You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

318 Poly Vibration

- Thread starter matthon

- Start date

-

No one has posed this question so let me be the first. What is your criteria for comparing TO? In other words, what's a good vehicle to you? If you're comparing this to a newer EFI car, forget it. So far from your videos, I see nothing abnormal. Of course, I'm not there either. This is going to be very difficult to diagnose online. Where are you located? Surely there's a member around your neck of the woods that'd be willing to come over and give you a hand diagnosing this. You'd feed um and buy the beer, right?

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

66 318 poly bolted to my 64 727.

The engine/trans fit together without issue.

Just to clarify, the ring gear and converter are one piece, which was new to me at the time but probably the norm.

I'm not sure what you mean by the other way around:

If you have an early converter on a later engine could be a problem, won’t bolt together the other way around

The engine/trans fit together without issue.

Just to clarify, the ring gear and converter are one piece, which was new to me at the time but probably the norm.

I'm not sure what you mean by the other way around:

If you have an early converter on a later engine could be a problem, won’t bolt together the other way around

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Food and beer is a small price to pay for sanity.

I'm comparing it to how it ran from the first time I ran it on July 20th to Oct 5th when it first started vibrating.

I was all over this car after July 20th, brakes soup to nuts, upholstering the interior myself, tearing everything apart, constantly moving it around, then driving it full time from Aug 20th on.

The damn thing was as smooth as silk, especially at idle. I mean heck, the day before it started vibrating I left it idling for 30 minutes with zero concerns.

I agree, and I've stated it before to others, it's my own personal alien abduction, some people are skeptical, some think I'm downright crazy, some don't believe me at all. I need to find a fellow abductee who can tell me I'm not crazy.

I did not know there were two different converter snout sizes.

How does that work, one fits just right, and the other is too small?

It can't be too big, right?

I'm comparing it to how it ran from the first time I ran it on July 20th to Oct 5th when it first started vibrating.

I was all over this car after July 20th, brakes soup to nuts, upholstering the interior myself, tearing everything apart, constantly moving it around, then driving it full time from Aug 20th on.

The damn thing was as smooth as silk, especially at idle. I mean heck, the day before it started vibrating I left it idling for 30 minutes with zero concerns.

I agree, and I've stated it before to others, it's my own personal alien abduction, some people are skeptical, some think I'm downright crazy, some don't believe me at all. I need to find a fellow abductee who can tell me I'm not crazy.

I did not know there were two different converter snout sizes.

How does that work, one fits just right, and the other is too small?

It can't be too big, right?

Last edited:

Ok. So that's a good comparison. SO we have some laid ground work. Describe in detail what hard parts were changed. As in anything that spins or is connected to something that spins.

Have you double and triple checked that the balancer hasn't slipped?

Have you double and triple checked that the balancer hasn't slipped?

Schenectady, NY. Food and beer is a small price to pay for sanity.

I'm comparing it to how it ran from the first time I ran it on July 20th to Oct 5th when it first started vibrating.

I was all over this car after July 20th, brakes soup to nuts, upholstering the interior myself, tearing everything apart, constantly moving it around, then driving it full time from Aug 20th on.

The damn thing was as smooth as silk, especially at idle. I mean heck, the day before it started vibrating I left it idling for 30 minutes with zero concerns.

I agree, and I've stated it before to others, it's my own personal alien abduction, some people are skeptical, some think I'm downright crazy, some don't believe me at all. I need to find a fellow abductee who can tell me I'm not crazy.

I did not know there were two different converter snout sizes.

How does that work, one fits just right, and the other is too small?

It can't be too big, right?

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Meaning the metal and rubber slipping out of wack?

It doesn't appear to have slipped, and from what I know sometimes it's difficult to see.

I can certainly check again.

Isn't the poly internally balanced? But even so, a slipped balancer would be an issue I take it.

Would a 4 speed flywheel off a big block bolt to the 318 poly?

I have no desire to, but pulling the trans and using another flywheel to start it and isolate the engine seems reasonable. Must stress, not wanting to do that.

