Cuda_Al's Copper 1967 Barracuda Fastback

On to the engine, just a reminder, this is basically a stock rebuild and it is going back to a 2-bbl. A standard block was selected and was machined to 0.030 over.

Day 1

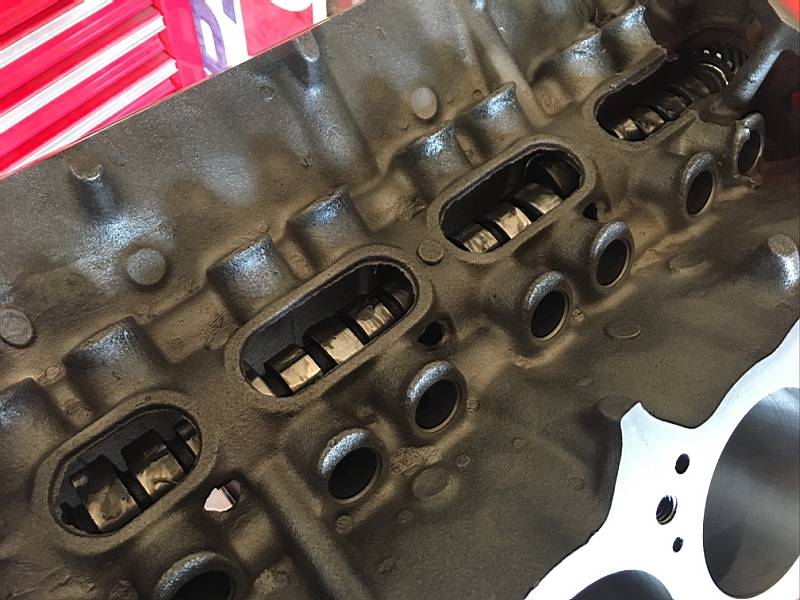

Once the machine work was done the first thing was to clean the inside of the water jacket, something that should have been done prior to sending it out. Bristle brushes and coat hangers were used in every conceivable angle in every opening in the block, some of the brushes were bent in a curve and worked around the back of the cylinders. This was done multiple time with the block rolled at different angles constantly rinsing with high pressure water. Once that was done the outside of the block was washed with soap and water, then blown off with air to dry.

With the block clean the heads, intake, valve covers, oil pan, oil adapter, and timing cover were put together. The other parts were cleaned and the assembly was painted. My engine guy prefers the block to be painted first to prevent the cast iron from soaking up oil, it will get painted again once it is together.

All the parts were removed and the inside was sprayed down with WD-40 and wiped down to clean any machining dust that may still be there. Once clean the inside was sprayed again to protect it.

Day 2

With the rough cleaning and prep done the detail cleaning could start. Some small (long) soft bristle brushes were run through all the different oil passages, cleaning the brush before pulling it back out.

With the block thoroughly clean the first thing was to check all the machining, the main bearings were fitted and the caps bolted and torqued down. Multiple measurements were taken and compared to the crank (this block was aligned bored). Each of the pistons were measured and compared to the bore to verify the piston to wall clearance.

With all the numbers checking out the distributor bushing was knocked in with an old distributor drive gear. Then the cam was installed (with assembly lube) to verify that the bearing were installed correctly (wouldn’t want to figure that out with the engine all together), along with the thrust plate (blue Loctite on the bolts, all 4 were used).

Day 3

Good to go the various oil plugs were installed, all with sealant.

From there the crank was inspected for flaws and the oil passages cleaned. Main bearing installed and the crank (with assembly lube) and caps, all torqued, check rotation. Next was to fit the timing chain and check the slack. The chain was looser than desired because the engine was align bored, something I didn't think about when I ordered the chain. My friend that is helping me with the assembly said to get the 0.010 under chain, well that one came in and he felt it was a little on the tight side so a new one was ordered (a 0.005 under).

0.010 under

0.005 under

Alan

On to the engine, just a reminder, this is basically a stock rebuild and it is going back to a 2-bbl. A standard block was selected and was machined to 0.030 over.

Day 1

Once the machine work was done the first thing was to clean the inside of the water jacket, something that should have been done prior to sending it out. Bristle brushes and coat hangers were used in every conceivable angle in every opening in the block, some of the brushes were bent in a curve and worked around the back of the cylinders. This was done multiple time with the block rolled at different angles constantly rinsing with high pressure water. Once that was done the outside of the block was washed with soap and water, then blown off with air to dry.

With the block clean the heads, intake, valve covers, oil pan, oil adapter, and timing cover were put together. The other parts were cleaned and the assembly was painted. My engine guy prefers the block to be painted first to prevent the cast iron from soaking up oil, it will get painted again once it is together.

All the parts were removed and the inside was sprayed down with WD-40 and wiped down to clean any machining dust that may still be there. Once clean the inside was sprayed again to protect it.

Day 2

With the rough cleaning and prep done the detail cleaning could start. Some small (long) soft bristle brushes were run through all the different oil passages, cleaning the brush before pulling it back out.

With the block thoroughly clean the first thing was to check all the machining, the main bearings were fitted and the caps bolted and torqued down. Multiple measurements were taken and compared to the crank (this block was aligned bored). Each of the pistons were measured and compared to the bore to verify the piston to wall clearance.

With all the numbers checking out the distributor bushing was knocked in with an old distributor drive gear. Then the cam was installed (with assembly lube) to verify that the bearing were installed correctly (wouldn’t want to figure that out with the engine all together), along with the thrust plate (blue Loctite on the bolts, all 4 were used).

Day 3

Good to go the various oil plugs were installed, all with sealant.

From there the crank was inspected for flaws and the oil passages cleaned. Main bearing installed and the crank (with assembly lube) and caps, all torqued, check rotation. Next was to fit the timing chain and check the slack. The chain was looser than desired because the engine was align bored, something I didn't think about when I ordered the chain. My friend that is helping me with the assembly said to get the 0.010 under chain, well that one came in and he felt it was a little on the tight side so a new one was ordered (a 0.005 under).

0.010 under

0.005 under

Alan