KB's in a 318 with No Re-balance

So how to do this? Making new pistons pins is an involved and precise process…. not for the home shop gearhead. 273 2 BBL pins nominally weigh 211 grams, so those would work, but I seriously doubt you will find NOS, and using used ones has one issue: they are ¼” shorter than the KB pins, and so may not work right with the pin locks. So the approach of adding a mild steel sleeve inside the existing pin has been taken.

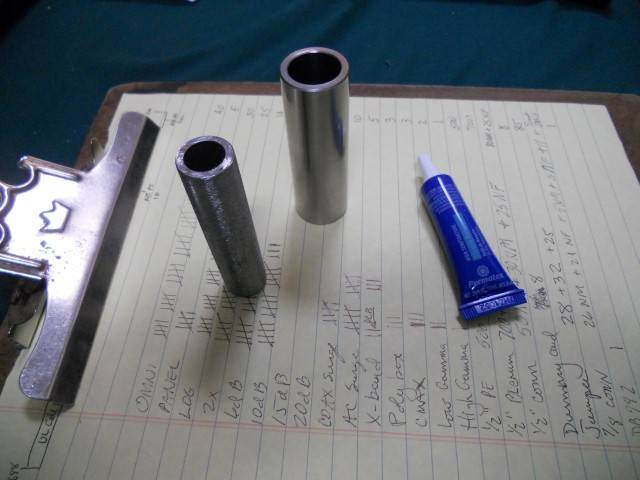

It works out that a mild steel sleeve turned down from .75”ODx.51”ID DOM tubing (.120” wall thickness) adds just the right amount of weight for the KB167 for the 318 bobweight. If different pin weight changes are desired, like for KB399 domed 318 pistons, then a different wall thickness DOM tubing can be used.

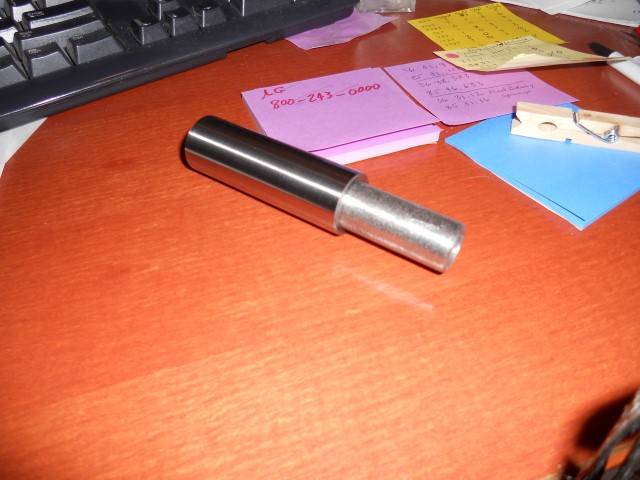

The ID of the tool steel KB pin for the KB 167 piston is .730” so the tubing has to be turned down. I don’t have a lathe but made a mandrel from a 6” long grade 5 bolt, set up to chuck 3” tubing lengths into a ½” chuck hand drill. When the drill was spun at low speed, and the tube held against a grinding wheel, this acts as a crude lathe grinding setup up. It took very frequent checking to correct tapers with this sort of deal, but it worked. The end result was a very good fit, at .001-.003” clearance inside the KB pin.

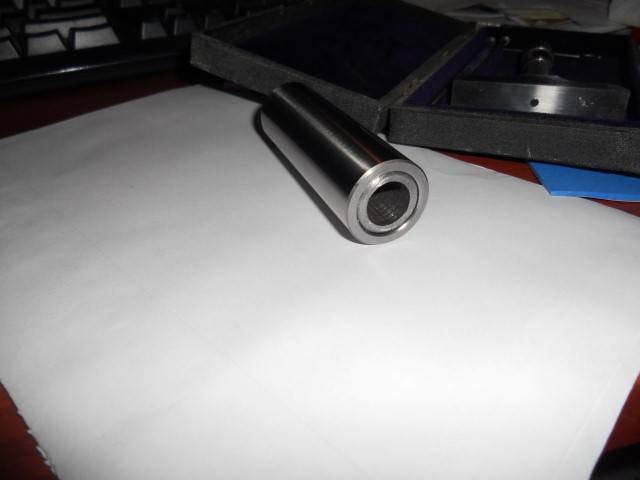

Sleeve length was set at 2.990” which is .020” shorter than the 3.010” KB pin length. This is to make sure the sleeve’s ends will be slightly recessed in the pin, so that only the pin rides on the pin locks when installed.

So how to do this? Making new pistons pins is an involved and precise process…. not for the home shop gearhead. 273 2 BBL pins nominally weigh 211 grams, so those would work, but I seriously doubt you will find NOS, and using used ones has one issue: they are ¼” shorter than the KB pins, and so may not work right with the pin locks. So the approach of adding a mild steel sleeve inside the existing pin has been taken.

It works out that a mild steel sleeve turned down from .75”ODx.51”ID DOM tubing (.120” wall thickness) adds just the right amount of weight for the KB167 for the 318 bobweight. If different pin weight changes are desired, like for KB399 domed 318 pistons, then a different wall thickness DOM tubing can be used.

The ID of the tool steel KB pin for the KB 167 piston is .730” so the tubing has to be turned down. I don’t have a lathe but made a mandrel from a 6” long grade 5 bolt, set up to chuck 3” tubing lengths into a ½” chuck hand drill. When the drill was spun at low speed, and the tube held against a grinding wheel, this acts as a crude lathe grinding setup up. It took very frequent checking to correct tapers with this sort of deal, but it worked. The end result was a very good fit, at .001-.003” clearance inside the KB pin.

Sleeve length was set at 2.990” which is .020” shorter than the 3.010” KB pin length. This is to make sure the sleeve’s ends will be slightly recessed in the pin, so that only the pin rides on the pin locks when installed.