It doesn't appear to have slipped, and from what I know sometimes it's difficult to see.

I can certainly check again.

Isn't the poly internally balanced? But even so, a slipped balancer would be an issue I take it.

Would a 4 speed flywheel off a big block bolt to the 318 poly?

I have no desire to, but pulling the trans and using another flywheel to start it and isolate the engine seems reasonable. Must stress, not wanting to do that.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Hard parts, forgot.

Engine, used water pump on it, alternator new, uses existing power steering pump, converter/trans, driveshaft, axle.

New belts, dizzy.

Brakes new, front bearings.

Left the balancer and flexplate on new engine.

Disconnected all belts/accessories, no change.

Engine, used water pump on it, alternator new, uses existing power steering pump, converter/trans, driveshaft, axle.

New belts, dizzy.

Brakes new, front bearings.

Left the balancer and flexplate on new engine.

Disconnected all belts/accessories, no change.

The earlier converter (yours) has a smaller diameter snout than later engines..... I think 66 or 67 and after. You can “bolt together just fine” the smaller size into the later crank with the bigger hole, then the flex plate bolts are the only thing centering the converter to the crank and in a short time you will have problems. You can check this by unbolting the flex plate from the converter- if you can wiggle the converter around off of center when it is up against the crank then you have a problem there. I’m just throwing out ideas here. I really didn’t see any bad vibration problems in your videos.

The earlier converter (yours) has a smaller diameter snout than later engines..... I think 66 or 67 and after. You can “bolt together just fine” the smaller size into the later crank with the bigger hole, then the flex plate bolts are the only thing centering the converter to the crank and in a short time you will have problems. You can check this by unbolting the flex plate from the converter- if you can wiggle the converter around off of center when it is up against the crank then you have a problem there. I’m just throwing out ideas here. I really didn’t see any bad vibration problems in your videos.

This is what I am runnin through my mind. @Charrlie_S is da man with this stuff. Hopefully he will chime in. I cannot remember where the year break is from one size crank flange to the next but he knows all about that.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Next: unbolting the flex plate from the converter to see if I can wiggle the converter around off of center.

I would imagine it would destroy the converter seal, eventually, but no leaks yet.

I'll also see what info I can locate on when the snout size changed, not that my converter has never been changed, but it would be nice to know.

Hopefully I can do this asap, maybe this weekend.

This at least gives me something solid to check, thank you a ton.

I would imagine it would destroy the converter seal, eventually, but no leaks yet.

I'll also see what info I can locate on when the snout size changed, not that my converter has never been changed, but it would be nice to know.

Hopefully I can do this asap, maybe this weekend.

This at least gives me something solid to check, thank you a ton.

Charrlie_S

Well-Known Member

The earlier converter (yours) has a smaller diameter snout than later engines..... I think 66 or 67 and after. You can “bolt together just fine” the smaller size into the later crank with the bigger hole, then the flex plate bolts are the only thing centering the converter to the crank and in a short time you will have problems. You can check this by unbolting the flex plate from the converter- if you can wiggle the converter around off of center when it is up against the crank then you have a problem there. I’m just throwing out ideas here. I really didn’t see any bad vibration problems in your videos.

Just trying to remember, here. Been a long time since I worked on a "poly". If I remember correctly, the poly engines only had the big trans (727 style), with the big converter pocket in the end of the crank. So I don't think it is possible to wind up with a converter/engine mismatch, as I don't think there is a 904 bell that can bolt up to the poly engine.

The problem with converter/engine match ups occurs between 1967 down and 1968 up with the "LA" small blocks , and slant six engines. Not with the "A" (poly) series engines.

.So I don't think it is possible to wind up with a converter/engine mismatch, as I don't think there is a 904 bell that can bolt up to the poly engine.

The back of the poly(A series) block is the same as all LA engines. The sb trannys all will bolt up to them.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

I found information, mostly on fabo, that supports the post from Charrlie_S.

My understanding is:

1962 the crank changed from an extended 8 bolt crank, that used a cast iron trans, to the modern 6 bolt with an aluminum trans.

