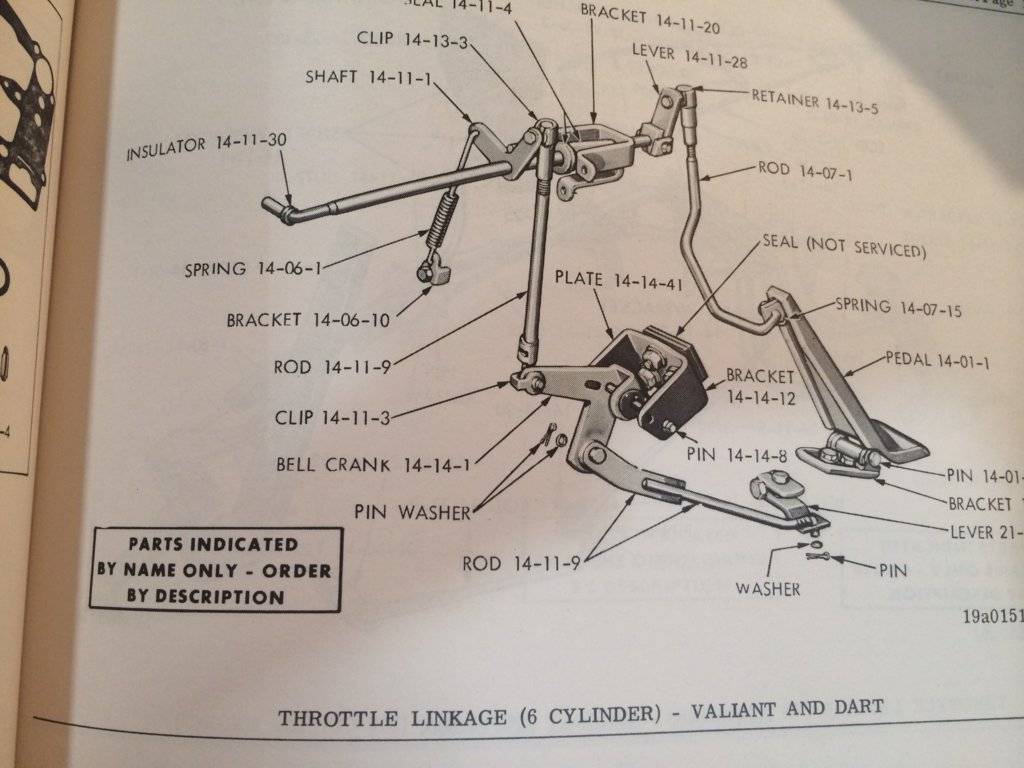

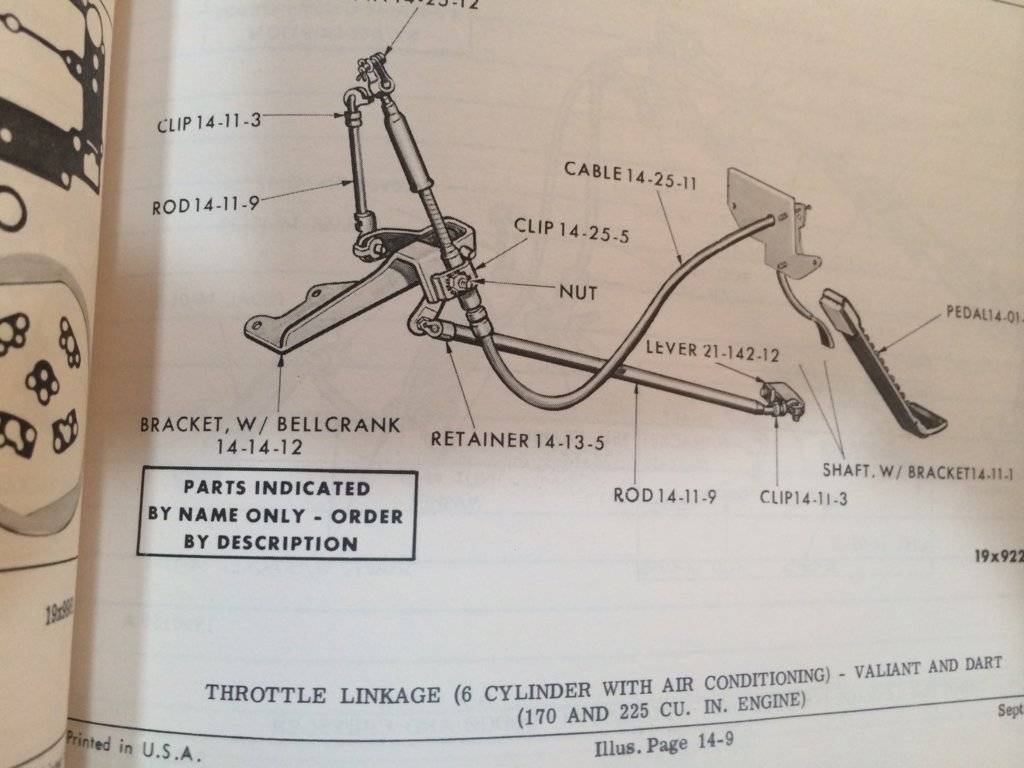

Slapping a factory a/c (knee knocker) on a 66 Valiant. Got it bolted up no issues. But the owner said something about needing to use a throttle cable and not the linkage. So I break out the handy dandy 66 service manual, and it's showing two types of linkages.

#1: why? Is there an issue with using the throttle linkage?

Car is a 66 Valiant, originally non a/c and auto trans. What will I need to make this happen? Got the condenser, all the lines, pump, brackets and idler pulley.

#1: why? Is there an issue with using the throttle linkage?

Car is a 66 Valiant, originally non a/c and auto trans. What will I need to make this happen? Got the condenser, all the lines, pump, brackets and idler pulley.