who is running MRL (BAM) Lifters without lifter bore sleeves

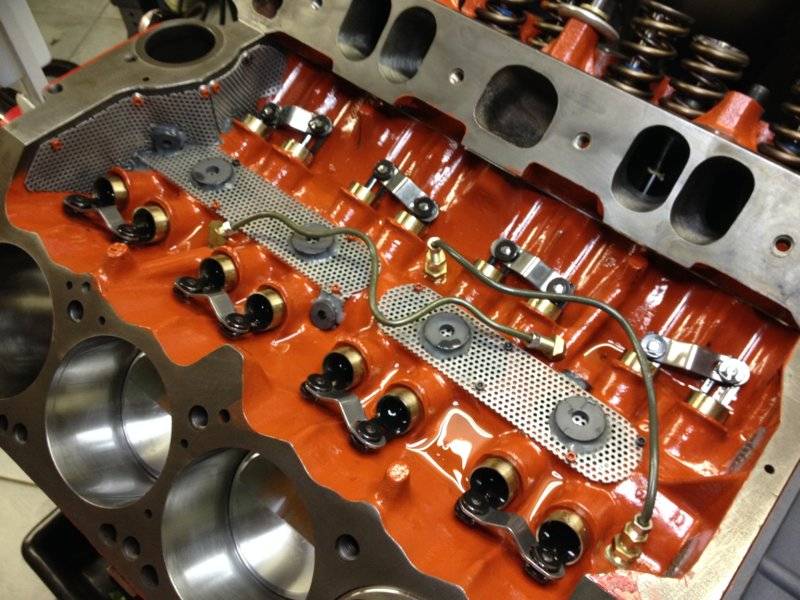

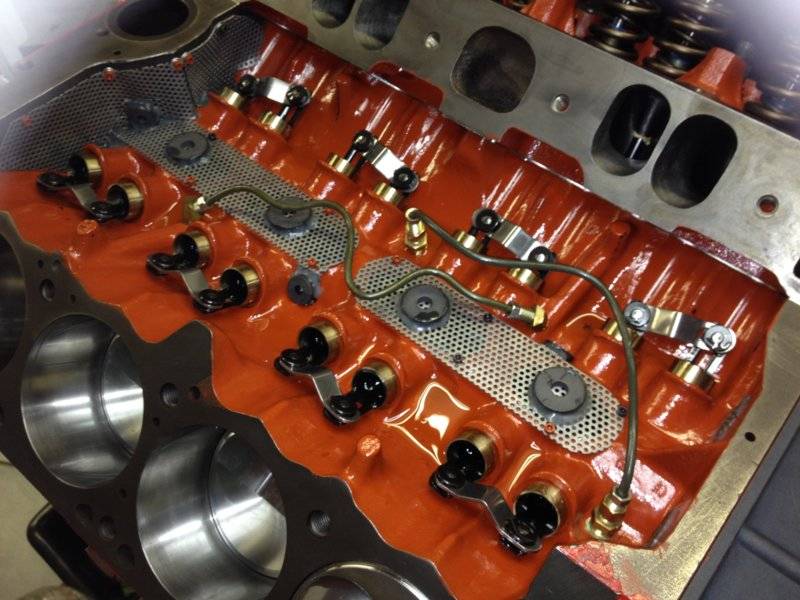

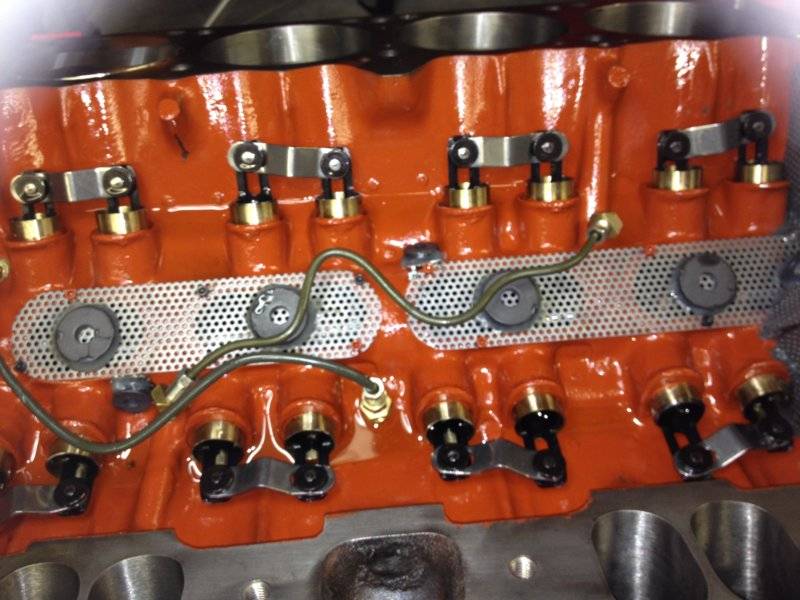

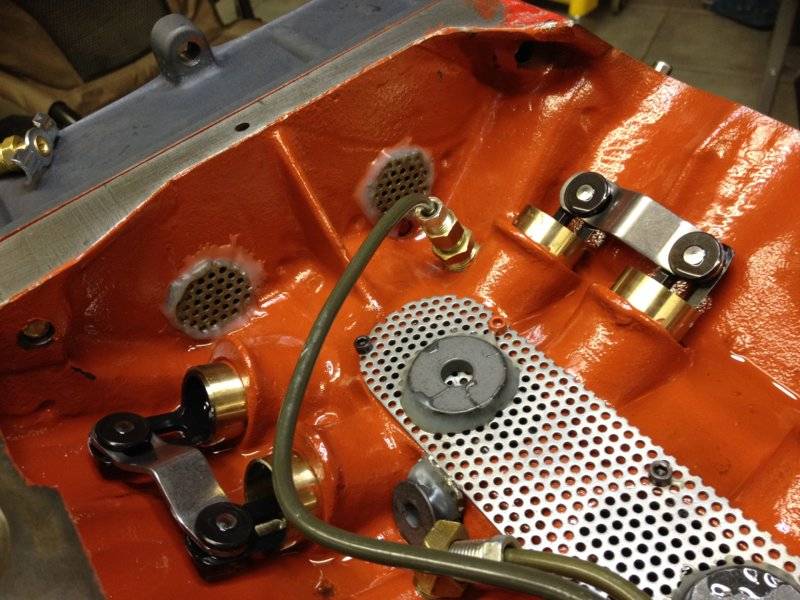

Just to add to this discussion, my current build I wanted to use the new bushed roller lifters from comp cams. These lifters have no needle bearings in the axle wheel and have an edm oil pressure feed hole directly to the bushing and axle assembly. As Pittsburgh racer has said I would never build a roller cam motor without a minimum of tubing the oil galley. Problem for me with these new lifters is they require some oil. With this build I decided to have the lifter bores bushed instead of tubing the block. The lifter bushings have a .030

