You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1972 Duster Build with my Daughter

- Thread starter Jim Kueneman

- Start date

-

Too long of a break.... Last weekend was a record snow storm and I was digging out and getting snow off the flat roof.... while fighting off a cold. 14" of that white stuff..... Feeling better now, and the snow is gone. 70F this weekend, more like it.

Spent this evening after work getting ready for the vinyl top. masked off, roof scuffed with 320 grit, cleaned with SPI 700 Wax and Grease remover.

Some hints here. Mark where the trim clips are. The are a bugger to find after the fact..

Now find the middle of the front and rear glass opening and mark.

Now find the width of the top between the front to back seams.

Take half that measurement from the center each direction front and back openings.

Now run tape front to back with the inside of the tap lined up with the inside of the seam

The Coronet I wrapped the top around the drip rail because the trim was made for the vinyl top. This one I am not going to do that so I masked off the face of the drip rail and will cut the top flush with the top and only catch the lip of the drip rail trim because the trim is likely not for a vinyl top car..

This will be the guide tomorrow. Got out the wife clothes steam machine and filled it with water.

Look what the UPS man brought....

So here is a great series on installing vinyl tops. The host Pete is ding-dong and a hack but this one he goes to a real shop that installs tops and this is how I am going to do it. The trick of the steamer is new to me so I will see if that makes the job easier.... And they are doing an A Body!

Spent this evening after work getting ready for the vinyl top. masked off, roof scuffed with 320 grit, cleaned with SPI 700 Wax and Grease remover.

Some hints here. Mark where the trim clips are. The are a bugger to find after the fact..

Now find the middle of the front and rear glass opening and mark.

Now find the width of the top between the front to back seams.

Take half that measurement from the center each direction front and back openings.

Now run tape front to back with the inside of the tap lined up with the inside of the seam

The Coronet I wrapped the top around the drip rail because the trim was made for the vinyl top. This one I am not going to do that so I masked off the face of the drip rail and will cut the top flush with the top and only catch the lip of the drip rail trim because the trim is likely not for a vinyl top car..

This will be the guide tomorrow. Got out the wife clothes steam machine and filled it with water.

Look what the UPS man brought....

So here is a great series on installing vinyl tops. The host Pete is ding-dong and a hack but this one he goes to a real shop that installs tops and this is how I am going to do it. The trick of the steamer is new to me so I will see if that makes the job easier.... And they are doing an A Body!

JDMopar

Well-Known Member

I helped a pro put the vinyl top on my Superbird, and he did it the same way, with the exception of going side to side vs back to front. Found the center of roof and vinyl the same way, and then lined up one seam and started stretching. I can see where it would work either way. Good luck, and be patient!

Did not get the top on. Kaelyn came home and took the drivers test on line and passed... I knew what was coming next.... "can we go to town and get it".... yes we went, had dinner and she drove part way home..... She promised to get up early and put in a full day tomorrow.

threewood

Well-Known Member

Congrats! Now she can drive your Coronet to the HEMI show

Congrats! Now she can drive your Coronet to the HEMI show

Well now that she has her permit she said she don't want to go next weekend and she wants to get her Duster done.....

It does not seem like it should take a lot of work but vinyl tops are a PIA.....

Dug out the Harbor Freight sprayer and after 20 minutes and glue everywhere I put it where it deserved....

I used my real paint gun and it worked great with a 2mm needle. It was getting old and I was going to delegate it to a primer gun anyway...

This makes SO MUCH DIFFERENCE IT IS NOT POSSIBLE TO SAY IT IN WORDS..... The wife clothes steamer saved the day....

Peeled off the tape.

THE PAPER IS A BIG BIG BIG MISTAKE... Don't do this...

It stuck so we waited for it to dry then used a razor to scrape it clean. After words we shot a bit more glue for good measure..

Here is the secret, use 6 mil plastic sheet. It is strong enough so it won't rip when pulling on it. This made the rest of the day go much better... Here the center is done and we are doing the side..

