Budget underhood AC retrofit.

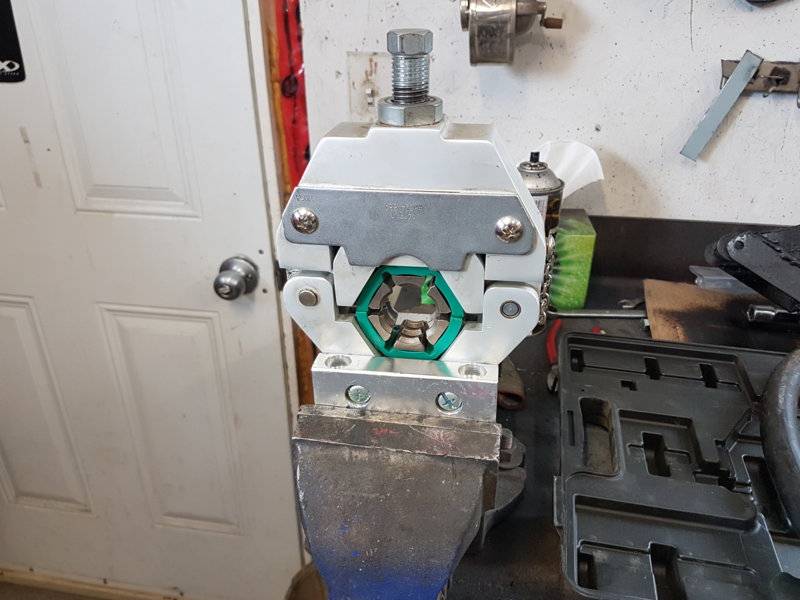

I finally got a chance to borrow my buddy’s AC hose crimper this weekend. I got all my hoses made and only ran into one snag. The expansion valve I found turned out to be incorrect. It has the correct #8 end to attach to the evaporator, but the #6 end that would attach to the drier outlet hose is not correct. The pipe and o-ring part appears to be right but the nut does not fit the threads. So, back to the drawing board searching for parts on that one.

The original #12 hose from the truck works very well with the new end crimped on. I could have definitely shortened it a little but it is fine how it is in my opinion. Not show car quality, but that is not what I was going for.

I was worried about the #8 hose on the outlet of the compressor being too short, but it turned out that I had to cut an additional 1 ½” off of it to make it work with the new compression fitting. I’m pretty mad at myself about the hole I hacked into the rad support to allow room for the fitting (see pictures), as it could have been way smaller and neater, so I guess I’ll have to figure a way to clean it up a bit. Again, not a show car but not a hack job either.

The #6 line from the bottom of the condensor to the drier worked out really well. If I had it to do again, I would look at putting the drier on the front side of the rad support, just to declutter the engine bay a little. It will work like it is though.

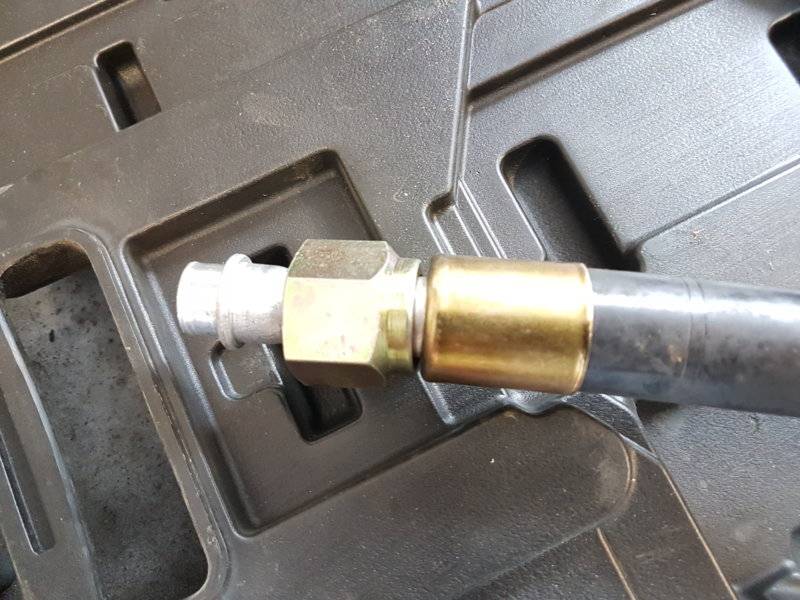

Now here’s the last piece to the puzzle. The damn expansion valve. Once I find a suitable valve, I’ll update the parts list on the first post of this to include the correct part number.

So what did I learn so far?

Cley

I finally got a chance to borrow my buddy’s AC hose crimper this weekend. I got all my hoses made and only ran into one snag. The expansion valve I found turned out to be incorrect. It has the correct #8 end to attach to the evaporator, but the #6 end that would attach to the drier outlet hose is not correct. The pipe and o-ring part appears to be right but the nut does not fit the threads. So, back to the drawing board searching for parts on that one.

The original #12 hose from the truck works very well with the new end crimped on. I could have definitely shortened it a little but it is fine how it is in my opinion. Not show car quality, but that is not what I was going for.

I was worried about the #8 hose on the outlet of the compressor being too short, but it turned out that I had to cut an additional 1 ½” off of it to make it work with the new compression fitting. I’m pretty mad at myself about the hole I hacked into the rad support to allow room for the fitting (see pictures), as it could have been way smaller and neater, so I guess I’ll have to figure a way to clean it up a bit. Again, not a show car but not a hack job either.

The #6 line from the bottom of the condensor to the drier worked out really well. If I had it to do again, I would look at putting the drier on the front side of the rad support, just to declutter the engine bay a little. It will work like it is though.

Now here’s the last piece to the puzzle. The damn expansion valve. Once I find a suitable valve, I’ll update the parts list on the first post of this to include the correct part number.

So what did I learn so far?

- The Mastercool crimper I borrowed is a nice, easy to use tool that should make good long lasting crimps. My buddy has been using it for a few years now.

- The hoses could be routed for a much cleaner install, but that would add additional cost since I never had to purchase any #12 or #8 hose the way I did it.

- The #6 hose is difficult to purchase in short pieces, at least around here, so I would possibly look at using hard line like the factory did next time.

- With a lot of the research done, this is a relatively easy retrofit using easy to find junk yard parts and brackets. I maybe would not have to, but I think I’ll put on a reman compressor before charging the system up.

Cley