70Duster440

Well-Known Member

Wilwood aside, and short of machining on a lathe or going medieval with a grinder, has anyone seen a source for OEM type disc brake rotors (typical early 70's and up, 11") that have a beveled nose on the hub?

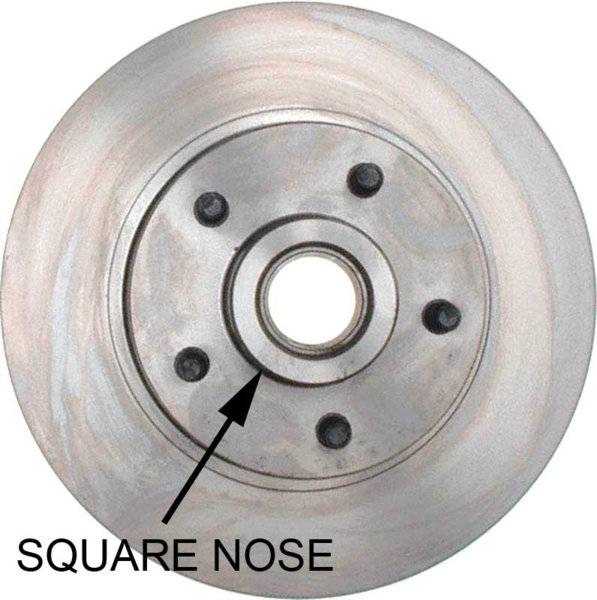

99.9% have a square nose. Dr. Diff has a photo of a beveled nose rotor but doesn't actually possess any with it. My searches have come up empty so I'm thinking they're like unicorns.

99.9% have a square nose. Dr. Diff has a photo of a beveled nose rotor but doesn't actually possess any with it. My searches have come up empty so I'm thinking they're like unicorns.