milling heads for comp ratio increase

Thank you heaps for working out the static CR. :) I was actually going to get an accurate CC on each one first before I put the numbers in myself. But that has given me a good idea - but pretty low isn't it! :eek: . I have looked at youtube and there are plenty of videos showing how to do the measurements for cc.

But that is good news about the 30thou milling amount - it seems a lot compared to what is recommended! I can easily do a dummy assemble of heads and intake and check how much room I have to play with and how the bolt holes line up. Maybe first with a 40thou Felpro and then with no gasket and look at how it changes etc. If I can take 30 thou off, that is a very good start. If it is tight and almost there, I don't see why I can't run a rat-tail file through the intake holes to facilitate lining up.

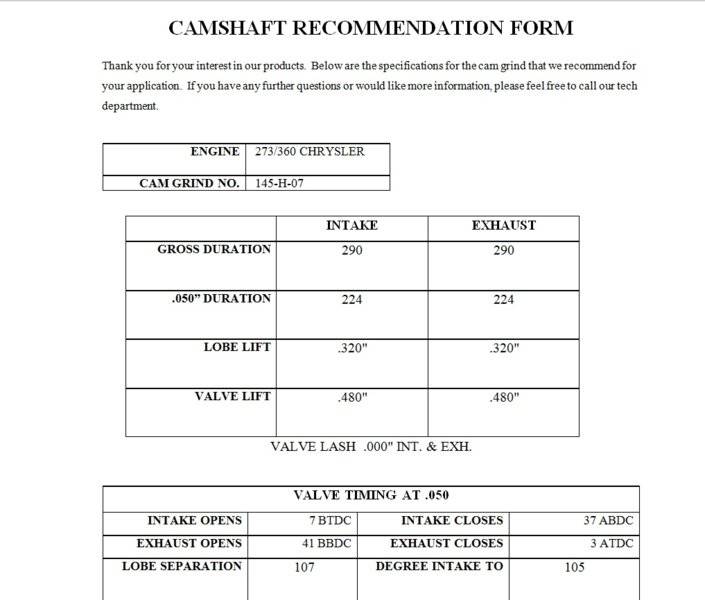

You may be right about the cam - here attached are the specs. It is an 'Ol Skool Schneider cam, valve lift 0.48, 290 duration and look at the lobe separation - only 107. So this cam may be a little rough idle and perhaps more suited to a hotter 340, but it's the only one I have and I don't see why it couldn't be made to work pretty well. Schneider didn't give me the RPM range but at a guess I would say 1800-6200, Does that sound close? (just a guess) I am running a 2500 stall so that will help -final drive is 3.23 and as I mentioned, it is a light-ish vehicle around 2750pounds

Thank you heaps for working out the static CR. :) I was actually going to get an accurate CC on each one first before I put the numbers in myself. But that has given me a good idea - but pretty low isn't it! :eek: . I have looked at youtube and there are plenty of videos showing how to do the measurements for cc.

But that is good news about the 30thou milling amount - it seems a lot compared to what is recommended! I can easily do a dummy assemble of heads and intake and check how much room I have to play with and how the bolt holes line up. Maybe first with a 40thou Felpro and then with no gasket and look at how it changes etc. If I can take 30 thou off, that is a very good start. If it is tight and almost there, I don't see why I can't run a rat-tail file through the intake holes to facilitate lining up.

You may be right about the cam - here attached are the specs. It is an 'Ol Skool Schneider cam, valve lift 0.48, 290 duration and look at the lobe separation - only 107. So this cam may be a little rough idle and perhaps more suited to a hotter 340, but it's the only one I have and I don't see why it couldn't be made to work pretty well. Schneider didn't give me the RPM range but at a guess I would say 1800-6200, Does that sound close? (just a guess) I am running a 2500 stall so that will help -final drive is 3.23 and as I mentioned, it is a light-ish vehicle around 2750pounds