1962-66 318 polys came with the same crankshaft register as the 273/318/340 engines.

The exception is the 1964-7 273 crank has a smaller crank register, (and slant 6 engines).

I asked the prior owner of the 318 if he could send a pic or measure the original converter snout, then I could compare to my original crank. If the snout was small and my crank register large, that scenario would give me an answer. Doesn't seem likely.

I'm not sure unbolting the flex plate from the converter to see if it is loose is a good use of time at this point.

I need something concrete to check dammit!

To clarify, I describe the vibration as a frequency, because where it manifests itself reminds me of a tuning fork.

That was what I was trying to demonstrate in a few of the videos.

Lost again.

My understanding is:

1962 the crank changed from an extended 8 bolt crank, that used a cast iron trans, to the modern 6 bolt with an aluminum trans.

1962-66 318 polys came with the same crankshaft register as the 273/318/340 engines.

The exception is the 1964-7 273 crank has a smaller crank register, (and slant 6 engines).

I asked the prior owner of the 318 if he could send a pic or measure the original converter snout, then I could compare to my original crank. If the snout was small and my crank register large, that scenario would give me an answer. Doesn't seem likely.

I'm not sure unbolting the flex plate from the converter to see if it is loose is a good use of time at this point.

I need something concrete to check dammit!

To clarify, I describe the vibration as a frequency, because where it manifests itself reminds me of a tuning fork.

That was what I was trying to demonstrate in a few of the videos.

Lost again.

Last edited:

Charrlie_S

Well-Known Member

I found information, mostly on fabo, that supports the post from Charrlie_S.

My understanding is:

1962 the crank changed from an extended 8 bolt crank, that used a cast iron trans, to the modern 6 bolt with an aluminum trans.

That's what I forgot about. Thanks for the reminder.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Yes, I ran it at least twice with the belts off.

I went as far as running it with only one belt on, then the other. I don't know why or what I thought I would find.

I'm thinking the consensus is the issue is not within the engine itself.

I am unable to get a new trans mount, it's just not available for a 64 b-body, and only rubber engine mounts.

I have my old motor mounts and damper.

Should I swap those in and see what happens?

Thank you to all who have stuck with me on this, I feel we're closing in on it.

I went as far as running it with only one belt on, then the other. I don't know why or what I thought I would find.

I'm thinking the consensus is the issue is not within the engine itself.

I am unable to get a new trans mount, it's just not available for a 64 b-body, and only rubber engine mounts.

I have my old motor mounts and damper.

Should I swap those in and see what happens?

Thank you to all who have stuck with me on this, I feel we're closing in on it.

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Time to beat this dead horse some more.

I have started it to move it around over the winter, on a trickle charger, always fires right up and idles fine, for a while.

Pulled it out today, same as above. After a little bit kick the choke off, idles fine, a little more time, starts to idle down farther, too far to stay running at a light. Not yet warmed up totally.

Took it for an hour drive on back roads. Wanted to stall at stop signs. About a half hour in, would stay running at stop, but barely, and like crap.

The below vids are after the hour. That 4 blade fan sure makes quite the breeze.

Put it in drive then reverse.

The seatbelt buckle was chattering like crazy, which demonstrated the vibration I feel all the time.

Decided to Jurassic Park the vibration.

My dual quad 383 doesn't shake a bit.

If anyone can see/hear anything it would be appreciated.

I was thinking on getting a new carb, not sure what, or even why, just to eliminate it maybe as it's the only thing left not new I believe.

Going to try to drive it all week and see what happens.

I have started it to move it around over the winter, on a trickle charger, always fires right up and idles fine, for a while.

Pulled it out today, same as above. After a little bit kick the choke off, idles fine, a little more time, starts to idle down farther, too far to stay running at a light. Not yet warmed up totally.

Took it for an hour drive on back roads. Wanted to stall at stop signs. About a half hour in, would stay running at stop, but barely, and like crap.

