Suspension and frame work, cracked LCA, advice welcome

Hi people,

This might be a long thread but once guys here are really good at helping members I decided to give it a try...

Finally decided to give my 76 Dart some attention after sitting in the garage for too long.

I just want to fix some old issues and make it a reliable weekend drive for short trips and riding around, all stock and spending just what is really necessary.

This Dart (4 door 318TF904) was my 1st car, all stock from factory, bought it when I was 18 and the car was 5.5 years old, all I could afford at that time. Not too long to find out the POs treated it like ****, still a great running V8, and I have a personal connection with it.

Drove it only about 15,000 mi then, till I got a more fuel efficient vehicle for DD.

Now, decided to do whatever it needs, give it a new life and fix the major issues, which are mostly suspension and framework (besides some little hidden rust and lousy paintjob).

I plan on posting some good amount of pics of my work progress and would really appreciate comments (good or bad) from experts, as well as suggestions on what might be wrong.

So far I have disassembled all under the car and found out some issues.

Cracked LCA -

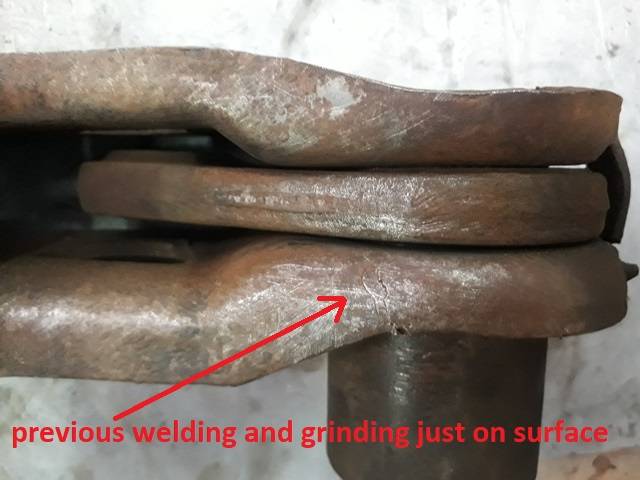

The Left LCA has a 3/4" long crack, pictures attached.

This A body was assembled in Brazil where I currently live and some parts were pressed here, but it seems that the issues are pretty much the same.

The cracked LCA must have been added to the car after a crash involving mostly the left front suspension/frame before I got it, I suspect.

The LCA crack has signs of a previous superficial welding and grinding with little penetration IMO.

These parts are not available to buy here except if I buy from the US an pay about 300% on top of that for freight and duties so I decided to fix it myself.

I plan on arch weld it after grinding a kind of V shape channel on top of the crack in order to replace the metal between both pieces.

Any suggestions as far as fixing it? I do not have MIG, plan on using arch weld, 7018 electrode or maybe 6013?

Any previous experiences of successful LCA welding? I also plan on welding some reinforcement straps on the bottom.

The K member looks good as far as cracking (so far).

Another issue is about the frame... after some measuring I suspect the left front end is off by 1/2" (higher), probably from hitting something with the left front wheel. Will post pics and more info later.

Thanks for your input.

Hi people,

This might be a long thread but once guys here are really good at helping members I decided to give it a try...

Finally decided to give my 76 Dart some attention after sitting in the garage for too long.

I just want to fix some old issues and make it a reliable weekend drive for short trips and riding around, all stock and spending just what is really necessary.

This Dart (4 door 318TF904) was my 1st car, all stock from factory, bought it when I was 18 and the car was 5.5 years old, all I could afford at that time. Not too long to find out the POs treated it like ****, still a great running V8, and I have a personal connection with it.

Drove it only about 15,000 mi then, till I got a more fuel efficient vehicle for DD.

Now, decided to do whatever it needs, give it a new life and fix the major issues, which are mostly suspension and framework (besides some little hidden rust and lousy paintjob).

I plan on posting some good amount of pics of my work progress and would really appreciate comments (good or bad) from experts, as well as suggestions on what might be wrong.

So far I have disassembled all under the car and found out some issues.

Cracked LCA -

The Left LCA has a 3/4" long crack, pictures attached.

This A body was assembled in Brazil where I currently live and some parts were pressed here, but it seems that the issues are pretty much the same.

The cracked LCA must have been added to the car after a crash involving mostly the left front suspension/frame before I got it, I suspect.

The LCA crack has signs of a previous superficial welding and grinding with little penetration IMO.

These parts are not available to buy here except if I buy from the US an pay about 300% on top of that for freight and duties so I decided to fix it myself.

I plan on arch weld it after grinding a kind of V shape channel on top of the crack in order to replace the metal between both pieces.

Any suggestions as far as fixing it? I do not have MIG, plan on using arch weld, 7018 electrode or maybe 6013?

Any previous experiences of successful LCA welding? I also plan on welding some reinforcement straps on the bottom.

The K member looks good as far as cracking (so far).

Another issue is about the frame... after some measuring I suspect the left front end is off by 1/2" (higher), probably from hitting something with the left front wheel. Will post pics and more info later.

Thanks for your input.