Bottom of cooling jacket: Not super thick

It's thinner than I thought at the bottom of the cooling jacket in a couple of SBM blocks checked, while planning some bore notching at the bottom of the bores for rod bolt clearance with a stroker crank, like pictured in this article:

This 436ci Small-Block Mopar Makes Big-Block Power On Pump Gas

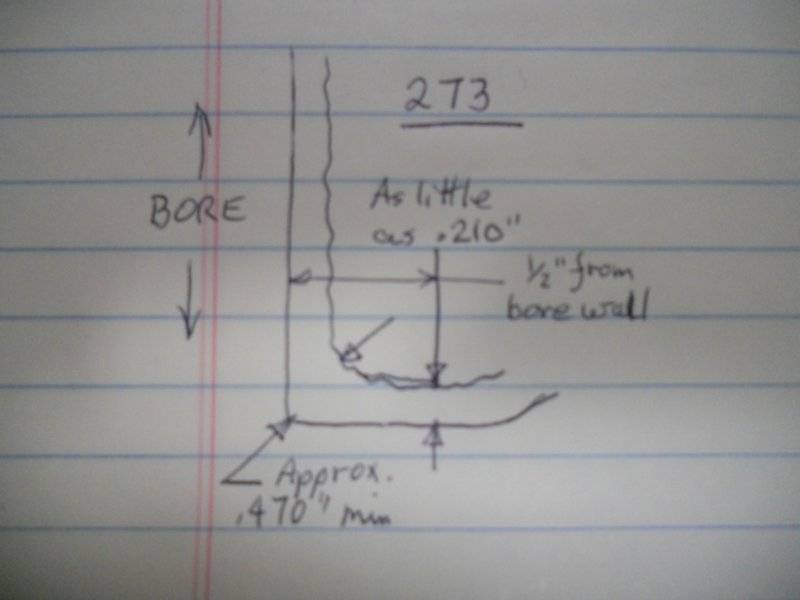

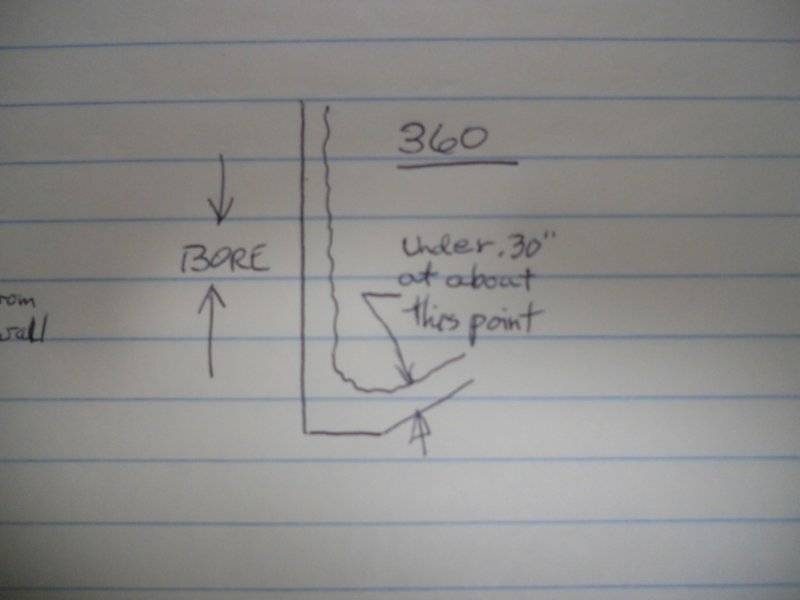

The bottom of the cooling jacket in the crankcase area on a 273 about 0.5" from the bore was sonic checked, and the thinnest areas varied between .210-.310" for all 8 bores. 2 bores were checked similarly on a 360 block and the thin areas were .275-.290". Measurements with an old style caliper in a couple of spots showed that the sonic checker was telling the truth. I always thought it was thicker down there.

Some checks of the corner thickness with the old style caliper, where the bottom of the bore ends, showed more like .45" thickness + or - at an angle through the casting.

To help visualize this, here are a couple of hand sketches of the measurements; 273 is 1st and then 360. (Sorry for the fuzzy pix).

The last pix is the 4" crank in the 273 block with a stock light SBM rod in place, showing the interference. This pix is taken at an angle where the far edge of the rod bolt's nut is moving straight away from the camera at the point of contact with the block so you can visualize the notch angle in the block compared to the far bore wall which is visible. A notch would eat about .20-.25" minimum out of the corner of the casting, where it is around .45" thick. That would seem like a lot to take out with any flexing of the block down there.

Bottom lines IMHO:

Comments, other measurements and sage experience welcomed as always!

It's thinner than I thought at the bottom of the cooling jacket in a couple of SBM blocks checked, while planning some bore notching at the bottom of the bores for rod bolt clearance with a stroker crank, like pictured in this article:

This 436ci Small-Block Mopar Makes Big-Block Power On Pump Gas

The bottom of the cooling jacket in the crankcase area on a 273 about 0.5" from the bore was sonic checked, and the thinnest areas varied between .210-.310" for all 8 bores. 2 bores were checked similarly on a 360 block and the thin areas were .275-.290". Measurements with an old style caliper in a couple of spots showed that the sonic checker was telling the truth. I always thought it was thicker down there.

Some checks of the corner thickness with the old style caliper, where the bottom of the bore ends, showed more like .45" thickness + or - at an angle through the casting.

To help visualize this, here are a couple of hand sketches of the measurements; 273 is 1st and then 360. (Sorry for the fuzzy pix).

The last pix is the 4" crank in the 273 block with a stock light SBM rod in place, showing the interference. This pix is taken at an angle where the far edge of the rod bolt's nut is moving straight away from the camera at the point of contact with the block so you can visualize the notch angle in the block compared to the far bore wall which is visible. A notch would eat about .20-.25" minimum out of the corner of the casting, where it is around .45" thick. That would seem like a lot to take out with any flexing of the block down there.

Bottom lines IMHO:

- Don't go wild with such notches and smooth all the corners nicely.

- The 'stroker cleared' dimensions on rods like the SCAT's (and maybe Eagles) have their value in all this; they stick out about .125-.150" less towards the lower edge of the bore than these stock light SBM rods.

Comments, other measurements and sage experience welcomed as always!