Clutch Fan

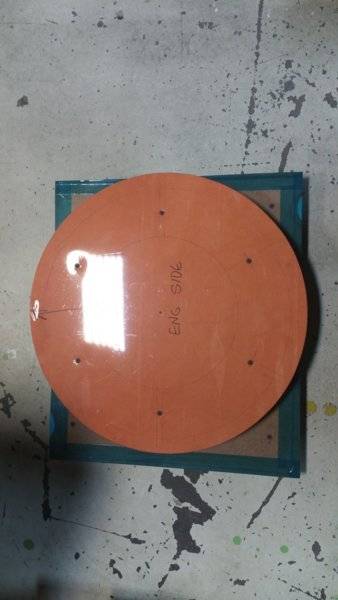

More pix. First is the risers made from old 2×4 blocks to get the proper height. The 1x1s on the back stiffen the mould, and give something to stretch and staple the cotton fabric to. The 3rd pic is of the mould release plastic and tapes. 4th pic, I used 4 coats of fiberglass resin on the cotton fabric, allowing time to dry between coats, and light scuffing between coats. This gave it a nice sandable gel coat and allowed it to get stiff enough to pull from the mould, then i screwed it down to a plywood board on sawhorses and fiberglassed the inside.

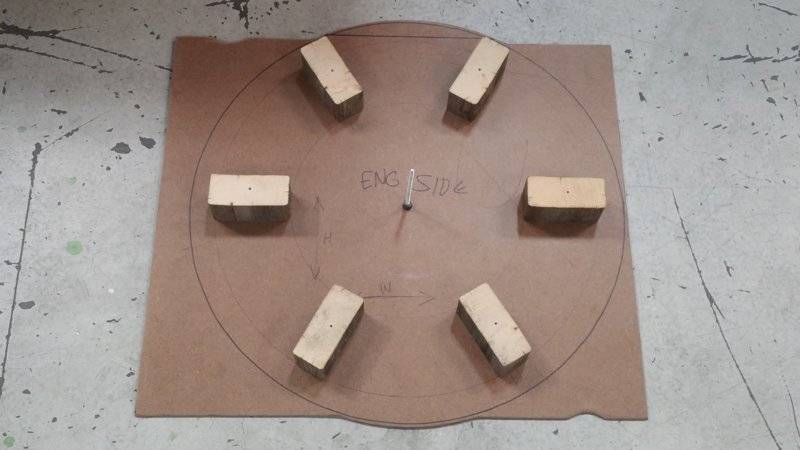

The wooden bucks dimensions, and circular disc diameter, offset, and height the most important things in doing this. The mould has to be perfect in dimension, since you are making the part from it. If the mould is off in any direction or height, your part will be too.

More pix. First is the risers made from old 2×4 blocks to get the proper height. The 1x1s on the back stiffen the mould, and give something to stretch and staple the cotton fabric to. The 3rd pic is of the mould release plastic and tapes. 4th pic, I used 4 coats of fiberglass resin on the cotton fabric, allowing time to dry between coats, and light scuffing between coats. This gave it a nice sandable gel coat and allowed it to get stiff enough to pull from the mould, then i screwed it down to a plywood board on sawhorses and fiberglassed the inside.

The wooden bucks dimensions, and circular disc diameter, offset, and height the most important things in doing this. The mould has to be perfect in dimension, since you are making the part from it. If the mould is off in any direction or height, your part will be too.