Old hat...

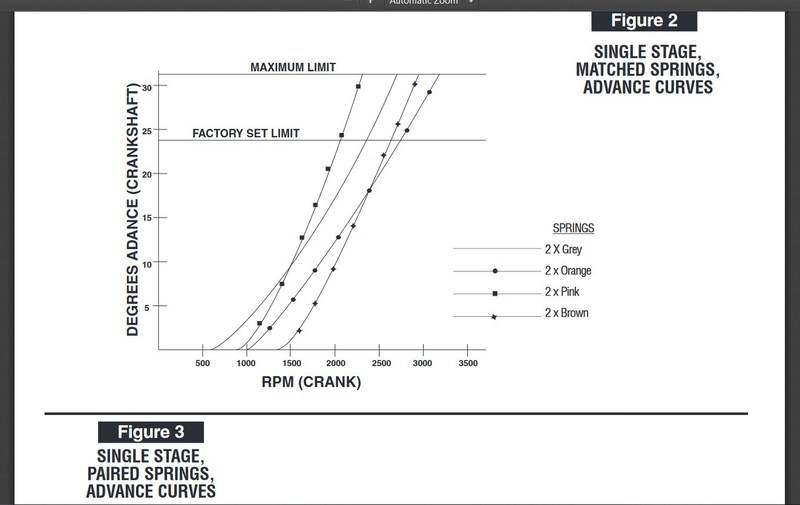

These curves are all to fast for what I am trying to do. even the Orange is in by 3000, and if it is limited to 24* then you can't run more than 10 initial for 24+10=34 total power timing. And 10 is gonna make it impossible to get the Transfer port synced.

I have aluminum heads and run 185psi with the HE3037Al cam (230/237/110/@.050) on 87E10 At 10.9Scr Heavily loaded with 3.55s.But I have a dash-mounted,dial-back timing box with a range of +7/- 8degrees. By only running 14* initial,and dialing 8* out I can drive 4mph@550rpm with that combo.

With 4.56s you might be able to drive as slow as 4mph@600rpm, but there is no way yur gonna do that with 20* idle timing because she is gonna buck and jump and fart until you ride the clutch. Even at 14* she is not likely to idle down to 600 without drama. And so that is why I recommend 14* as a starting point. You are only gonna go thru that low-rpm/low-timing once every time you leave from a stop. The rest of the time you are gonna be above 2000rpm/13mph, maybe above 2500/16mph; so don't let a measly 14* scare you, cuz you make it up with rate. But first you have to limit the power-timing to what the engine can handle.And then you add Vcan later, as much as she'll take,to smooth her out. (I run 24*)

I called it D-O-N-E.

These curves are all to fast for what I am trying to do. even the Orange is in by 3000, and if it is limited to 24* then you can't run more than 10 initial for 24+10=34 total power timing. And 10 is gonna make it impossible to get the Transfer port synced.

This statement tells me I am exactly on the right track,so you gotta slow the curve down and limit it down.Limit that D to 20degrees or less, and slow it down to all in by 3400.Then set the initial to 34 less whatever you managed to get in the D, and I'm targeting 14*.

Because you say your vacuum is so low, even with the initial timing cranked up, I'm trying to rule out an intake leak into the crankcase; that is what the test is for. Yes, there should be pressure in the CC with the PCV flipped out and engine sealed. Do not let it climb past 3 or 4 psi at most else it may blow a seal or gasket.

175psi would be right, but you can't run that with iron heads and pumpgas,on the street,even at 1400ft

Yes it does. You run whatever it takes to get your combo to live. I like 18/20 initial cuz it makes the engine real snappy down low. But in my combo that makes it impossible to sync the Tslot, so it runs lean down there unless I suffer a high idle. Then I can't drive real slow with 3.55s. Also. with 20 initial I can only run 12 to 14 more in the D, which is a royal PITA to achieve with an old Factory D. So I abandoned common consensus-thinking and just gave the engine what she wanted.

I have aluminum heads and run 185psi with the HE3037Al cam (230/237/110/@.050) on 87E10 At 10.9Scr Heavily loaded with 3.55s.But I have a dash-mounted,dial-back timing box with a range of +7/- 8degrees. By only running 14* initial,and dialing 8* out I can drive 4mph@550rpm with that combo.

With 4.56s you might be able to drive as slow as 4mph@600rpm, but there is no way yur gonna do that with 20* idle timing because she is gonna buck and jump and fart until you ride the clutch. Even at 14* she is not likely to idle down to 600 without drama. And so that is why I recommend 14* as a starting point. You are only gonna go thru that low-rpm/low-timing once every time you leave from a stop. The rest of the time you are gonna be above 2000rpm/13mph, maybe above 2500/16mph; so don't let a measly 14* scare you, cuz you make it up with rate. But first you have to limit the power-timing to what the engine can handle.And then you add Vcan later, as much as she'll take,to smooth her out. (I run 24*)

In my experience the 6-blade flex-fan doesn't work in traffic. I threw mine into the rafters in ~2003 . I shift my combo at up to 7200, so I slowed my Hi-flow pump down some with pulley ratios, in a preventative measure to not throw a belt. With a stick car the rpm is always up anyway, not like an automatic at all. Well the flex-fan was hopelessly overwhelmed and the coolant temp kept rising in traffic. I finally caved in after two or three summers and tossed it.I mounted up a 7-blade and had instant relief, but the viscous coupling wasn't real happy, so I tossed it and bolted up a Ford pick-up truck thermostatic-clutch, and it was smooth sailing after 2004. ........... so I cranked up the minimum water temp to 205*F and cut a hole in my hood and routed fresh cold air down the 750DP, and she went 93 in the 1/8th.

I called it D-O-N-E.