The below vids are after the hour. That 4 blade fan sure makes quite the breeze.

Put it in drive then reverse.

The seatbelt buckle was chattering like crazy, which demonstrated the vibration I feel all the time.

Decided to Jurassic Park the vibration.

My dual quad 383 doesn't shake a bit.

If anyone can see/hear anything it would be appreciated.

I was thinking on getting a new carb, not sure what, or even why, just to eliminate it maybe as it's the only thing left not new I believe.

Going to try to drive it all week and see what happens.

Try this. When it’s still running with out stalling. Put foot on brake,Put it into gear, push gas pedal to the floor and hold it there for 20-30 seconds. If the motor starts to slow down and wants to start out while ur still holding it to the floor u found ur problem. Torque converter is no good. Put back into park, shut it off , prepare to pull tranny so u can change the converter. Pull the pan off tranny to see if there is filings in it. Report back. Kim

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

Just tried it, wasn't stalling, large open side street, foot on brake, put in gear, foot to floor, rpms go to just above 2k and car starts to move.

Attempt #2, same result.

Not able to pull pan now.

Immediately after, car now has severe clunking sound only when driving and turning right - not when going straight, backwards, or left.

Noticed on way to work, completed multiple large circles in parking lot, only when turning right.

Do not feel it in steering, suspension, or braking. Sounds centrally located, yet not sure. Thought maybe ball and trunion, but only on right turn?

And really don't want to blame the b&t, it took the max wedge abuse, right?

100% new brakes, 4 wheel power drum, Booster Dewey booster, adjusted perfectly, stops great.

In drive or reverse, 2 barrel carb if that matters, car will pull extremely well at first flick of throttle. This is one reason why I don't just turn the idle up to avoid stalling at stop, because if it is running better it idles too high to comfortably put into gear.

Quickly devolving into I don't know what.

I can't separate engine from trans as the ring gear is on the converter, unless I pull it, drain it, and bolt converter to flexplate.

But after this test, which was enlightening and a darn good one, I'm doubting the converter is the issue - and add a new issue.

And I can't get the radio to work!

Attempt #2, same result.

Not able to pull pan now.

Immediately after, car now has severe clunking sound only when driving and turning right - not when going straight, backwards, or left.

Noticed on way to work, completed multiple large circles in parking lot, only when turning right.

Do not feel it in steering, suspension, or braking. Sounds centrally located, yet not sure. Thought maybe ball and trunion, but only on right turn?

And really don't want to blame the b&t, it took the max wedge abuse, right?

100% new brakes, 4 wheel power drum, Booster Dewey booster, adjusted perfectly, stops great.

In drive or reverse, 2 barrel carb if that matters, car will pull extremely well at first flick of throttle. This is one reason why I don't just turn the idle up to avoid stalling at stop, because if it is running better it idles too high to comfortably put into gear.

Quickly devolving into I don't know what.

I can't separate engine from trans as the ring gear is on the converter, unless I pull it, drain it, and bolt converter to flexplate.

But after this test, which was enlightening and a darn good one, I'm doubting the converter is the issue - and add a new issue.

And I can't get the radio to work!

matthon

Well-Known Member

- Joined

- Aug 29, 2008

- Messages

- 2,981

- Reaction score

- 1,352

I believe I now have a resolution to both issues: idle/stalling and vibration.

Of course, I'm hesitant in stating everything has been resolved.

Thank you everyone for reading my lengthy bs and stupidity and providing suggestions and info.

A fbbo member also provided a specific part in the carb to check.

I realize some probably called out these issues earlier, sometimes it's really difficult to see the forest when all the trees are brand new or just rebuilt!

I like using the kiss principle, which led me to swap 1 motor mount a few days ago, even though both are brand new, I checked them multiple times, removed one once too.