Dug out the Harbor Freight sprayer and after 20 minutes and glue everywhere I put it where it deserved....

I used my real paint gun and it worked great with a 2mm needle. It was getting old and I was going to delegate it to a primer gun anyway...

This makes SO MUCH DIFFERENCE IT IS NOT POSSIBLE TO SAY IT IN WORDS..... The wife clothes steamer saved the day....

Peeled off the tape.

THE PAPER IS A BIG BIG BIG MISTAKE... Don't do this...

It stuck so we waited for it to dry then used a razor to scrape it clean. After words we shot a bit more glue for good measure..

Here is the secret, use 6 mil plastic sheet. It is strong enough so it won't rip when pulling on it. This made the rest of the day go much better... Here the center is done and we are doing the side..

Now we shot the roof...

Here is the 6 mil plastic that keeps it from sticking before you want it to.

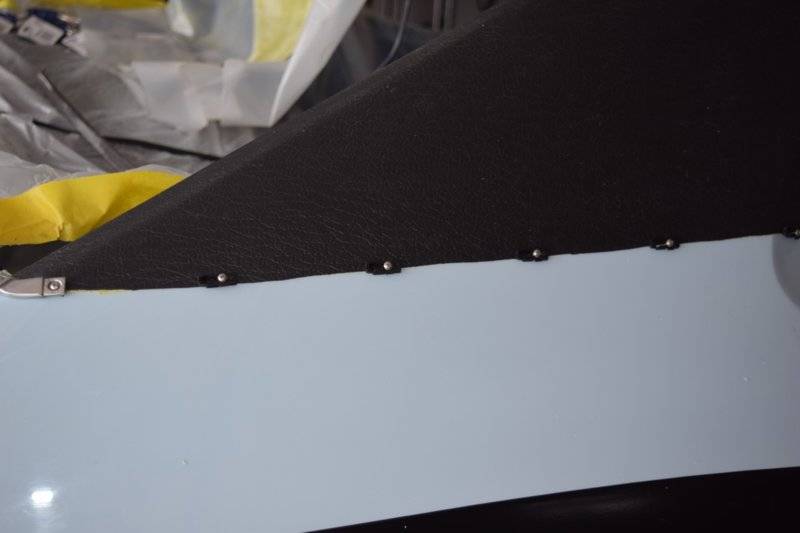

Side is done. We placed the trim where it belonged then taped the top and bottom. Now I can cut down the center directly under the trim.

Just like that. Notice how I cut relief cuts to allow it to relax into the drip channel. I bought 2 plastic glass bones from Steel Rubber when I ordered the front and back glass gasket a few weeks ago. They worked great to heat up the vinyl with the steamer then use the plastic tool to seat the material into the grooves and channels.

These are the only clips available. They are not right and to narrow. If you flip them over there are 2 tangs that will hold the trim.. It is not super tight to the body but it won't fall off..

Other side is done and we got the drip moulding polished and installed on this side.

Just like we know what we are doing!

Here is the 6 mil plastic that keeps it from sticking before you want it to.

Side is done. We placed the trim where it belonged then taped the top and bottom. Now I can cut down the center directly under the trim.

Just like that. Notice how I cut relief cuts to allow it to relax into the drip channel. I bought 2 plastic glass bones from Steel Rubber when I ordered the front and back glass gasket a few weeks ago. They worked great to heat up the vinyl with the steamer then use the plastic tool to seat the material into the grooves and channels.

These are the only clips available. They are not right and to narrow. If you flip them over there are 2 tangs that will hold the trim.. It is not super tight to the body but it won't fall off..

Other side is done and we got the drip moulding polished and installed on this side.

Just like we know what we are doing!

Last edited:

JayinMI

Well-Known Member

I use Weldwood Landau Top adhesive when wrapping parts I build. Something else that works well is non-backed automotive carpet that you haven't sprayed with adhesive. I use it frequently because we usually have some around the shop. I might try the 6mm plastic next time I do something large. Top looks great!

