Off the top of my head

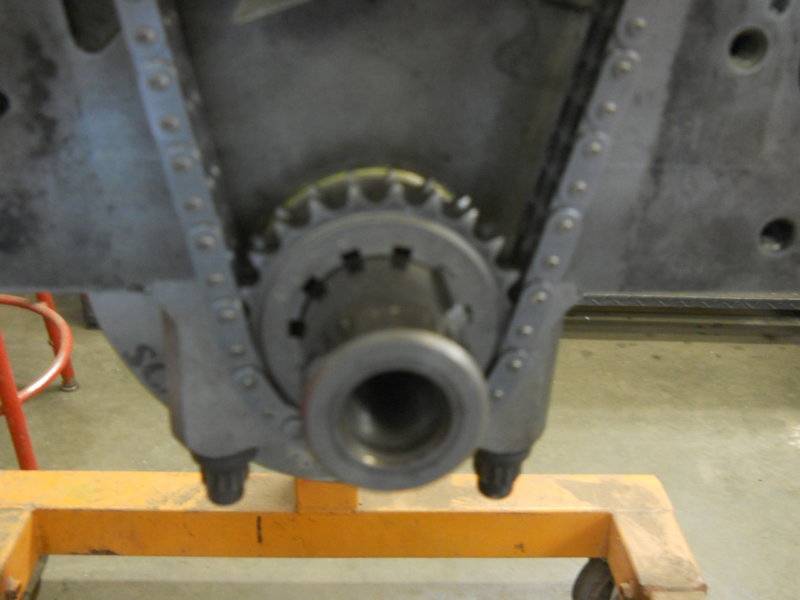

Resto block 956 deck 4.070 bore

King bearings

total seal rings, this time.

Indy360-1 heads, A disaster out of the box very poor quality, Seats and bowl blend. also stem height out

686 solid Comp roller

T&D rockers radius d for springs Poor quality out of the box

Smith bros pushrods this time.

Oiling mods several.

1050 quick fuel.

Carter pump

fluiddamper

5500 stall

456 742

I had help from a Troyer modified Nascar shop owner. Tony Hirshman. His son Tony works for Kyle Bush. His son Matt Hirshman is a Champion driver.

They helped with all the plumbing due due cooling problems. I had access to all supplies I needed. Hence all the plumbing on the car . any thing you needed was right there. No ordering and waiting.

Ended up being the radiator was not flowing air .Tubes swelled from a previous motor failure. Took a long time to find that. The rad was new with one failure. Shady Dells build.

His buddies at Carlisle warned me. I didn't listen. They said let him do your Batten heads he was the only one with the guides but don't leave him with any parts you want in your motor. He will switch them out .He did

My son knows all the details of the new motor.

Since then we bought the equipment and do our own work. A new bed mill for block work. and some other machines my son bought recently. He is working on a fixture for head seat work. He also just bought a fixture for truing lifter bores and installing bronze bushings BB , Hemi and SB.

Being able to do our own work is a game changer with cost and quality. Who does the average guy trust with motor work? You can't see whats inside until it's to late.

Oh yeah they had to pay me for all the parts to build this motor. Still lost all the labor cost. I would not give him a third chance. Thats right there were two. One never made it on the Dyno. 2 X-blocks destroyed by Ryan.

You can build a Ford or Chevy off the shelf they sell every combo you can think of. Mopars need good machinist. There are few out there that have the knowledge. And then do they have accurate new equipment.

we couldn't afford a Rottler at over 100k. But these millports came up on Ebay. They build the rottlers . He stole it at $12,500 new still on the pallet. They came from a business that went belly up and are being sold in Buffalo NY. by a salvage company. They are still on ebay . Type in millport. You will never find a new one this cheap in your life time.

View attachment 1715290529

View attachment 1715290530

View attachment 1715290531

View attachment 1715290532

View attachment 1715290533

View attachment 1715290534

View attachment 1715290535

View attachment 1715290536