Subframe connectors......

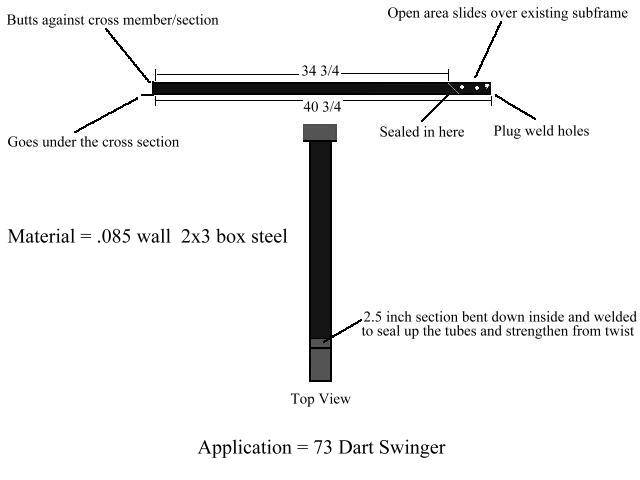

On my 73 I went just inside that and lined up directly behind the rail section that goes forward on the front side of the cross member.

I also used 2x3 laying flat and pushed it up against the floor but didn't mod the floor at all.

They do taper slightly together as they go forward, but it made sense to me to tie in directly behind the frame sections that run forward from there.

I also used a piece of angle on the ends of the rails and welded it all the way under the cross member into the end of the section that runs forward from there.

I'm not saying I think you should do exactly the same, but just showing the flat area you could use to solve your problem.

It kind of looks like one big nasty weld, but it's actually two side by side.

It was the first thing I did after I got the car so forgive the crappy looking single exhaust in the pic.:D

On my 73 I went just inside that and lined up directly behind the rail section that goes forward on the front side of the cross member.

I also used 2x3 laying flat and pushed it up against the floor but didn't mod the floor at all.

They do taper slightly together as they go forward, but it made sense to me to tie in directly behind the frame sections that run forward from there.

I also used a piece of angle on the ends of the rails and welded it all the way under the cross member into the end of the section that runs forward from there.

I'm not saying I think you should do exactly the same, but just showing the flat area you could use to solve your problem.

It kind of looks like one big nasty weld, but it's actually two side by side.

It was the first thing I did after I got the car so forgive the crappy looking single exhaust in the pic.:D