I use Weldwood Landau Top adhesive when wrapping parts I build. Something else that works well is non-backed automotive carpet that you haven't sprayed with adhesive. I use it frequently because we usually have some around the shop. I might try the 6mm plastic next time I do something large. Top looks great!

That is what we sprayed... Great stuff...

mopowers

Well-Known Member

That turned out great! You should be proud.

That turned out great! You should be proud.

Third one's a charm I guess?

Last edited:

Interesting...... Kaelyn canceled her sleep over with her best friend to work on the Duster tomorrow since she got her drivers permit Friday..... makes you say Mmmmmmmmmm.....

Oh $hit, where is the Advil this morning dear.....

We were whooped with the top so today was more of a wrench turning day rather than polishing (that is actually harder work than it would seem).

DMT, what would we do without Jim and his wife.....

Passenger weatherstrip rail is polished and seal installed ready for the car.

Bought these 4mm rivets that were sent from China.... It was a failure... The factory diameter is weird and the 4mm was too small... Still needing to figure this out to get the wing windows back together....

Stuck the window in just for effect but we did finish the stripes.... sort of..... It started out great.

Then the tail panel kicked our butt. Yes it is crooked and yes it is full of bubbles. Will be ordering another. The shape of the panel is not factory as I had to do body work there so the right way is to cut this into 4 parts and have an overlap in the middle. That would be much less noticeable than the eight thousand bubbles.... She voted for the Twister sticker. I think it looks great with it. I like the way she made it follow the stripe instead of level with the body line..

We got the left quarter one stripped as we messed that one up a few weeks ago. Need to order that one too.

Then we attacked the trunk. All the marker lights are in for good with new bulbs and the rear wiring is in with new bulbs. Just need to restore the taillights.

New Tanks Inc tank and OER sending unit. Not sure what they modeled the "exact duplicate OEM" from but not '72/'73. They both had much longer arms. You can't get this in with the float (at least it is a brass and not plastic float) so I stuck tape on the end to use to hold the float to maneuver it back into the clamp wire and snap it on. We dropped it in the tank 20 times before I thought of this idea..... It needed a bit of a bend as the sock hit the bottom of the tank and the flange would not sit flush.... hate aftermarket.....

Yes I pulled the OEM lock ring from one of the original tanks and did not use the cheaper thin one that came with the tank.

Kaelyn ran the wiring and I blasted and painted the filler tube. A new DMT boot (now I know the trunk mat covers this I kick myself for just not reusing the original, it just looked bad) and the body plugs are inserted.

DMT, what would we do without Jim and his wife.....

Passenger weatherstrip rail is polished and seal installed ready for the car.

Bought these 4mm rivets that were sent from China.... It was a failure... The factory diameter is weird and the 4mm was too small... Still needing to figure this out to get the wing windows back together....

Stuck the window in just for effect but we did finish the stripes.... sort of..... It started out great.

Then the tail panel kicked our butt. Yes it is crooked and yes it is full of bubbles. Will be ordering another. The shape of the panel is not factory as I had to do body work there so the right way is to cut this into 4 parts and have an overlap in the middle. That would be much less noticeable than the eight thousand bubbles.... She voted for the Twister sticker. I think it looks great with it. I like the way she made it follow the stripe instead of level with the body line..

We got the left quarter one stripped as we messed that one up a few weeks ago. Need to order that one too.

Then we attacked the trunk. All the marker lights are in for good with new bulbs and the rear wiring is in with new bulbs. Just need to restore the taillights.

New Tanks Inc tank and OER sending unit. Not sure what they modeled the "exact duplicate OEM" from but not '72/'73. They both had much longer arms. You can't get this in with the float (at least it is a brass and not plastic float) so I stuck tape on the end to use to hold the float to maneuver it back into the clamp wire and snap it on. We dropped it in the tank 20 times before I thought of this idea..... It needed a bit of a bend as the sock hit the bottom of the tank and the flange would not sit flush.... hate aftermarket.....

