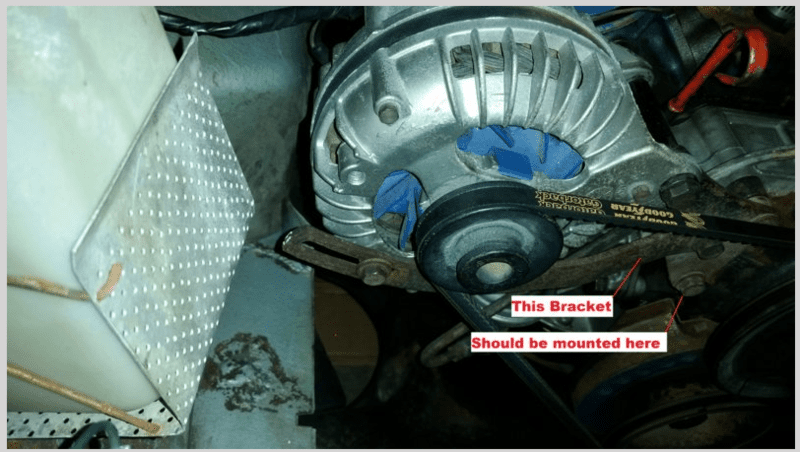

So I decided to relocate the alternator adjuster bracket to the correct bolt. Figured it would be as easy as remove one bolt, loosen the adjuster bolt on the alt. remove the correct water pump bolt, swap the bracket over, add some anti seize to the threads and reinstall the bolts.

NAAAAA.... looks like someone forgot to add anti seize to the lower bolt last time the water pump was changed in 1998. (by a shop before I owned the car)

Any thoughts on nondestructive removal?

I used a breaker bar and did it not budge it. I tried forward and backward. I am the king of breaking off bolts so I did not put a lot of force on it but enough that it should have come off.

The engine was cold, was thinking of trying hot. I don't really want to pull the entire front cover off if I don't have to at this point.

Speaking of front covers.... the 273 has passenger side timing marks on a metal bracket. The cover also has timing marks cast into it on the drivers side. Did all 273 timing covers come that way or is this a 70 something and up cover. I know it was replaced in 98.

NAAAAA.... looks like someone forgot to add anti seize to the lower bolt last time the water pump was changed in 1998. (by a shop before I owned the car)

Any thoughts on nondestructive removal?

I used a breaker bar and did it not budge it. I tried forward and backward. I am the king of breaking off bolts so I did not put a lot of force on it but enough that it should have come off.

The engine was cold, was thinking of trying hot. I don't really want to pull the entire front cover off if I don't have to at this point.

Speaking of front covers.... the 273 has passenger side timing marks on a metal bracket. The cover also has timing marks cast into it on the drivers side. Did all 273 timing covers come that way or is this a 70 something and up cover. I know it was replaced in 98.