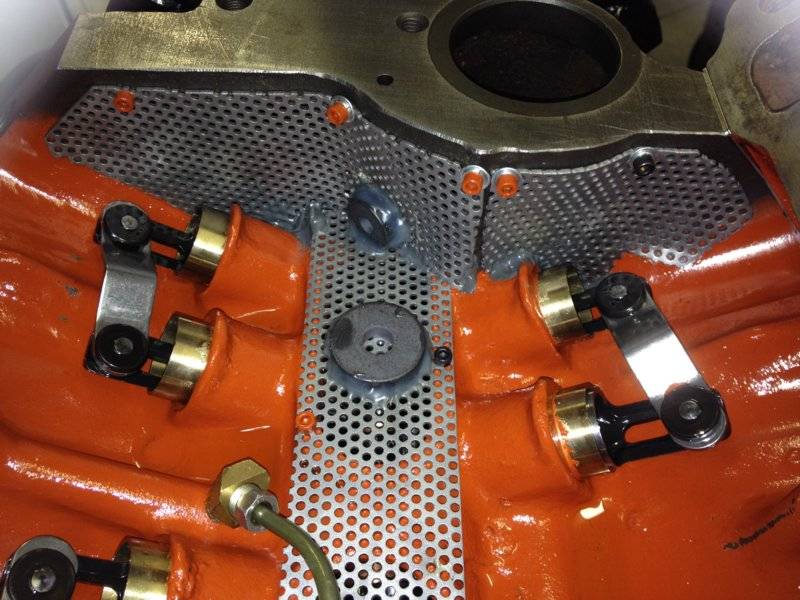

Feed hole to restrict oil leakage to the lifters. The block will use a high volume pump. I have also eliminated the rocker oiling through the cam bearings and will direct feed right from the main oil galley

With a brake line jumper tube mod from the stroker small block build book. Also one brake line feed over to the driver side lifter galley

To feed the other bank of lifters.

Also these new comp cams sportsman lifters have the link bar located inboard, so no goring of the block and the lifter axles are staked so they have no snap ring clips to fail either.

I am hoping for the best compromise of reliability if the valvetrain

And good oil pressure for the bottom end, and no needle bearing in the oil pump and pan if you loose a lifter.

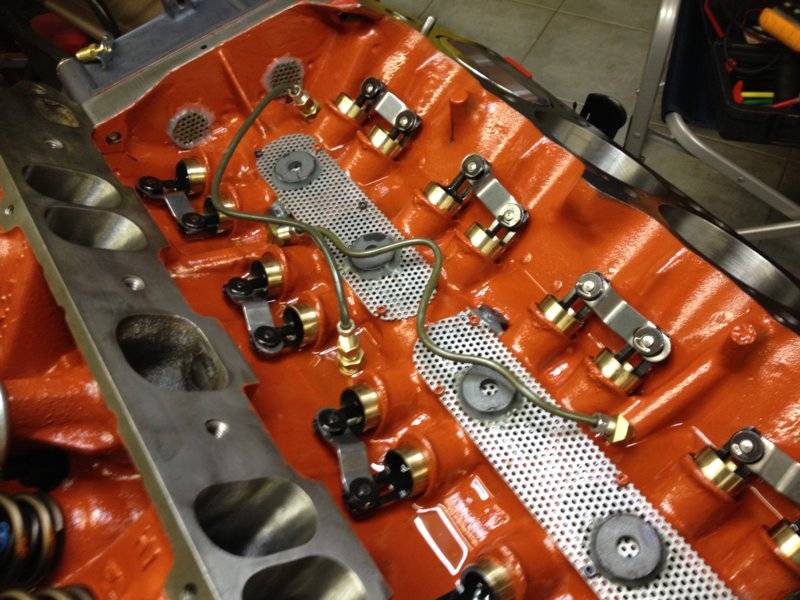

Just to add to this discussion, my current build I wanted to use the new bushed roller lifters from comp cams. These lifters have no needle bearings in the axle wheel and have an edm oil pressure feed hole directly to the bushing and axle assembly. As Pittsburgh racer has said I would never build a roller cam motor without a minimum of tubing the oil galley. Problem for me with these new lifters is they require some oil. With this build I decided to have the lifter bores bushed instead of tubing the block. The lifter bushings have a .030

Feed hole to restrict oil leakage to the lifters. The block will use a high volume pump. I have also eliminated the rocker oiling through the cam bearings and will direct feed right from the main oil galley

With a brake line jumper tube mod from the stroker small block build book. Also one brake line feed over to the driver side lifter galley

To feed the other bank of lifters.

Also these new comp cams sportsman lifters have the link bar located inboard, so no goring of the block and the lifter axles are staked so they have no snap ring clips to fail either.

I am hoping for the best compromise of reliability if the valvetrain

And good oil pressure for the bottom end, and no needle bearing in the oil pump and pan if you loose a lifter.