Proforged sleeved polygraphite LCA bushings!

James-

I'm sorry, but that's just not true about the OE rubber bushings. Take a set apart if you don't believe me. It's just a friction fit, there's no permanent bonding. At least not on any of the one's being sold today. It's true, the OE rubber bushings don't spin in/on the shells/sleeves and the motion is just the flex in the material. But it's just a friction fit that holds the bushing in place.

Brand new set of Moog LCA bushings, as they came in my QA1 LCA's. Please note the edge imperfections on the bushing already

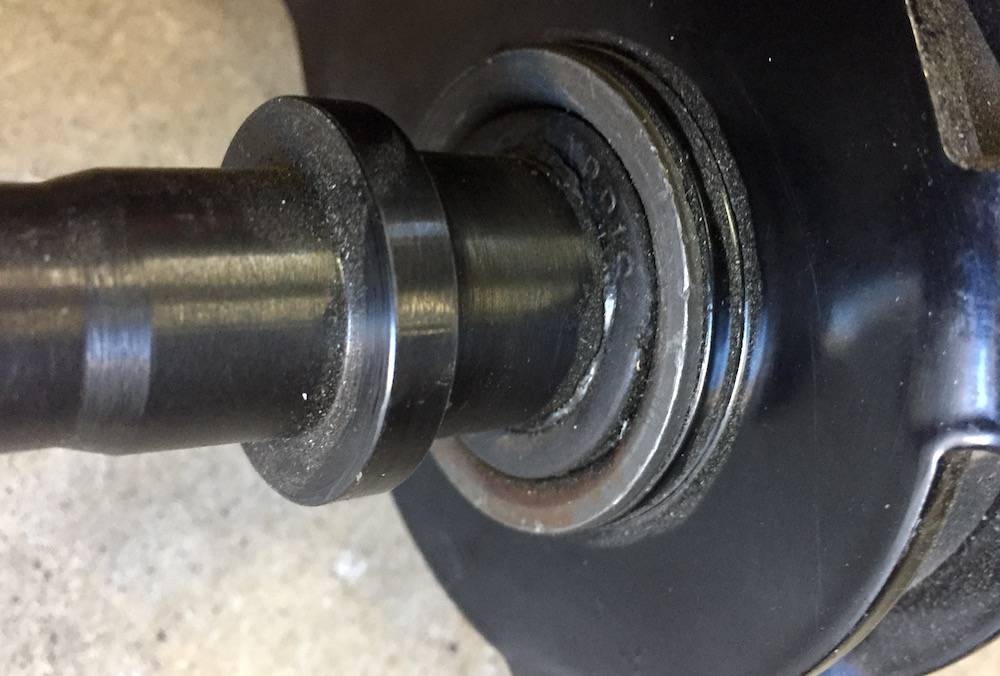

Pin pressed out

Inner sleeve pressed out, bushing peeled out of the outer sleeve using a screwdriver, by hand. No bonding to hold it in, just the friction of the bushing in the shell. Notice how clean and smooth the shell is inside, the couple of scratches in the shell are from the tip of the screwdriver I used to peel the bushing out.

The bushing itself. The rough edges were present before the deconstruction started. Notice the shape of the bushing! This is to create additional pressure on the sleeves to hold them in place, it's a friction fit. All of the material on the outside of the upper shoulder is pressed into the shell so it's even with that shoulder. It's hard to see in this picture but with the bushing out of the shells the inner part of the bushing is concave to allow for all that extra material to press in against the inner shell. The part of the bushing that was against the outer shell is nice and smooth, no tear outs from being bonded into the shell. And again, I removed the bushing by hand, so, definitely not "permanently" bonded.

James-

I'm sorry, but that's just not true about the OE rubber bushings. Take a set apart if you don't believe me. It's just a friction fit, there's no permanent bonding. At least not on any of the one's being sold today. It's true, the OE rubber bushings don't spin in/on the shells/sleeves and the motion is just the flex in the material. But it's just a friction fit that holds the bushing in place.

Brand new set of Moog LCA bushings, as they came in my QA1 LCA's. Please note the edge imperfections on the bushing already

Pin pressed out

Inner sleeve pressed out, bushing peeled out of the outer sleeve using a screwdriver, by hand. No bonding to hold it in, just the friction of the bushing in the shell. Notice how clean and smooth the shell is inside, the couple of scratches in the shell are from the tip of the screwdriver I used to peel the bushing out.

The bushing itself. The rough edges were present before the deconstruction started. Notice the shape of the bushing! This is to create additional pressure on the sleeves to hold them in place, it's a friction fit. All of the material on the outside of the upper shoulder is pressed into the shell so it's even with that shoulder. It's hard to see in this picture but with the bushing out of the shells the inner part of the bushing is concave to allow for all that extra material to press in against the inner shell. The part of the bushing that was against the outer shell is nice and smooth, no tear outs from being bonded into the shell. And again, I removed the bushing by hand, so, definitely not "permanently" bonded.