rmchrgr

Skate And Destroy

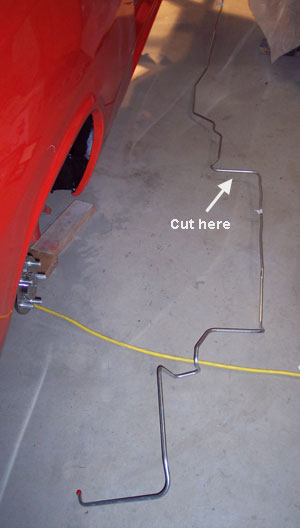

How do you all route your 3/8" fuel line with frame connectors?

Running a new front to back hard line and am running into difficulty with the frame connector, it's right where the line passes through the trans. cross member. I need to make some tricky bends and it's kicking my ***, went through a whole roll of line already trying different things, none of which were satisfactory. Was originally run through the cross memeber and made a hard left between the floor pan and top of the connector, then out to the pinch weld under the rocker.

Easiest would probably be to run it along the inside of the frame connector and attach with clips/self-tapping screws. My concern is that it ends up a few inches from the exhaust. Anyone do that?

Anyone run it under the connector?

Sorry, no pics at the moment. Thanks for any input.

- Greg

Running a new front to back hard line and am running into difficulty with the frame connector, it's right where the line passes through the trans. cross member. I need to make some tricky bends and it's kicking my ***, went through a whole roll of line already trying different things, none of which were satisfactory. Was originally run through the cross memeber and made a hard left between the floor pan and top of the connector, then out to the pinch weld under the rocker.

Easiest would probably be to run it along the inside of the frame connector and attach with clips/self-tapping screws. My concern is that it ends up a few inches from the exhaust. Anyone do that?

Anyone run it under the connector?

Sorry, no pics at the moment. Thanks for any input.

- Greg