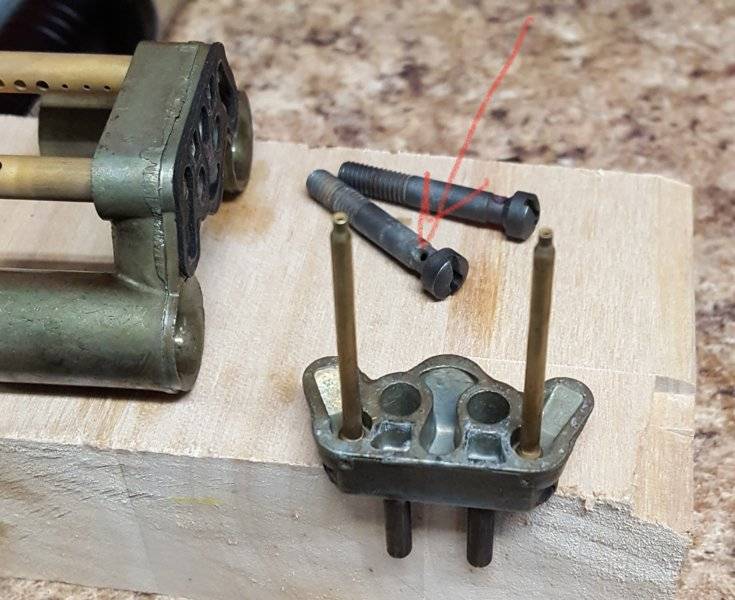

The old one is brick hard, when I pulled the new one it didn't fall apart, it's not ripped or destroyed, I put it in a vice and it doesn't compress, it doesn't twist, nothing.

See if you see a difference in the before and after glass of water test.

Carb: I pulled the tubes out, air goes through no problem, WD40 too. Same with the hollow bolts that hold it down.

Then I noticed what appeared to be tiny threads clumped on one screw at the top 'port' just below the head.

And I mean tiny, stuck there, air didn't blow them off. New cheap toothbrush and some more cleaning/air, done.

Put it back together, idled fine. Took it for a ride, no stalling. Ran on when turned off, lowered idle screw, fixed.

Smells a tad rich, so I'll check the timing and idle mix screws in a few days.

If the new rubber mounts are that crappy, and poly mounts are expensive/unavailable, I've got a number of old mounts I can use, a few actually look very good. Plus I got a nowhere to be found poly trans mount from a fbbo member.

New parts that suck and you don't know it is the worst!

Now I need to solve the clunking only during a right hand turn issue - another thread.

I will update this again once I swap all the mounts, so we will see if that stops the vibration.

What do you think, do you see a difference in the 2 videos?

Of course, I'm hesitant in stating everything has been resolved.

Thank you everyone for reading my lengthy bs and stupidity and providing suggestions and info.

A fbbo member also provided a specific part in the carb to check.

I realize some probably called out these issues earlier, sometimes it's really difficult to see the forest when all the trees are brand new or just rebuilt!

I like using the kiss principle, which led me to swap 1 motor mount a few days ago, even though both are brand new, I checked them multiple times, removed one once too.

The old one is brick hard, when I pulled the new one it didn't fall apart, it's not ripped or destroyed, I put it in a vice and it doesn't compress, it doesn't twist, nothing.

See if you see a difference in the before and after glass of water test.

Carb: I pulled the tubes out, air goes through no problem, WD40 too. Same with the hollow bolts that hold it down.

Then I noticed what appeared to be tiny threads clumped on one screw at the top 'port' just below the head.

And I mean tiny, stuck there, air didn't blow them off. New cheap toothbrush and some more cleaning/air, done.

Put it back together, idled fine. Took it for a ride, no stalling. Ran on when turned off, lowered idle screw, fixed.

Smells a tad rich, so I'll check the timing and idle mix screws in a few days.

If the new rubber mounts are that crappy, and poly mounts are expensive/unavailable, I've got a number of old mounts I can use, a few actually look very good. Plus I got a nowhere to be found poly trans mount from a fbbo member.

New parts that suck and you don't know it is the worst!

Now I need to solve the clunking only during a right hand turn issue - another thread.

I will update this again once I swap all the mounts, so we will see if that stops the vibration.

What do you think, do you see a difference in the 2 videos?

-