Need Any Welding advice?

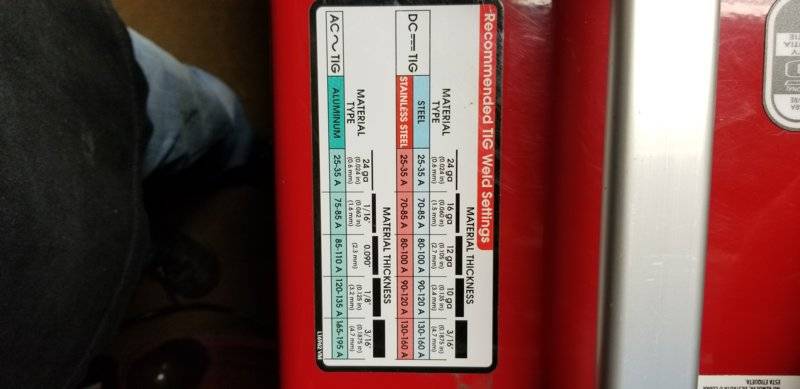

Question number one AC for tig aluminum current depends on thickness I will send pix

Question number 2 as someone else has said I don't think stick should be used in automotive work sheet metal Chrome Molly , ECT

Number 3

It's hard to recommend a machine if you haven't used it but there is a lot of good machines out there I went in halves with my son and bought a Lincoln 200 Square wave ACD C stick machine plus pulse real nice machine but a little pricey But we bought it brand new and it's been a great machine but if you want ACD C you're gonna need to spend a little more

Number 4

It's Been years since I have done it but it's kinder lighting with Teague few start of puddle which means you're removing metal then you dip your rod and add the metal back in you can kind of do that with gas welding but we used to do is start a puddle and just keep running the ponnelle down until you've made your Weld it's kind of hard to explain sorry head Bang

Number 5

As my son is taught me you really need the heat to be adjustable there's a lot of variables like gas flow cup size tungsten size X cetera

Number 6

I don't mean to be a DICK But it's kind of obvious don't Weld or do anything that uses electrical current in water that's my disclaimer

Number 7

Did you mean tick rod I just bought a pound of IR80S - D2 for micro Mali 4 link tubes your net was $12.22 from mcmaster C pic

Number 8

I'm not sure I would think it would depend on how much Room you have head Bang maybe someone else that has done Roll bars which I have seen many threads in FABO

Well I hope this helps the OP and some of you other guys out there if there is any questions or welding advice I would be more than happy to ask my son since he has learned from one of the best welders who may I add works for Lockheed and has been considered 1 of the best in the country picks to follow

Gary, and son Kevin which is not the son who owns the dart but his brother and kudos to him for helping me build this car.

Well since I'm still new to the forum and I'm an OLD FART I've been welding on and off for 35 years And the best thing I did was try to teach my son how to Weld he got so intrested in it he went to school for it in the last 3 years hes become a multiple certificate pipe welder and in the last 4 or 5 months hes been working for an aerospace company doing aerospace Welding. Since it is quite different than doing pipe welding . So here goes

Question number one AC for tig aluminum current depends on thickness I will send pix

Question number 2 as someone else has said I don't think stick should be used in automotive work sheet metal Chrome Molly , ECT

Number 3

It's hard to recommend a machine if you haven't used it but there is a lot of good machines out there I went in halves with my son and bought a Lincoln 200 Square wave ACD C stick machine plus pulse real nice machine but a little pricey But we bought it brand new and it's been a great machine but if you want ACD C you're gonna need to spend a little more

Number 4

It's Been years since I have done it but it's kinder lighting with Teague few start of puddle which means you're removing metal then you dip your rod and add the metal back in you can kind of do that with gas welding but we used to do is start a puddle and just keep running the ponnelle down until you've made your Weld it's kind of hard to explain sorry head Bang

Number 5

As my son is taught me you really need the heat to be adjustable there's a lot of variables like gas flow cup size tungsten size X cetera

Number 6

I don't mean to be a DICK But it's kind of obvious don't Weld or do anything that uses electrical current in water that's my disclaimer

Number 7

Did you mean tick rod I just bought a pound of IR80S - D2 for micro Mali 4 link tubes your net was $12.22 from mcmaster C pic

Number 8

I'm not sure I would think it would depend on how much Room you have head Bang maybe someone else that has done Roll bars which I have seen many threads in FABO

Well I hope this helps the OP and some of you other guys out there if there is any questions or welding advice I would be more than happy to ask my son since he has learned from one of the best welders who may I add works for Lockheed and has been considered 1 of the best in the country picks to follow

Gary, and son Kevin which is not the son who owns the dart but his brother and kudos to him for helping me build this car.