Yes I pulled the OEM lock ring from one of the original tanks and did not use the cheaper thin one that came with the tank.

Kaelyn ran the wiring and I blasted and painted the filler tube. A new DMT boot (now I know the trunk mat covers this I kick myself for just not reusing the original, it just looked bad) and the body plugs are inserted.

Last edited:

New bulbs tucked away until the lights are restored.

New trunk cardboard and the mat was installed. It fits as good as my Coronet, none of the notches or holes are quite right.... We have a OEM jack we bought off eBay that is till in the box. Need to open it. I think all we need is the spring to hold it down.

Kaelyn installed the screws and the filler was in.

Kaelyn polished up the original cap (she is getting good with the buffing wheel). Just need the new stripe!

Need to get some gas line and clamps and hook up the ground...

Friday I sprayed undercoating. My Coronet does not have any and it is noisy. Trying to save the chipping behind the wheels and kill the tuna can sound at the same time...

New trunk cardboard and the mat was installed. It fits as good as my Coronet, none of the notches or holes are quite right.... We have a OEM jack we bought off eBay that is till in the box. Need to open it. I think all we need is the spring to hold it down.

Kaelyn installed the screws and the filler was in.

Kaelyn polished up the original cap (she is getting good with the buffing wheel). Just need the new stripe!

Need to get some gas line and clamps and hook up the ground...

Friday I sprayed undercoating. My Coronet does not have any and it is noisy. Trying to save the chipping behind the wheels and kill the tuna can sound at the same time...

Last edited:

The Duster is very nice, I really like that your daughter is doing so much work. I think we have a lot in common, I have a 68 Coronet we {my daughter and I} finished in 2007 and we finished a 72 Demon in 2018. The Demon was done for her so we could go to shows together and she did a lot of work helping me. She got her license at 16 is 17 now and has driven both cars. Her first car to drive was the Coronet. Be proud and keep up the good work.

Last edited:

Alex5280

74' Duster

Great Job! The car is turning out gorgeous!

Red's '72 Dart

Well-Known Member

Tell Kaelyn, that she is doing a great job on her car. There is not enough women the the automotive industry! Car looks awesome!

The Duster is very nice, I really like that your daughter is doing so much work. I think we have a lot in common, I have a 68 Coronet we {my daughter and I} finished in 2007 and we finished a 72 Demon in 2018. The Demon was done for her so we could go to shows together and she did a lot of work helping me. She got her license at 16 is 17 now and has driven both cars. Her first car to drive was the Coronet. Be proud and keep up the good work.

View attachment 1715298542

Cool!

Tell Kaelyn, that she is doing a great job on her car. There is not enough women the the automotive industry! Car looks awesome!

Just realized your from Tucson! Do you take your Dart to any shows?

Red's '72 Dart

Well-Known Member

Not yet. But if I can get the time I will.

Did you just buy that? It sure look like a CraigsList car I saw a while ago....Not yet. But if I can get the time I will.

Red's '72 Dart

Well-Known Member

I found it in Phoenix. It was living in a carport with six other cars. The owner's wife made him get rid of half his cars! She got tired of parking on the curb. This was the only mopar he had.

Rear window rebuild. We did the RH side a while ago. Here is how we did it....

Again the steamer works great for loosening up old window tinting film. A razor blade and it comes right off.

Remove the rear latch screws and spring holder on the back side.

Here is how far the thick foam comes down this side.

Some reference photos for later.

The thick foam stops at the upper bracket

Reference

Drill out the rivet in the lower front corner.

Gone.

The glass will side out of the channel.

Now time to clean it all up and remove the weatherstrip.

Again the steamer works great for loosening up old window tinting film. A razor blade and it comes right off.

Remove the rear latch screws and spring holder on the back side.

Here is how far the thick foam comes down this side.

Some reference photos for later.

The thick foam stops at the upper bracket

Reference

Drill out the rivet in the lower front corner.

Gone.

The glass will side out of the channel.

Now time to clean it all up and remove the weatherstrip.

-